12 601457_1107

trol levers are not in the park brake position (park brake switches are disen-

gaged) or the deck clutch switch is engaged the engine will stop.

The following steps are the correct procedures for starting the engine. If

difficulty is encountered, contact the Hustler Dealer in your area.

1. Before starting tractor each day, perform daily pre-operation checking.

(See Safety start interlock system section)

2. Make sure the steering control levers are in the park brake position and

deck clutch switch is disengaged. Only start the engine from the opera-

tor’s position.

3. Use choke, if unit is equipped with one, when engine is cold, or if warm

engine fails to start within 5 seconds of cranking. Avoid flooding and

operate engine without choking as soon as possible.

4. Set throttle at approximately 1/2 open position.

5. Insert key in ignition switch and rotate full clockwise to engage starting

motor. Release key when engine starts.

IMPORTANT: The engine starter should not be operated for periods

longer than 30 seconds at a time. An interval of at least two minutes should

be allowed between such cranking periods to protect the starter from over-

heating and burn-out.

6. Perform test to make sure safety start interlock system is operating prop-

erly. Refer to Safety start interlock system section.

7. As soon as engine begins to run, check to make certain the oil warning

light, engine light and alternator warning light (if applicable) are off. If

not, stop engine immediately and check for the cause.

8. Allow the engine to idle a few minutes before advancing the throttle and/

or engaging the deck clutch.

9. Before stopping the engine, place the steering control levers in the park

brake position, disengage the deck clutch, and throttle back to low idle

for a couple of minutes; then rotate ignition key counter-clockwise to the

OFF position. Remove the key from switch before leaving the tractor.

Stopping the engine

Use the following procedure to shut off the engine after operating the

equipment.

1. Place the steering control levers in the park brake position

2. Disengage the deck clutch

3. Throttle back to low idle for a couple of minutes

4. Rotate ignition key counter-clockwise to the OFF position. Remove the

key from switch before leaving the tractor.

Moving tractor with stalled engine

If it becomes necessary to move the tractor when the engine is inopera-

tive, the transaxles are equipped with bypass valves.

