9

8/12/14

RTR12 & RTA12 Series (Serial No. 884764-) Rotary Tillers 311-785M

Land Pride

Section 1: Assembly and Set-Up

Table of Contents

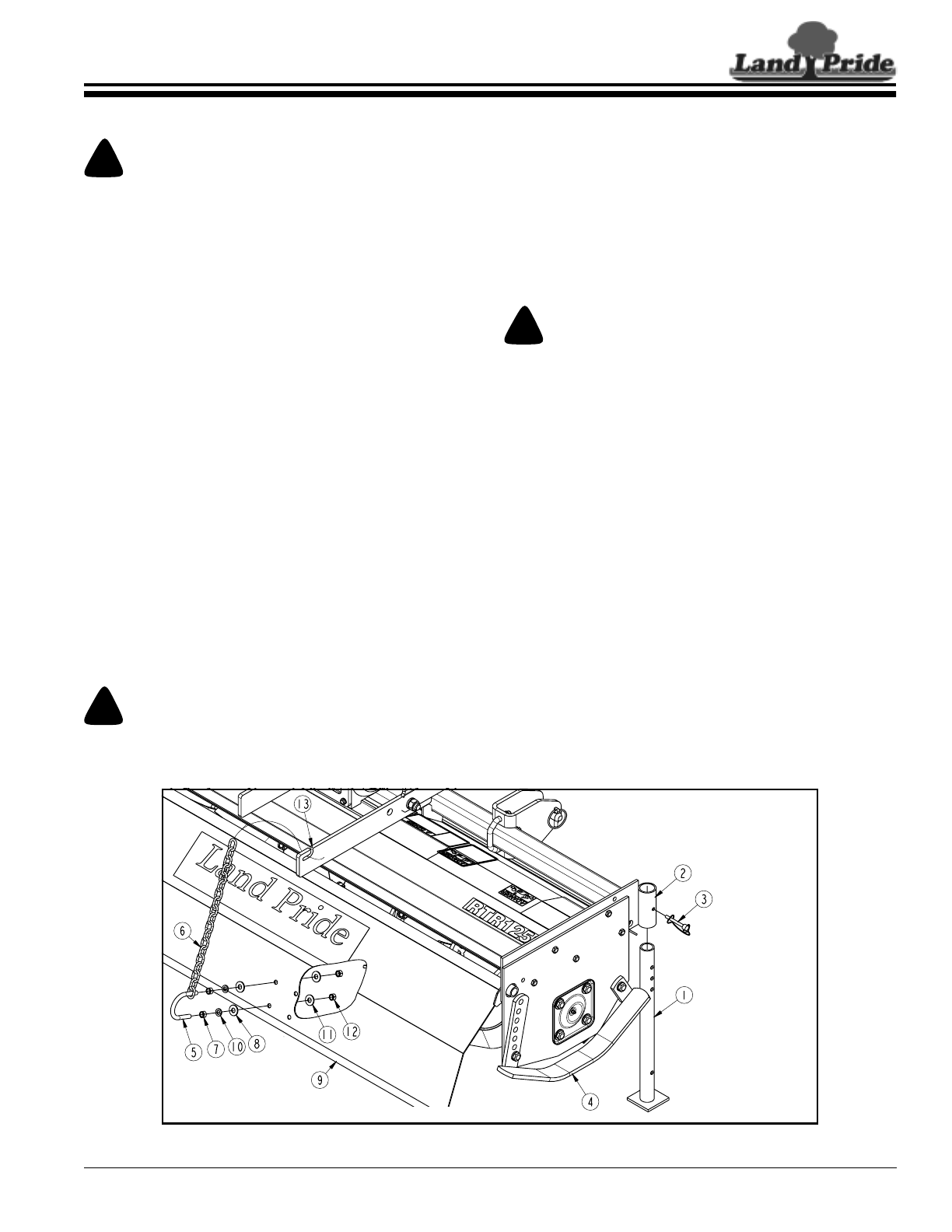

Support Leg & Rear Deflector Chain Assembly

Figure 1-1

RTR Series Shown

30728A

Section 1: Assembly and Set-Up

Torque Requirements

Check to make sure all nuts are tightened. Refer to

“Torque Values Chart” on page 32 to determine correct

torque values for common bolts. See “Additional

Torque Values” at bottom of chart for exceptions to

standard torque values.

RTR & RTA Parking Stand

Installation

Refer to Figure 1-1:

!

CAUTION

To avoid bodily injury caused by accidental falling of tiller,

stabilize unit with parking stand and support blocks.

1. Insert parking stand (#1) in support tube (#2).

2. Adjust parking stand to a height that will support the

tiller level while resting on skid shoes (#4).

3. Secure parking stand with wire retaining pin (#3).

Make sure wire retainer is hooked over the end of the

retaining pin.

RTR & RTA Rear Chain Installation

Refer to Figure 1-1:

1. Insert u-bolt (#5) into one end of rear chain (#6).

2. Install two nuts (#7) onto u-bolt an equal distance

from the threaded end.

3. Insert u-bolt through lock washers (#10), flat

washers (#8), and holes in deflector shield (#9) that

are most vertically located under slot (#13).

4. Secure u-bolt (#5) to deflector shield (#9) with flat

washers (#11) and 3/8"-16 hex nuts (#12). Draw hex

nuts (#12) up snug and tighten hex nuts (#10) to the

correct torque.

5. Attach opposite end of rear chain (#6) to slot (#13).

Dealer Preparations

!

CAUTION

To avoid bodily injury caused by accidental falling of tiller,

securely support tiller on safe supporting stands or blocks.

This unit is shipped almost completely assembled.

Carefully follow instructions for final assembly.

Before attempting assembly check the following items.

Having all the needed parts and equipment readily at

hand will speed up your assembly task and will make the

job as safe as possible.

• Check for fasteners and pins that were shipped with

the tiller. Small hardware shipped loose from the

factory is contained in a bag. Larger parts are attached

to the shipping crate.

• Have ready for the assembly task a fork lift or loader

along with chains and safety stands sized for the job.

• Have a minimum of 2 people on hand during assembly.

Tractor Requirements

Tractor horsepower should be within the range noted

below. Tractors outside the horsepower range must not

be used.

Hitch Category . . . . . . . . . . . . . . . . . . . . 3-Point Cat. I

PTO Speed . . . . . . . . . . . . . . . . . . . . . . . . .540 RPM

Horsepower Requirements:

42" & 50" widths . . . . . . . . . . . . . . . . . . .15-35 HP

58" & 66" widths . . . . . . . . . . . . . . . . . . . .20-40 HP

74" Width . . . . . . . . . . . . . . . . . . . . . . . . .25-50 HP

!

WARNING

Ballast weights may be required to maintain steering control.

Refer to your tractor Operator’s Manual to determine proper

ballast requirements.