ASSEMBLY

11

MTF−051057L

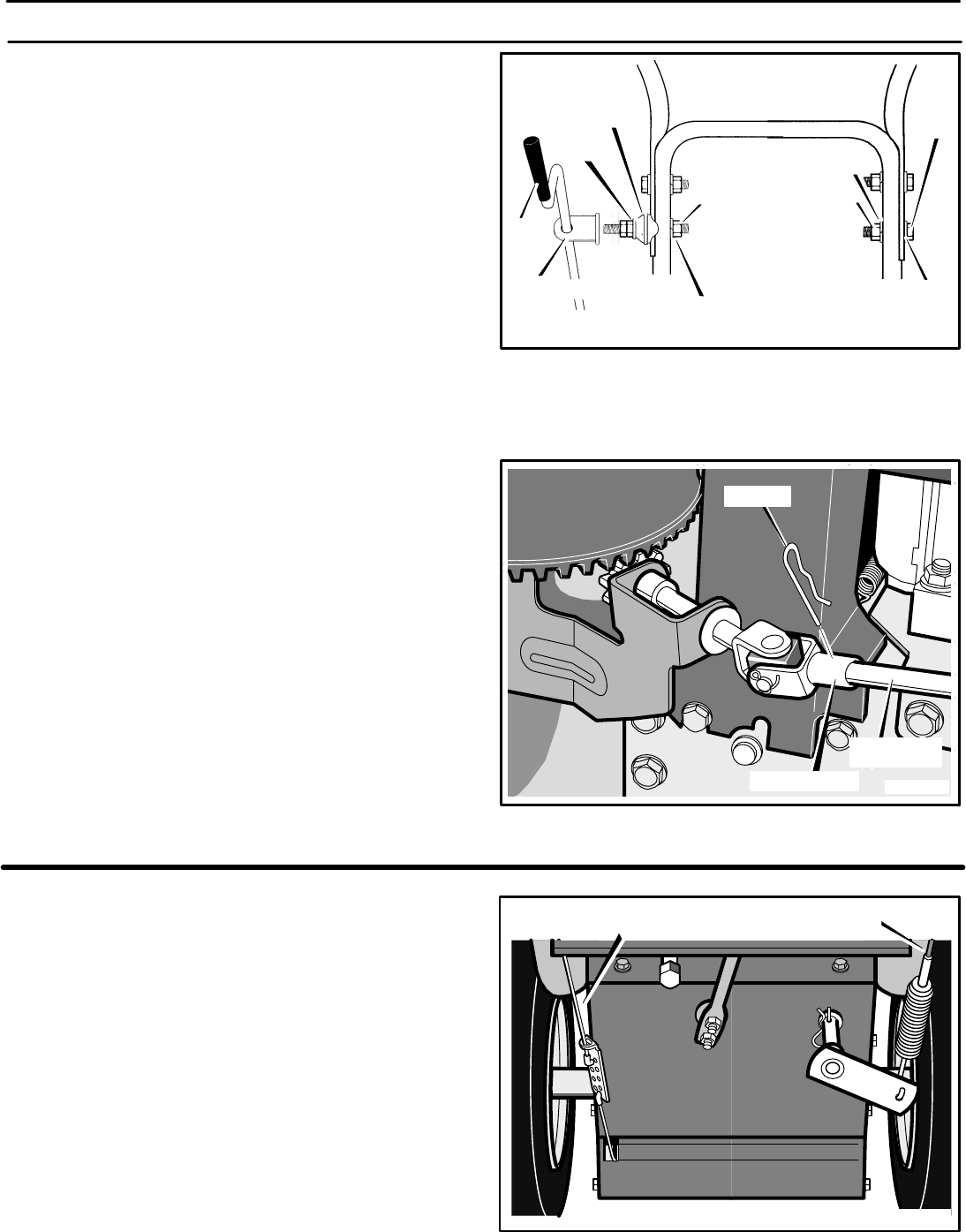

UPPER HANDLE AND CRANK ASSEMBLY

For shipping purposes, the handles were assembled

together with the fasteners in the LOWER holes. When

assembled, make sure that the fasteners are in the

UPPER holes and that the eye bolt is mounted in the

LOWER hole on the left side as shown in Figure 5.

1. On the right side of the handle, loosen, but do not remove

the fasteners (bolt, flatwasher, lockwasher and nut) that

are assembled in the lower hole.

2. On the left side of the handle, remove the fasteners (bolt,

flatwasher, lockwasher and nut) that are assembled in

the LOWER holes.

3. Remove the fasteners and the crank assembly eyebolt

from the UPPER holes of the lower handle.

4. Raise upper handle into operating position. Upper han-

dle should be to the outside of the lower handle.

NOTE: Make sure the cables are not caught between

the upper and lower handle.

5. On the left side of the handle, install the fasteners that

were removed in step 2. Make sure these fasteners are

installed in the UPPER holes as shown in Figure 5.

6. Install the fasteners and the crank assembly eyebolt that

were removed in step 3. Make sure to install the eyebolt

in the LOWER holes as shown in Figure 5. DO NOT tight-

en until all fasteners are in place.

7. Attach the crank rod to the universal joint assembly with

the hair pin (see Figure 6).

8. Tighten nut on eye bolt. Make sure eye bolt is properly

aligned and the crank can freely rotate.

9. Tighten all handle bolts.

NOTE: Make sure crank does not touch carburetor

cover.

Figure 5

Crank

Eye Bolt

Adaptor Boot

Flatwasher

Nut

Flatwasher

Bolt

Lockwasher

Flatwasher

Locknut

Figure 6

Crank Rod

Assembly

Universal Joint

Hair Pin

CHECK THE CABLES

1. If control cables have become unattached from motor

mount frame, reconnect cables as shown in Figure 7.

2. For cable adjustments, see “How To Check And Adjust

The Cables” in the MAINTENANCE section.

HOW TO SET

THE LENGTH OF THE CABLES

The cables were adjusted at the factory and no adjustments

should be necessary. However, after the handles are put in

the operating position, the cables can be too tight or too

loose. If an adjustment is necessary, see “How To Check And

Adjust The Cables” in the MAINTENANCE section.

Traction Drive Cable

Auger Drive Cable

Figure 7