TP-6069 6/03 5Section 3 Cooling System

Section 3 Cooling System

3.1 Ventilation

Engine combustion,generator cooling, and expulsion of

flammable and lethal fumes require ventilation. Provide

ventilation compliant with USCG Regulations governing

sizing of vents and other considerations.

As a rule, size each inlet- and outlet-vent area to a

minimum of 13 sq. cm/30.5 cm (2 sq. in. per ft.) of the

craft’s beam. Should this rule conflict with USCG

Regulations, follow USCG Regulations. For applications

with screened inlets, double the size (4 sq. in. per ft.) of

the hull/deckopenings. Extend the vent ducts to bilges to

expel heavier-than-air fumes.

For generator sets mounted inthe enginecompartment,

increase the air flow to allow for the generator set’s

requirements. Install optional detection devices to

cause alarm, warning, or engine shutdown should

dangerous fumes accumulate in the compartment.

See the generator set specification sheet that shipped

with the generator set for air requirements. The air intake

silencer/cleaner provides combustion air to the engine.

Do not compromise the recommended minimum

clearance of 38 mm (1.5 in.) between a duct opening and

enclosure wall. The engine/generator performance will

decline if you compromise these guidelines. See

Figure 3-1 for allowable intake restriction.

Note: ISO 3046 derates apply. See Appendix C.

Model Allowable Intake Restriction

3.5EFOZ/4EOZ 200 mm H

2

O (1.96 kPa or less)

4--125EFOZ/5--150EOZ 635 mm H

2

O (6.23 kPa or less)

Figure 3-1 Combustion Air Intake Restriction

3.2 Cooling System Components

The marine generator set’s cooling system requires the

following components.

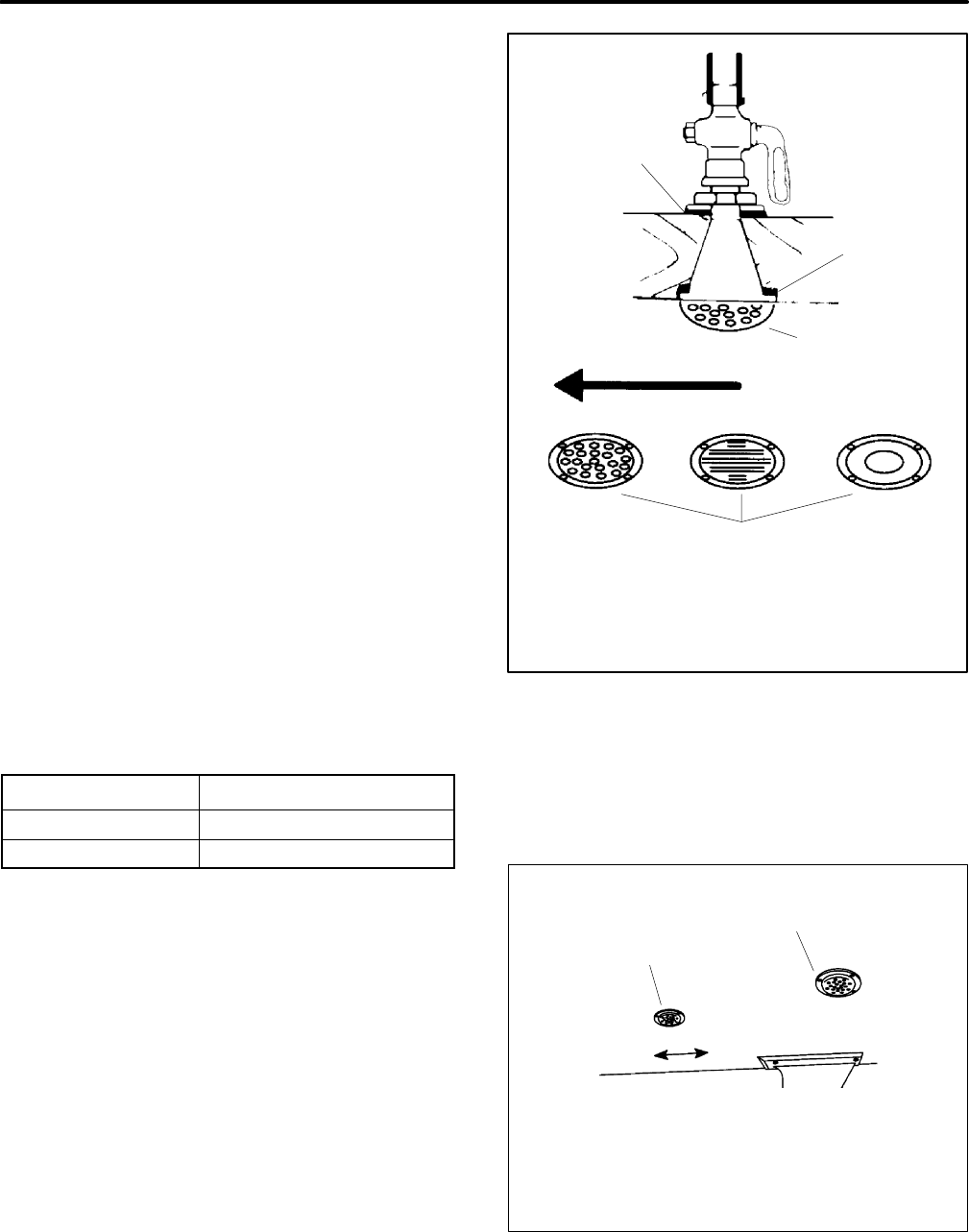

3.2.1 Intake Through-Hull Strainer

(Seacock Cover)

Install a screened-intake, through-hull strainer to

prevent entry of foreign objects. Use perforated,

slotted-hole, or unrestricted-hole design strainers. See

Figure 3-2 for examples of typical strainers. The inner

diameter of the strainer opening must be equal to or

greater than the inner diameter of the water-line hose to

the seawater pump.

1

2

3

4

5

1-789

1. Inside packing

2. Outside packing

3. Seacock cover

4. Direction of vessel movement

5. Typical intake through-hull strainers

Figure 3-2 Seacock Installation

Do not align the strainer (in relation to the craft’s direction

of travel) with any other through-hull intakes. See

Figure 3-3. Flush mount the recommended through-hull

strainer. Install slotted-hole-design strainers with the

slots parallel to the direction of the vessel’s movement.

Note: Position the intakes in relation to the vessel’s

travel so neither is in the wake of the other.

1

2

4 3

1-789

1. Generator set intake

2. Main engine intake

3. Aft (rearward)

4. Fore (forward)

Figure 3-3 Intake Strainer