49

5

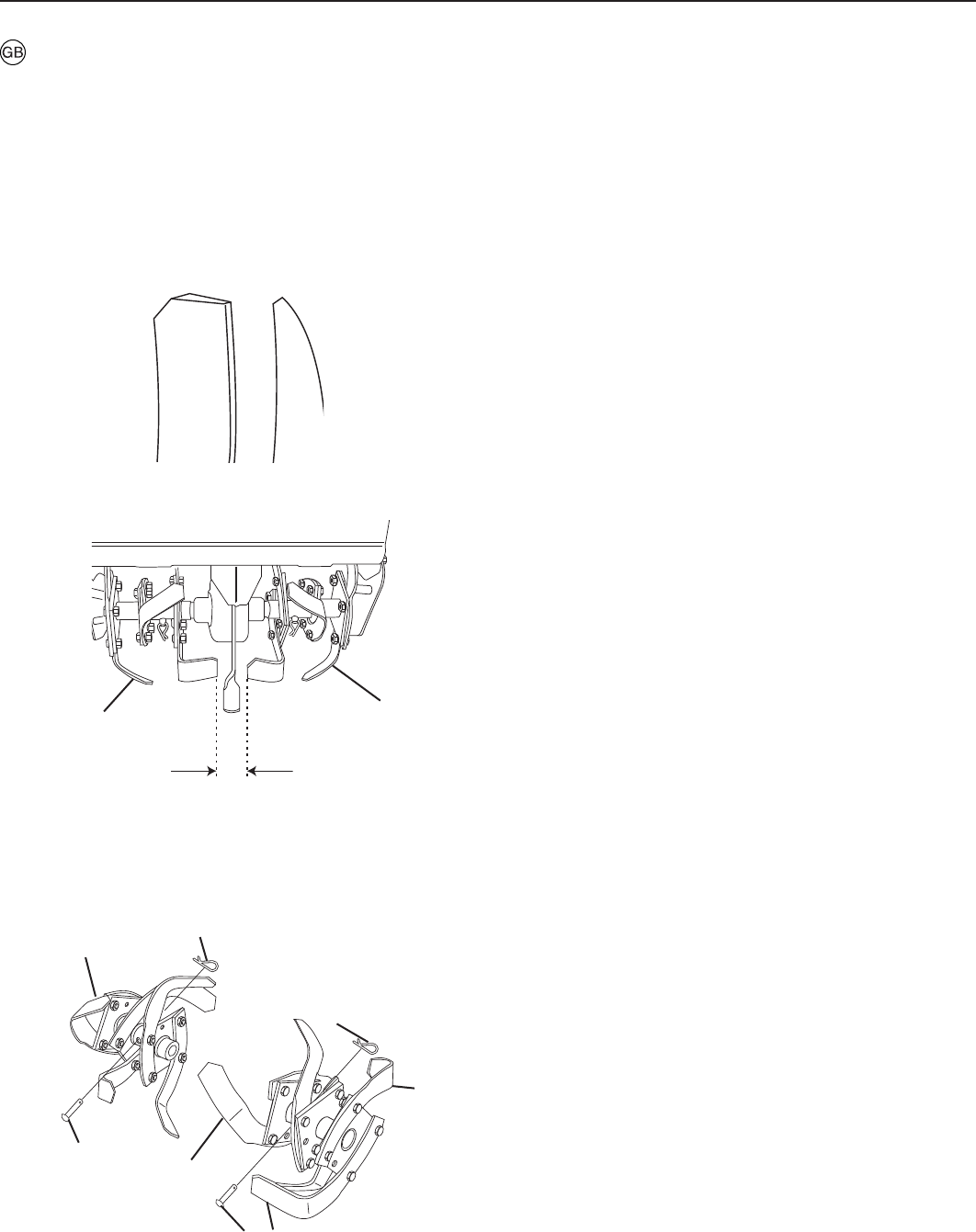

1. New tine

2. Worn tine

3. Sharp edge

4. Hairpin clip

5. Retaining pin

Figure 18

12

Ground drive belt replacement

Take to an authorized dealer for repair.

Tine replacement

A badly worn tine causes your tiller to work harder and dig

shallower. Most important, worn tines can not chop and shred

organic matter as effectively nor bury it as deeply as good

tines. A tine this worn (fig. 18) needs to be replaced.

To maintain the superb tilling performance fo this machine the

tines should be checked for sharpness, wear and bending,

particulary the tines which are next to the trans mis sion (fig.

19). If the gap between the tines exceeds 3-1/2 inches, they

should be replaced or straightened as nec es sary.

New tines should be assembled as shown in figure 20. Sharp-

ened tine edges will rotate rearward from above (fig. 20).

CAUTION!

Never tamper with the engine governor, which is factory set

for proper engine speed.

tine_3

Figure 19

Tine

Tine

3-1/2" max.

Figure 20

Counter tine

rotation

tine_13

3

4

5

5

3

3

3

4