Service Pressure Washer - 15

SERVICE PRESSURE WASHER

Nozzle Maintenance

A pulsing sensation felt while squeezing the spray gun trigger may

be caused by excessive pump pressure. The principal cause of

excessive pump pressure is a spray tip clogged or restricted with

foreign materials, such as dirt, etc. To correct the problem,

immediately clean the spray tip following these instructions:

1. Shut off engine and turn off water supply.

2. ALWAYS point spray gun in a safe direction, press red

button and squeeze spray gun trigger to release retained

high water pressure.

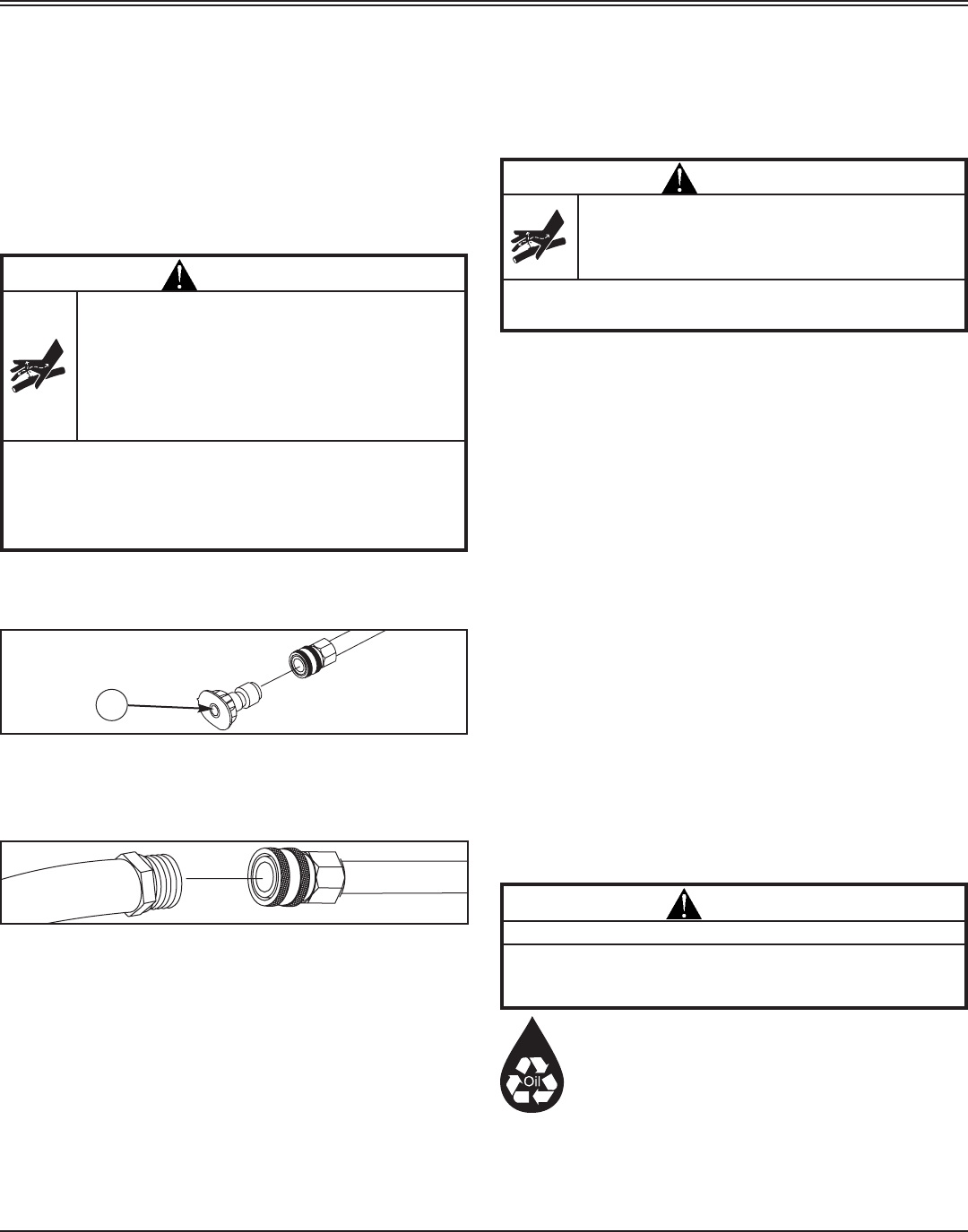

3. Remove spray tip from end of nozzle extension.

4. Use a small paper clip to free any foreign material clogging

or restricting spray tip (A).

5. Remove nozzle extension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush between

30 to 60 seconds.

7. Reinstall spray tip into nozzle extension.

8. Reconnect nozzle extension to spray gun.

9. Make sure garden hose is connected to water inlet. Check

that high pressure hose is connected to spray gun and

pump. Turn on water.

10. Start engine following instructions How to Start Your

Pressure Washer.

11. Test pressure washer by operating with each quick connect

spray tip.

O-Ring Maintenance

Purchase an O-Ring/Maintenance Kit, Model 6048, by contacting

the nearest authorized dealer. It is not included with the pressure

washer. This kit includes replacement o-rings, rubber washer and

water inlet filter. Refer to the instruction sheet provided in the kit

to service your unit’s o-rings.

Pump Oil Maintenance

Changing Pump Oil

Change oil after first 50 hours of operation and then every

200 hours or 3 months, whichever occurs first.

NOTE: When changing pump oil, use only high quality

nondetergent 30 weight oil. Use no special additives.

Change pump oil as follows:

1. Clean area around brass oil drain plug at bottom of pump.

2. Remove oil drain plug. Drain oil completely into an

approved container.

3. When oil has completely drained, install oil drain plug and

tighten firmly.

4. Clean area around pump oil dipstick. Remove dipstick and

fill pump with recommended oil (approximately 9.6 oz.) to

“Full” mark on dipstick.

5. Install pump oil dipstick.

6. Wipe up any spilled oil.

Engine Maintenance

See the engine operator’s manual for instructions on how to

properly maintain the engine.

KEEP OUT OF REACH OF CHILDREN. DON’T POLLUTE.

CONSERVE RESOURCES. RETURN USED OIL TO

COLLECTION CENTERS.

A

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

can cause injury.

• Keep high pressure hose connected to pump and spray gun while

system is pressurized.

• ALWAYS point spray gun in safe direction, press red button and

squeeze spray gun trigger, to release high pressure, every time you

stop engine.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

possible amputation.

• NEVER repair leaking connections with sealant of any kind. Replace

o-ring or seal.

CAUTION

Avoid prolonged or repeated skin contact with used motor oil.

• Used motor oil has been shown to cause skin cancer in certain

laboratory animals.

• Thoroughly wash exposed areas with soap and water.