21

SERVICE AND ADJUSTMENTS

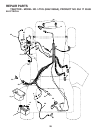

FIG. 21

ADJUSTMENT

BOLT

NEUTRAL

LOCK GATE

GEARSHIFT LEVER

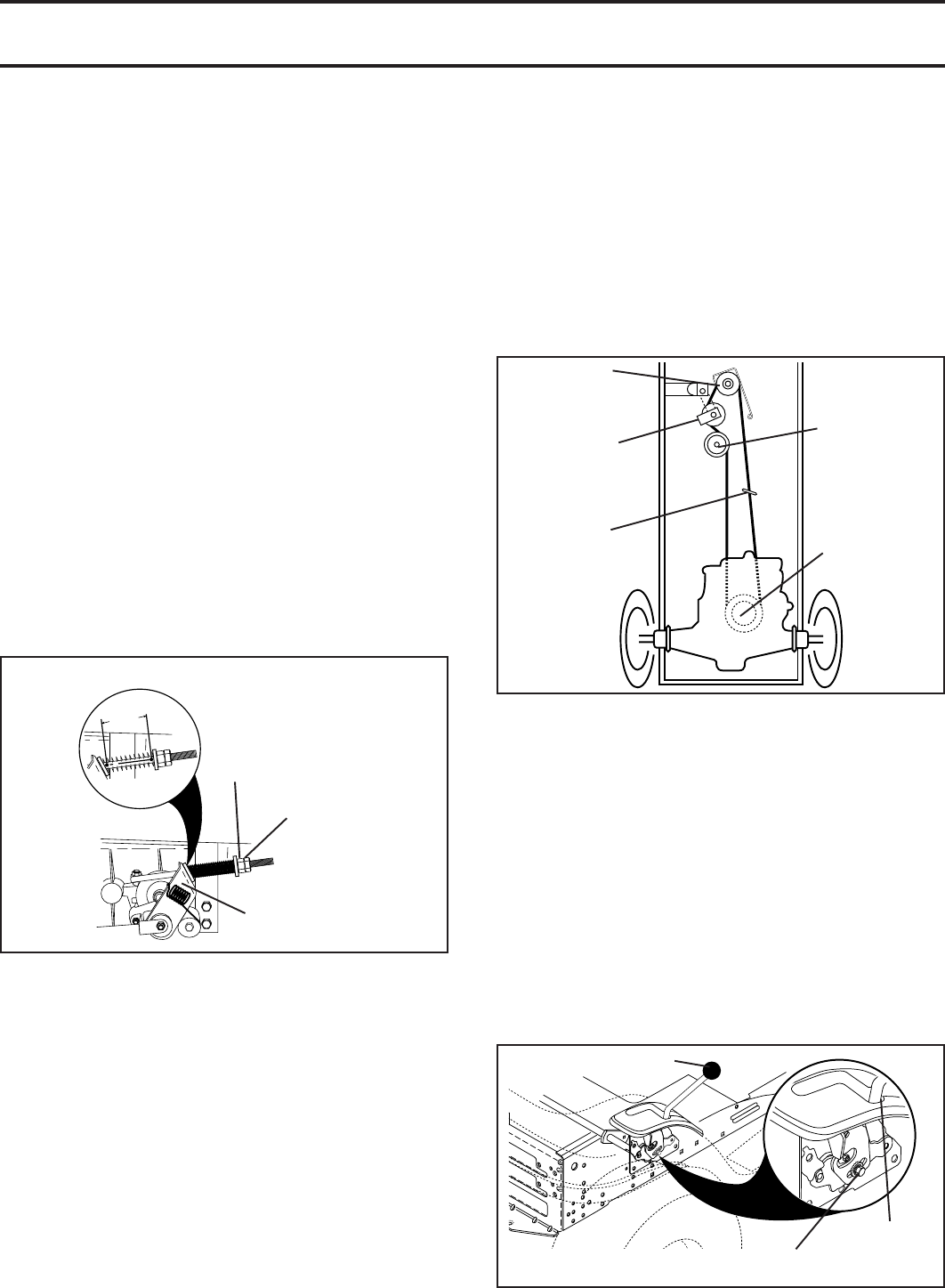

FIG. 23

TRANSAXLE GEAR SHIFT LEVER NEUTRAL

ADJUSTMENT (See Fig. 23)

The transaxle should be in neutral when the gear shift lever

is in neutral (N) (lock gate) position. The adjustment is preset

at the factory; however, if adjustment is needed, proceed as

follows:

• Make sure transaxle is in neutral (N).

NOTE: When the tractor rear wheels move freely, the

transaxle is in neutral.

• Loosen adjustment bolt in front of the right rear wheel.

• Position the gear shift lever in the neutral (N) position.

• Tighten adjustment bolt securely.

NOTE: If additional clearance is needed to get to adjustment

bolt, move mower deck height to the lowest position.

FIG. 22

TO REPLACE MOTION DRIVE BELT

(See Fig. 22)

Park the tractor on level surface. Engage parking brake. For

assistance, there is a belt installation guide decal on bottom

side of left footrest.

BELT REMOVAL -

• Remove mower (See “TO REMOVE MOWER” in this

section of manual).

NOTE: Observe entire motion drive belt and position of all

belt guides and keepers.

• Remove belt from stationary idler and clutching idler.

• Remove belt downward from around engine pulley.

• Pull belt slack toward rear of tractor. Remove belt

upwards from transaxle pulley by deflecting belt keep-

ers.

• Remove belt from center span keeper and pull belt away

from tractor.

BELT INSTALLATION -

• Carefully work new belt down between transaxle belt

keepers and onto the input pulley.

• Slide belt into the center span keeper.

• Pull belt toward front of tractor and roll around the top

groove of engine pulley.

• Install belt through stationary idler and clutching idler.

• Make sure belt is in all pulley grooves and inside all belt

guides and keepers.

• Install mower (See “TO INSTALL MOWER” in this

section of manual).

TRANSAXLE

PULLEY

STATIONARY

IDLER

CLUTCHING

IDLER

ENGINE

PULLEY

CENTER

SPAN

KEEPER

TO CHECK AND ADJUST BRAKE (See Fig. 21)

Your tractor is equipped with an adjustable brake system

which is mounted on the right side of the transaxle.

If tractor requires more than five (5) feet to stop at highest

speed in highest gear on a level, dry concrete or paved

surface, then brake must be checked and adjusted.

TO CHECK BRAKE

• Park tractor on a level, dry concrete or paved surface,

depress clutch/brake pedal all the way down and engage

parking brake.

• Place gear shift lever in neutral (N) position.

The rear wheels must lock and skid when you try to manually

push the tractor forward. If the rear wheels rotate, the brake

needs to be adjusted or the pads need to be replaced.

TO ADJUST BRAKE

• Depress clutch/brake pedal all the way down and en-

gage parking brake.

• Measure distance between brake operating arm and nut

“A” on brake rod.

• If distance is other than 1-1/2", loosen jam nut and turn

nut “A” until distance becomes 1-1/2". Retighten jam nut

against nut “A”.

• Road test tractor for proper stopping distance as stated

above. Readjust if necessary. If stopping distance is

still greater than five (5) feet in highest gear, further

maintenance is necessary. Replace brake pads or

contact a qualified service center.

1-1/2"

JAM NUT

WITH PARKING BRAKE “ENGAGED”

OPERATING ARM

NUT “A”