23

SERVICE AND ADJUSTMENTS

TRANSMISSION REMOVAL/REPLACEMENT

Should your transmission require removal for service or

replacement, it should be purged after reinstallation and

before operating the tractor. See “PURGE TRANSMIS-

SION” in the Operation section of this manual.

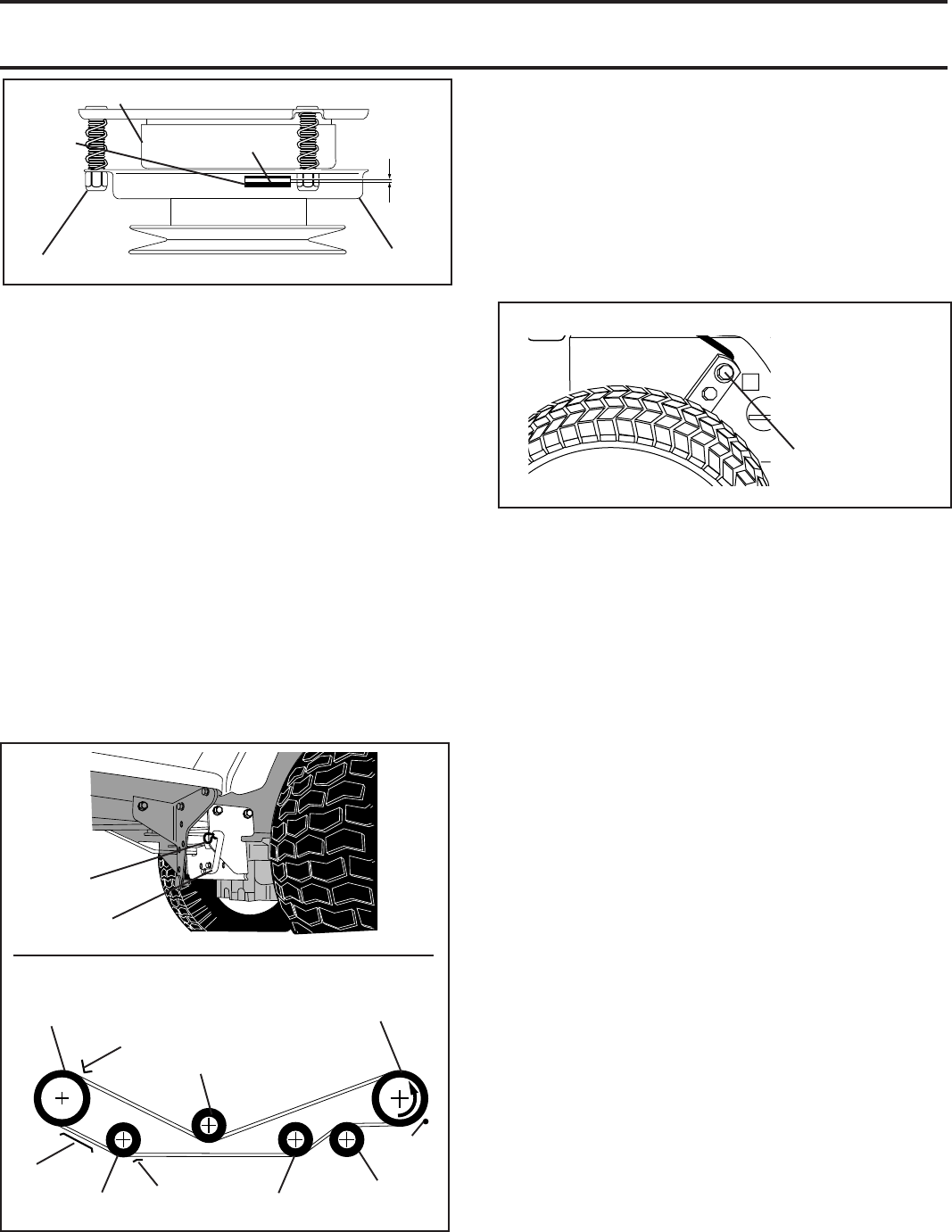

FIG. 26

ENGINE PULLEY

RETAINER

SPRING

DRIVE BELT

TENSION HANDLE

BELT KEEPER

BELT

KEEPER

V-IDLER

CLUTCHING

IDLER

CLUTCHING

FLAT IDLER

BELT

KEEPER

FLAT IDLER

TRANSAXLE

PULLEY

TRANSAXLE MOTION CONTROL LEVER

NEUTRAL ADJUSTMENT (See Fig. 27)

The motion control lever has been preset at the factory and

adjustment should not be necessary.

• Park tractor on level surface. Stop tractor by turning

ignition key to “OFF” position and engage parking brake.

• Loosen the adjustment bolt in front of the right rear

wheel.

• Move motion control lever to the neutral position (N).

• Tighten the adjustment bolt.

FIG. 27

ADJUSTMENT

BOLT

TO ADJUST STEERING WHEEL ALIGNMENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straight forward, remove steer-

ing wheel and reassemble with crossbars horizontal. Tighten

securely.

FRONT WHEEL TOE-IN ADJUSTMENT

Front wheel toe-in is required for proper steering operation.

Toe-in was set at the factory and adjustment should not be

necessary. If parts in the front axle or steering mechanism

have been replaced or damaged, check toe-in and adjust if

necessary.

TO CHECK TOE-IN (See Fig. 28)

• Position front wheels straight ahead.

• Measure distance between wheels at front and rear of

tires (dimensions “A” and “B”).

• Front dimension “A” should be 1/8" to 1/4" less than rear

dimension “B”.

TO ADJUST TOE-IN (See Figs. 28 and 29))

• Loosen jam nuts at adjustment sleeves on tie rod.

• Adjust tie rod until dimension “A” is 1/8" to 1/4" less than

dimension “B”.

• Tighten jam nuts securely.

BELT INSTALLATION -

• Install new belt around engine pulley first, then around

transaxle pulley and lastly into all the idler pulleys.

• Check to be sure belt is positioned correctly and is on

proper side of all belt keepers.

• Engage the drive belt tension handle and replace the

retainer spring.

• Reinstall mower.

NYLON LOCKNUT (3)

BRAKE PLATE

SLOT (3)

ROTOR

CLUTCH PLATE

.012"

FIG. 25

TO REPLACE MOTION DRIVE BELT

(See Fig. 26)

Park the tractor on level surface. Engage parking brake. For

ease of service there is a belt installation guide decal on

bottom of left footrest.

• Remove mower (See “TO REMOVE MOWER” in this

section of this manual.)

BELT REMOVAL -

• Create slack in belt by removing retainer spring from

drive belt tension handle.

• Remove belt from all idler pulleys, transaxle pulley and

then from engine pulley.

BELT

KEEPER