a

60, 90 and 125 Skid-Steer Loaders

30-200-3

PRODUCT FEATURES

Compact and Maneuverable

John Deere skid-steer loaders are compact in design for

greater maneuverability in tight, close-quarter areas. They

will operate in areas in which the conventional, tractor-

mounted loadersare too largeto fit. Narrow and able to turn

within their ownradiuses, these machines are fully at home

inside calf pens, milking barns and poultry houses. Other

applications include:general contractors, foundries, fertiliz-

er plants, barge lines, nurseries and rental.

The little 60Loader isonly35-1/4 incheswide;the 90 is47

incheswide;and the Model 125is 59-1/2 inches wide.These

dimensions apply to those loaders equipped with standard-

equipment tires, and without buckets. For further informa-

tion on size, see "Specifications".

Another reason that these machines willprovide suchout-

standing maneuverability is their four-wheel drive features.

Left and right wheels operate independently of each other,

and can counter-rotate so that the loader can turn 360 de-

grees in its own track.

Engines

John Deere skid-steer loaders use engines that are de-

signed for the rugged, tough use to which skid-steer loaders

are subjected.

125 Skid-Steer Loader

The 125is availablewith a liquid-cooled gasolineor diesel

engine. Both engines are compact and smooth in operation.

The 125 gasoline engine develops 37 horsepower at 2800

rpm. The continental engine has earned its reputation in

forklift trucks and other heavy-duty, industrial-type equip-

ment. It provides a 21 percent torque rise.

The 125 Diesel engine develops 40 horsepower at 2800

rpm. The Isuzu Diesel has provided years of dependable

service for refrigeration units in semi-trailer trucks. John

Deerewasthe first to use Isuzu in a skid-steer loader. Today

it sets the standard for the industry.

90 Skid-Steer Loader

The 90 uses a proven, two-cylinder, 23-horsepower,gaso-

line engine.This engine is wellmatched for the sizeof the 90

and isdesignedto giveexcellent reliability throughout years

of service.

60 Skid-Steer Loader

The engine used in the 60 is a two-cylinder, 17-horsepow-

er, air-cooled,gasoline engine.

Hydrostatic Drive

All three models utilize hydrostatic drive, for immediate

response and increased productivity. The hydrostatic sys-

tem is totally independent of the hydraulic system. Hydro-

static drive also means less maintenance than for loaders

with variable drive systems. Hydrostatic drive eliminates

gear boxes, clutches, and variable drive belts, all high main-

tenance parts. This lower maintenance requirement will

help to increase productivity potential.

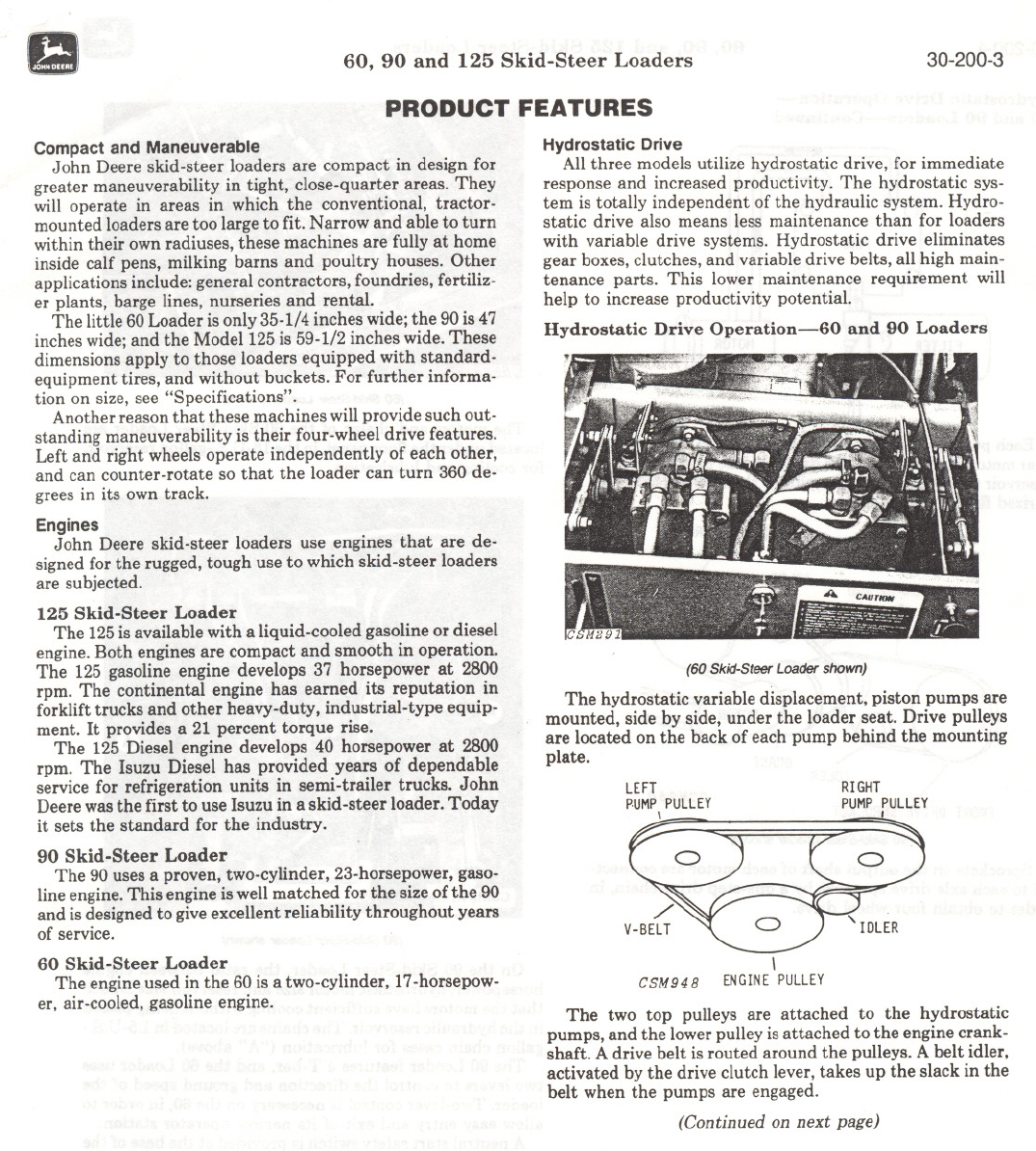

Hydrostatic Drive Operation-60 and 90 Loaders

(60 Skid-Steer Loader shown)

The hydrostatic variable displacement, piston pumps are

mounted, side by side, under the loader seat. Drive pulleys

are located on the back of each pump behind the mounting

plate.

LEFT

P.UMP PULLEY

,

RIGHT

PUMPPULLEY

CSM948

\

ENGINE PULLEY

The two top pulleys are attached to the hydrostatic

pumps, and the lower pulley is attached to the engine crank-

shaft. A drive belt is routed around the pulleys. A belt idler,

activated by the drive clutch lever, takes up the slack in the

belt when the pumps are engaged.

(Continued on next page)