English – 11

GENERAL SAFETY PRECAUTIONS

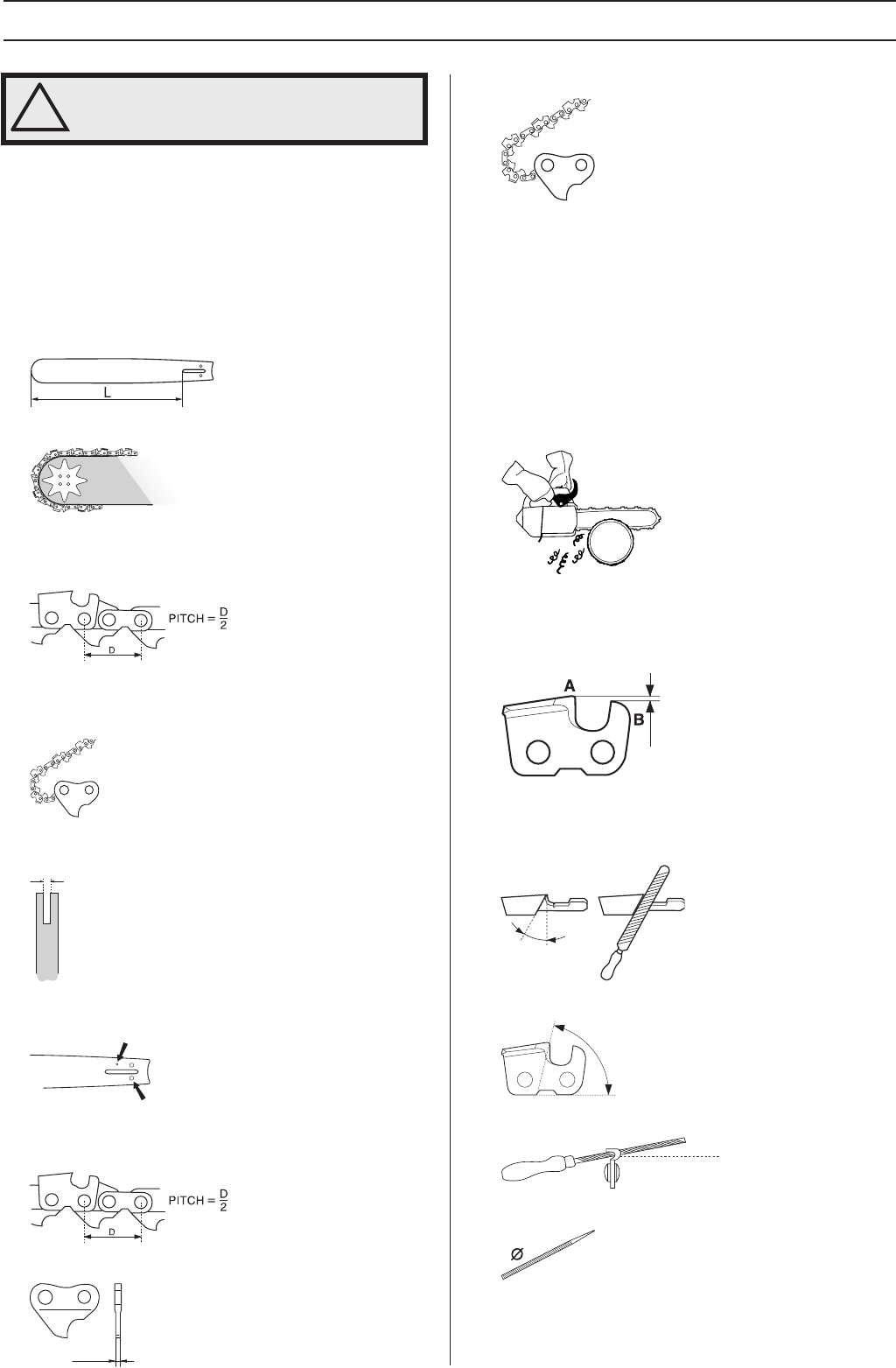

Some terms that describe the bar and chain

To maintain the safety features of the cutting equipment, you

should replace a worn or damaged bar or chain with a bar and

chain combinations recommended by Jonsered. See

instructions under the heading Technical Data for a list of

replacement bar and chain combinations we recommend.

Bar

• Length (inches/cm)

• Number of teeth on bar tip sprocket (T).

• Chain pitch (inches). The spacing between the drive links

of the chain must match the spacing of the teeth on the bar

tip sprocket and drive sprocket.

• Number of drive links. The number of drive links is

determined by the length of the bar, the chain pitch and

the number of teeth on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar must

match the width of the chain drive links.

• Chain oil hole and hole for chain tensioner. The bar must

be matched to the chain saw design.

Chain

• Chain pitch (inches)

• Drive link width (mm/inches)

• Number of drive links.

Sharpening your chain and adjusting

depth gauge setting

General information on sharpening cutting teeth

• Never use a blunt chain. When the chain is blunt you have

to exert more pressure to force the bar through the wood

and the chips will be very small. If the chain is very blunt it

will produce wood powder and no chips or shavings.

• A sharp chain eats its way through the wood and produces

long, thick chips or shavings.

• The cutting part of the chain is called the cutter and

consists of a cutting tooth (A) and the depth gauge (B).

The cutters cutting depth is determined by the difference

in height between the two (depth gauge setting).

When you sharpen a cutting tooth there are four important

factors to remember.

1 Filing angle

2 Cutting angle

3 File position

4 Round file diameter

!

WARNING! Any contact with a rotating saw

chain can cause extremely serious injuries.