19

Section 3: Operating Instructions

2/02/09

RC5020 (540 RPM) and RCM5020 (1000 RPM) Rotary Cutters 318-474M

Land Pride

Table of Contents

Field Set-up

!

WARNING!

The following operational procedures should be carried out by

the tractor operator. Other persons should be cleared of the

area even during cutter set-up. Cutter operation should be

stopped when in the vicinity of other persons.

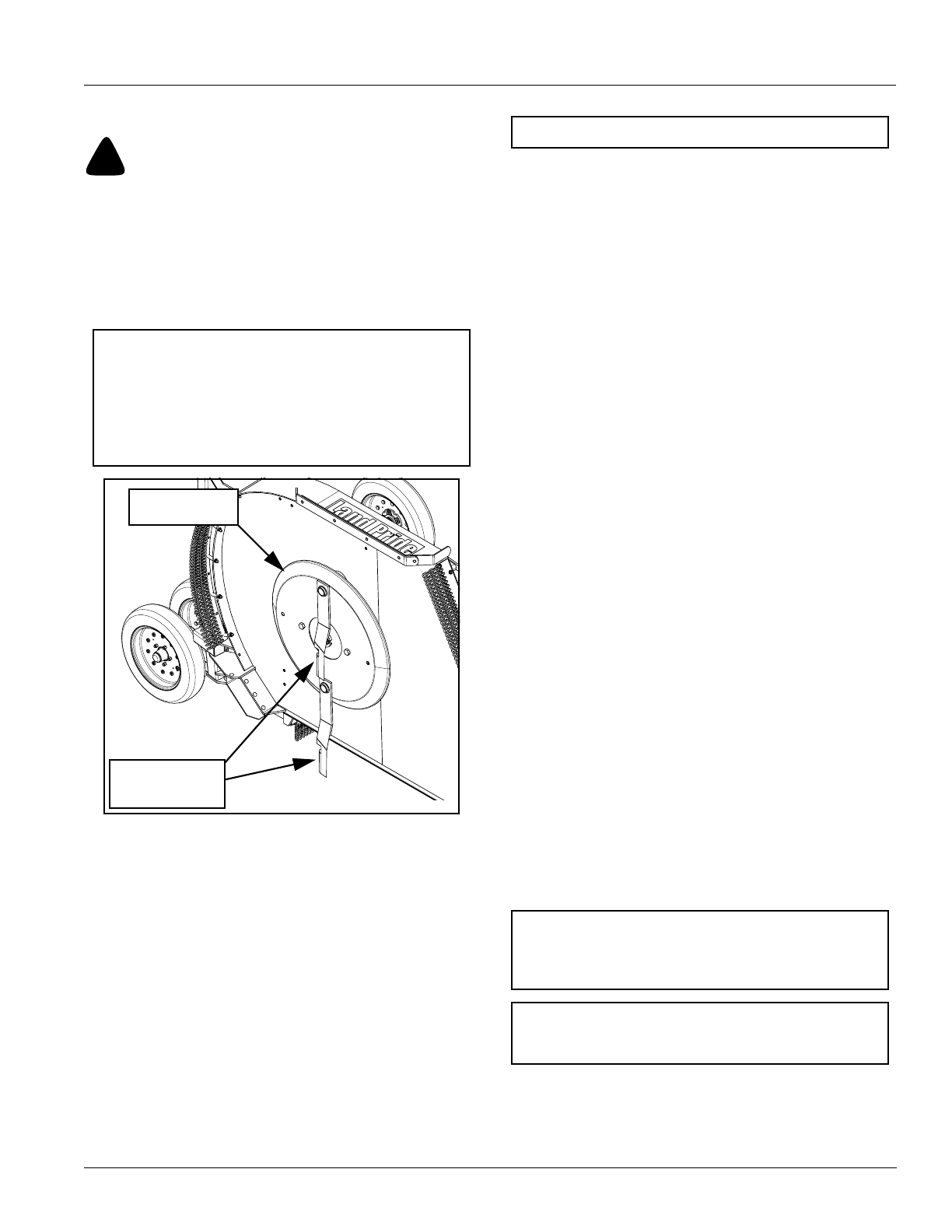

Refer to Figure 3-3:

1. Inspect wing blade carriers and cutting blades prior

to lowering the wings.

Wing Deck Blade Positioning

Figure 3-3

Refer to Figure 3-1 & Figure 3-2 on page 18:

2. Raise both wings up to release any tension on the

transport lock bar as shown in Figure 3-1. Remove

hairpin cotter (#1) from both the left and right cylinder

pins (#4).

3. Rotate end of transport lock bar (#3) to the storage

pin (#2) as shown in Figure 3-2. Secure with hairpin

cotters (#1).

4. Lower both left and right wing sections down.

5. Extend hydraulic lift cylinder to release any pressure

against the stroke control spacers. Remove stroke

control spacers. Keep spacers with tractor for field

installation.

6. Increase throttle to approximately 1/4 engine speed

and slowly engage driveline. Also see note below.

NOTE: The cutting blades may become locked

together (overlapped) when wings are raised to

transport position. Operating the cutter under such

circumstances will result in severe deck vibration.

Inspect wing decks for a locked blade condition prior

to power-on operation. Use a pry bar or other tool to

separate cutting blades when necessary.

24854

Wing Deck

Cutting Blades

Blade Carrier

7. Ensure that all power shafts are rotating and that the

cutter has no vibration.

8. Continue to increase throttle to full 540 or 1000 PTO

speed before commencing forward operation.

9. While cutting, use the lever for the hydraulic lift

cylinder to set the cutter to correct cutting height.

10. Once cutting height has been set, stop traveling,

disengage driveline, shut tractor engine off and

remove switch key. Do not change lift cylinder stroke

length.

11. Install stroke control spacers onto the lift cylinder rod

until the rod is filled between the cylinder and clevis.

Always install the largest spacers first and the

smaller ones last. If necessary, raise cutter slightly to

install the last spacer.

12. Return to the tractor and bring cutter up to full rpm as

outlined in steps 7,8&9andthen continuing cutting

operation.

Operating Speed

Refer to Figure 3-4 & Figure 3-5:

Optimum ground speed depends on density of material

being cut, horsepower rating of the tractor and (in some

cases) terrain. Always operate tractor at cutter’s full

rated PTO speed in a gear range that allows the cutter to

make a smooth cut without lugging the tractor down,

usually between 2 to 5 mph. Low PTO speed will allow

the blades to hinge back resulting in a ragged uneven

cutting.

Wing Operating Angle

Use the float position of your tractor’s hydraulic system to

provide automatic floating of the wings for varying terrain

conditions. This will ensure that the wing gauge wheels

are in continuous contact with the ground at all times.

NOTE: Use tractor’s PTO soft start option if available.

IMPORTANT: Do not operate this cutter under any

terrain conditions where, on a continuous cut, the

wing angle exceeds 45 degrees up. Damage to the

wing driveline and gearboxes can occur.

IMPORTANT: During operation, the wing lift lever(s)

must be in the float position to avoid damage to the

cylinders and axles.