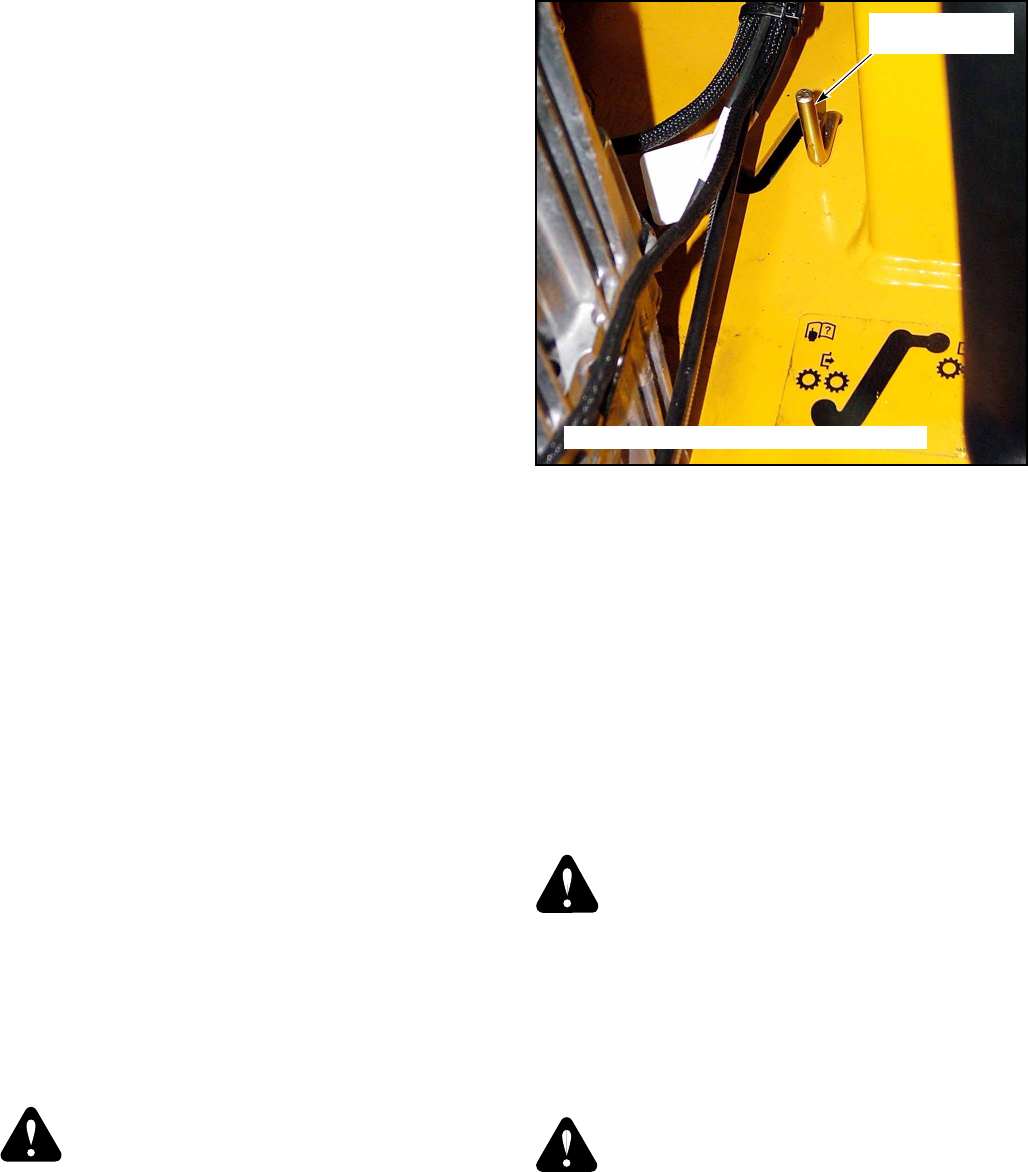

Before moving the unit, pull up on the bypass valve rod and slide it in the

slot to the disengaged position.

The steering control levers must be placed in the neutral position, to

release the park brakes, so that the tractor can be moved. Both bypass valve

rods are located at the front corners of the engine on the engine platform.

Fig. 3-5

Do not tow the machine. Move it by hand or use a winch to load on a

trailer for transporting.

When transporting on another vehicle, the tractor must be secured.

IMPORTANT: Always make certain the two bypass valves are returned

to their operating position before running the tractor following repairs.

WARNING: Allow engine exhaust manifold to cool before

engaging or disengaging the bypass valves. The bypass valve

rods are located close to the exhaust system.

ROPS

(Roll Over Protection Structure)

The two-post ROPS can be pivoted down so that the machine can oper-

ate under low hanging tree limbs or other obstructions. Do not wear the seat

belt when the ROPS is in the lowered position.

Always fasten seat belt during operation of the machine (mower

equipped with ROPS in “raised/up” position). Fig. 3-7

Inspect the area to be mowed for proper overhead clearance (tree limbs,

guide wires, doorways, etc)

Do not contact any overhead object with the ROPS.

Inspect the seat belt system (all seat, seat belt parts, seat pan and seat pan

latch) daily prior to mowing for signs of any damage. These parts should be

replaced if any parts indicate signs of:

1. cuts

2. fraying

3. extreme or unusual wear

4. significant discoloration due to UV exposure

5. dirt or stiffness

6. abrasion to the seat belt webbing

7. damage to the buckle, latch plate or hardware.

8. or any other problem

The ROPS structure’s protective capability may be impaired by struc-

tural damage, overturn or alteration. Do not remove or alter any of the

ROPS parts. Failure to adhere to these instructions could result in severe

injury or death.

WARNING: To minimize chance of injury or death from roll-

over: keep ROPS in the raised and locked position and use the

seat belt.

There is no roll over protection when the ROPS is in the lowered posi-

tion.

Lower the ROPS only when absolutely necessary. Drive slowly and

carefully. Raise the ROPS as soon as clearance permits. Read and follow

slope operation instructions and warnings.

Do not wear seat belt when the ROPS is in the lowered position.

Driving the tractor

DANGER: Never make sudden stops or reverse direction,

especially when maneuvering on a slope. The steering is

designed for sensitive response. Rapid movement of the steer-

ing control levers in either direction could result in a reaction

of the tractor that can cause serious injury.

After starting engine, engage the control levers and steer as follows:

To go forward, push steering control levers forward an equal distance

(Fig. 3-6).

To go in reverse, pull steering control levers rearward an equal distance

(Fig. 3-6).

To turn left, move the right steering control lever farther forward from

neutral than the left steering control lever.(Fig. 3-6)

To turn right, move the left steering control lever farther forward from

neutral than the right steering control lever. (Fig. 3-6)

Figure 3-5

Bypass valve rod shown in operating position

Bypass valve rod

(Right rod shown)