28 – English

MAINTENANCE

Adjusting the start throttle speed (BC

2145)

The correct start throttle speed is set by means of an adjuster

on the rear of the handle next to the cable. Use this screw (5

mm Allen screw) to increase or decrease the start throttle

speed.

Proceed as follows:

1 Run the machine at idle.

2 Press the start throttle lock as described under the

heading Starting and stopping.

3 If the start throttle speed is too low (below 4000 rpm), turn

the adjuster screw A clockwise until the cutting

attachment starts to rotate. Then turn A clockwise a

further 1/2 turn.

4 If the start throttle speed is too high, turn the adjuster

screw A anticlockwise until the cutting attachment stops.

Then turn adjuster screw A clockwise a further 1/2 turn.

Muffler

CAUTION! Some mufflers are fitted with a catalytic converter.

See chapter on Technical data to see whether your machine

is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to direct

the exhaust gases away from the operator. The exhaust

gases are hot and can contain sparks, which may cause fire

if directed against dry and combustible material. Some

mufflers are equipped with a special spark arrestor screen. If

your machine has this type of muffler, you should clean the

screen at least once a week. This is best done with a wire

brush. On mufflers without a catalytic converter the screen

should be cleaned weekly, or replaced if necessary. On

mufflers fitted with a catalytic converter the screen should be

checked, and if necessary cleaned, monthly. If the screen is

damaged it should be replaced. If the screen is frequently

blocked, this can be a sign that the performance of the

catalytic converter is impaired. Contact your dealer to inspect

the muffler. A blocked screen will cause the machine to

overheat and result in damage to the cylinder and piston.

CAUTION! Never use a machine with a defective muffler.

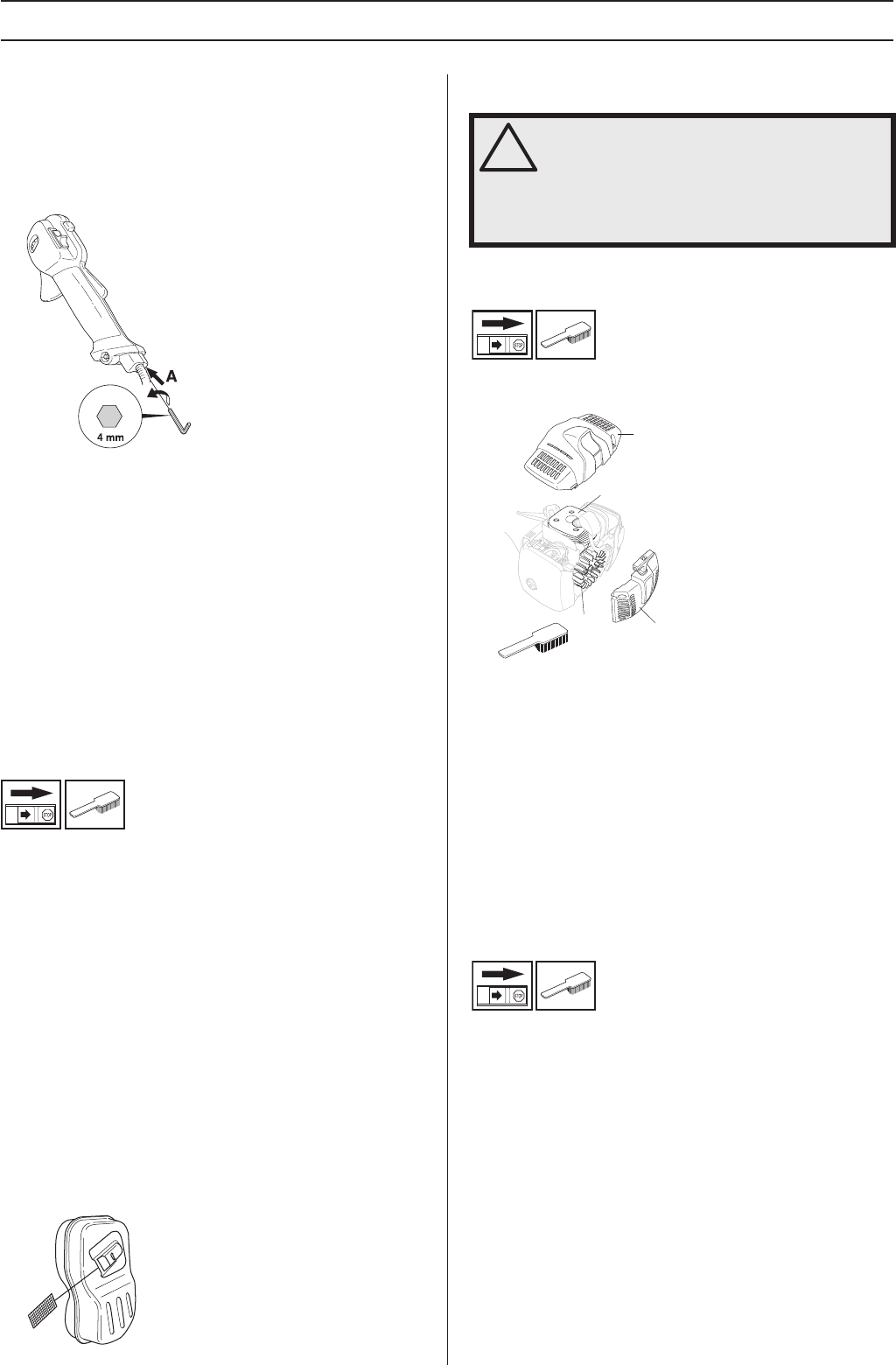

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Air intake on the starter.

2 Fins on the flywheel.

3 Cooling fins on the cylinder.

4 Cylinder cover (directs cold air over the cylinder).

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

Air filter

The air filter must be regularly cleaned to remove dust and dirt

in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts

• Excessive fuel consumption.

Clean the filter every 25 hours, or more regularly if conditions

are exceptionally dusty.

!

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

remain so for some time after stopping. This

also applies at idle speed. Contact can result

in burns to the skin. Remember the risk of

fire!

4

1

3

2