MACHINE´S SAFETY EQUIPMENT

English

–

7

General

This section describes the machine´s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

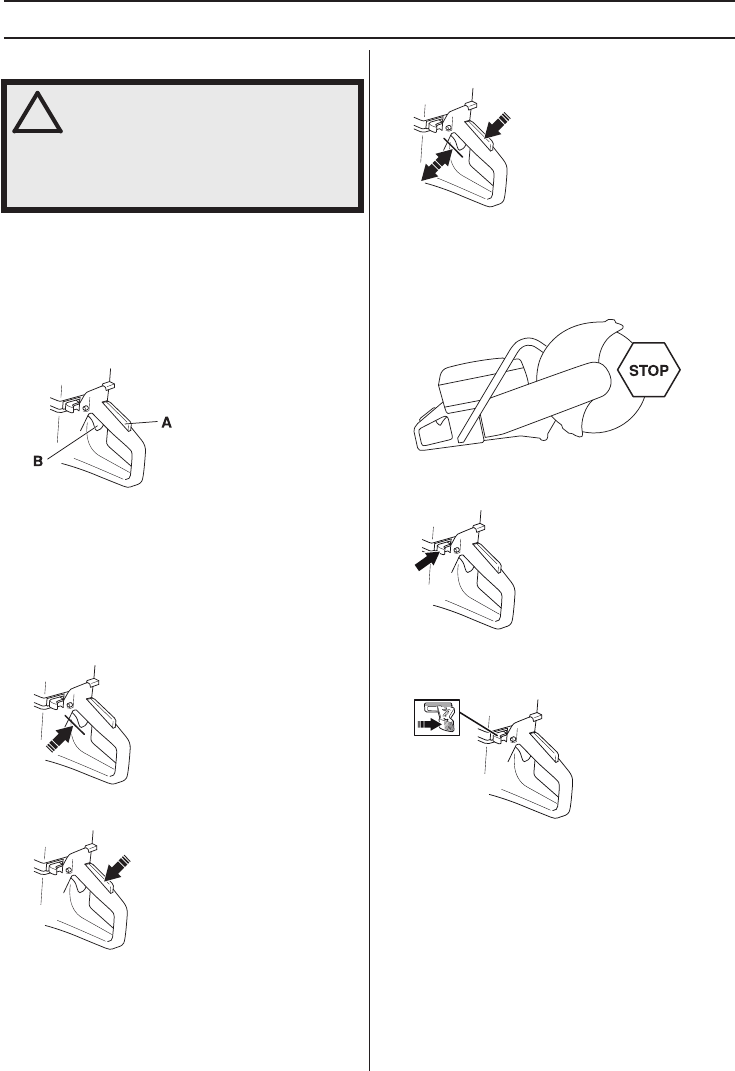

Throttle lockout

The throttle trigger lock is designed to prevent accidental

operation of the throttle. When the lock (A) is pressed in

this releases the throttle (B).

The trigger lock remains pressed in as long as the throttle

is pressed. When the grip on the handle is released the

throttle trigger and the throttle trigger lock both return to

their original positions. This is controlled by two

independent return spring systems. This means that the

throttle trigger is automatically locked in the idle position.

Checking the throttle lockout

• Make sure the throttle control is locked at the idle

setting when the throttle lockout is released.

• Press the throttle lockout and make sure it returns to

its original position when you release it.

• Check that the throttle trigger and throttle lockout

move freely and that the return springs work properly.

• Start the power cutter and apply full throttle. Release

the throttle control and check that the cutting blade

stops and remains stationary. If the cutting blade

rotates when the throttle is in the idle position you

should check the carburettor’s idle adjustment. See

instructions in the section "Maintenance".

Stop switch

Use the stop switch to switch off the engine.

Checking the stop switch

• Start the engine and make sure the engine stops

when you move the stop switch to the stop setting.

!

WARNING! Never use a machine that has

faulty safety equipment! If your machine

fails any checks contact your service

agent to get it repaired.

The engine should be switched off, and

the stop switch in STOP position.