19

7/22/08

RTR10 & RTR15 Series Rotary Tillers 311-431M

Land Pride

Section 4: Maintenance and Lubrication

Table of Contents

Section 4: Maintenance and Lubrication

Maintenance

!

CAUTION

For safety reasons, each maintenance operation must be

performed with the tractor’s PTO disengaged, the Tiller

lowered completely to the ground or on safely supported

blocking, tractor engine shut off and ignition key removed.

Proper servicing and adjustment is the key to the long life

of any implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

After using your tiller for several hours, check all bolts to

be sure they are tight.

Replace any worn, damaged or illegible safety labels by

obtaining new labels form your Land Pride Dealer.

Tine Replacement

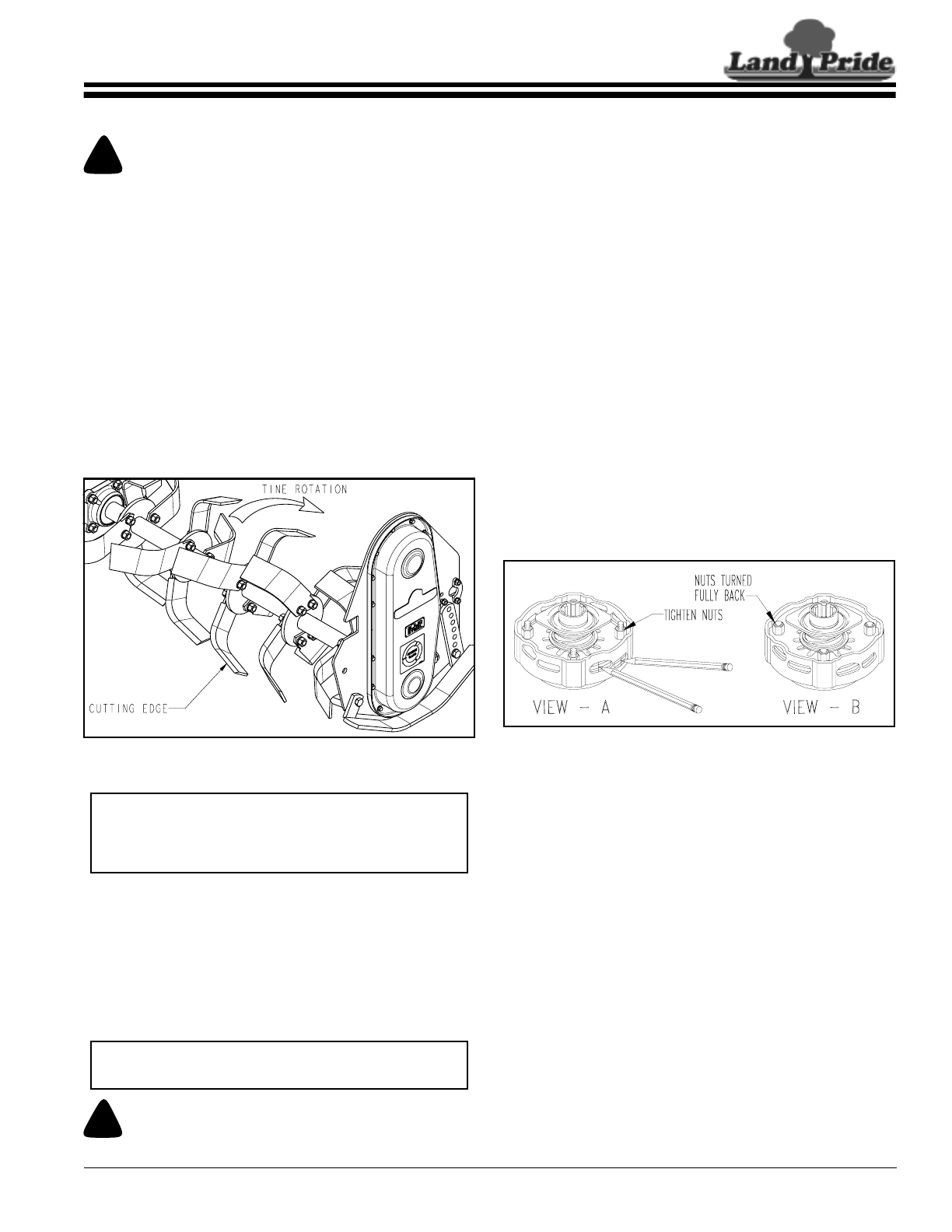

Refer to Figure 4-1:

TIne Replacement

Figure 4-1

7. Remove 2 hex head cap screws and fasteners from

each tine being replaced. Remove tine.

8. Attach each new tine to the flange making certain it is

mounted so that the cutting edge crosses over the

flange and leads in rotation as shown in Figure 4-1.

9. Replace the capscrewsand fasteners. Tighten nuts to

proper torque. See The Torque Values Chart in the

“Appendix” section on page 29.

!

WARNING

Worn tines may be very sharp!

22269

IMPORTANT: Always install tines with cutting edge

facing direction of rotor shaft rotation. When ordering

replacement tines, be sure to order both right and left

hand tines.

IMPORTANT: Replace tines with genuine Land Pride

tines only.

Driveline Protection

Tiller drive components are protected from shock loads

by either a two plate friction clutch or a shear bolt. Shear

bolt protection is discussed on page 21.

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on the friction

surfaces. Repeat “run-in” instructions at the beginning of

each season and when moisture and/or condensation

seizes the inner friction plates.

Refer to Figure 4-2 below and Figure 4-3 on page 21 to

determine which friction clutch your tiller has. Follow run-

In, disassembly and assembly instructions for your

specific clutch.

Clutches With 4 Adjusting Nuts

Clutch Run-In

Refer to Figure 4-2 (View - A):

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction disks.

2. Tighten all 4 nuts uniformly until spring load is low

enough that the clutch slips freely with PTO

engaged.

Clutches With 4 Adjusting Nuts

Figure 4-2

3. Start tractor and engage PTO for 2-3 seconds to

permit slippage of clutch surfaces. Disengage PTO,

then re-engage a second time for 2-3 seconds.

Disengage PTO, shut off tractor and remove key.

Wait for all components to stop before dismounting

from tractor.

4. Inspect clutch and ensure that the scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disk and plate are still aligned. A clutch that

has not slipped must be disassembled to separate

the friction disk plates. See “Clutch Disassembly &

Assembly” on page 20.

Refer to Figure 4-2 (View - B):

5. Turn all 4 nuts fully back if no two marks on the

friction disk and plate are still aligned. Clutch is ready

for use.

6. The clutch should be checked during first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to check for slippage.

23696