ENGLISH

10

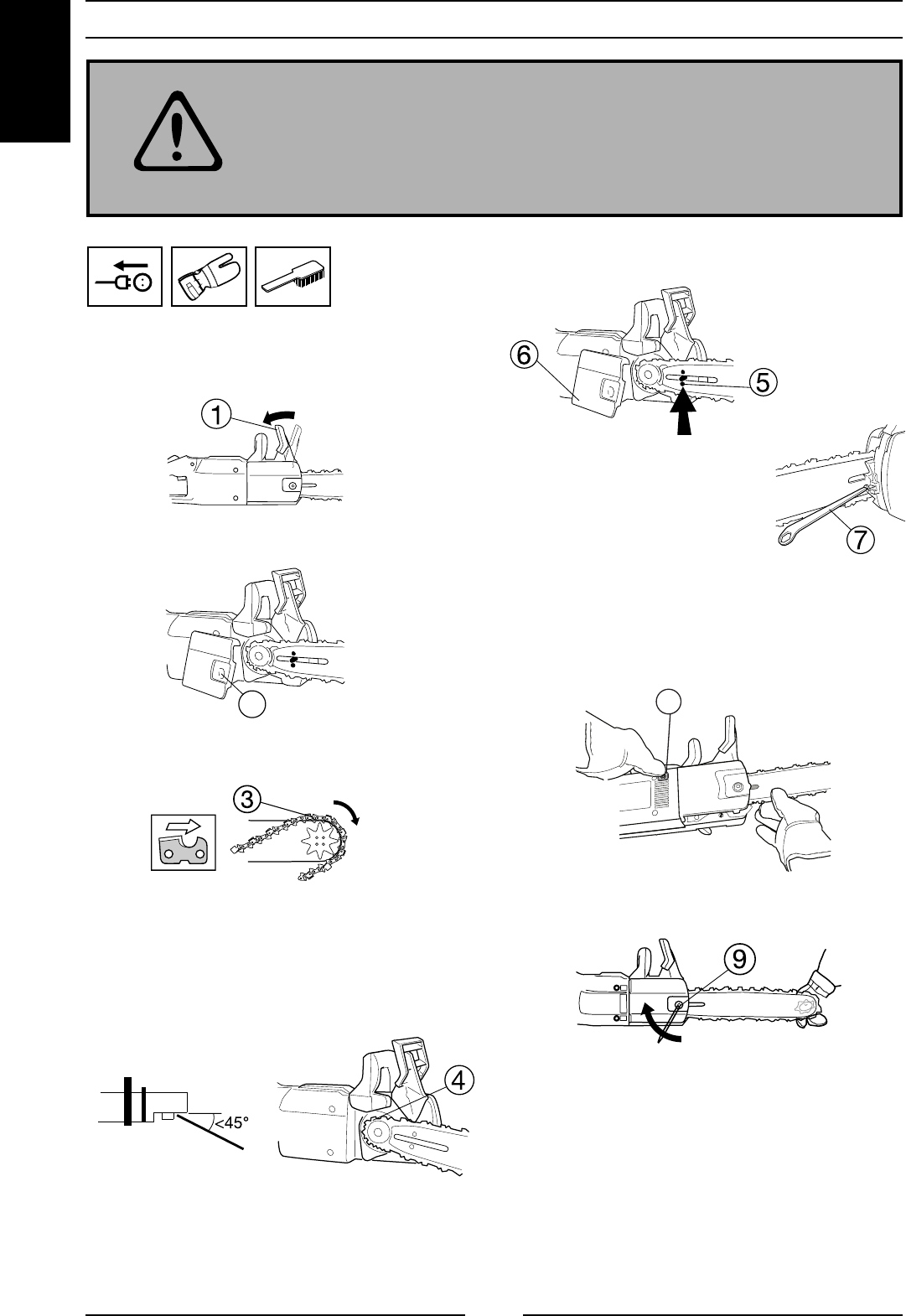

6. Replace the chain drive cover and screw

the mounting nut hand tight.

7. Tension the chain by screwing the

tensioning screw clockwise using the

screwdriver tip on the combination

tool.

8.

Tighten chain fi rmly but not so hard that it does not turn easily

by hand force. Push the button to release the chain brake. To

avoid contact between your hands and the chain, use gloves

to turn the chain.

9. Tighten the mounting nut with the combination tool while hold-

ing the tip of the guide bar up.

The tension of a new chain must be checked frequently until it

is broken in. Continue to check the tension at regular intervals

to ensure good performance and a long service life.

• Wear causes a chain to become looser with use. Regular

t ensioning is important to compensate for this wear.

• Check the chain tension at least every time you refi ll the chain

oil reservoir.

1. Pull kickback guard back against the front handle

to ensure that the chain brake is not applied.

2. Screw out the guide bar nut and remove

the chain drive cover.

3. Fit the chain around guide bar nose with

the top cutters facing forwards.

4. Holding the chain over the guide bar nose, position the

back end of the guide bar against the drive sprocket at a

45° angle to the power head. Pass the free end of the chain

around the drive sprocket, swing the guide bar into place

over the mounting bolt and against the power head, and

guide the chain into the guide bar groove.

5. Seat the guide bar tensioner pin in its hole in the guide bar.

MOUNTING GUIDE BAR AND ADJUSTING CHAIN

CAUTION!

Always disconnect power before performing cleaning or maintenance work.

CAUTION!

A loose chain can jump out of its groove during operation and cause serious

or even fatal injury.

2

8