Hose clamps are not completely tight.

Please tighten hose clamps prior to using.

Hose clamps are left loose to extend life

of gaskets and ttings.

Oil cap gasket before using and

lubricate weekly so the gasket will seal

properly and prevent chemical leaks.

Oil check valve and keep breather

hole clear of debris. Your failure to oil

may cause the tank to collapse

and crack due to vacuum created by

pump lubricate with “3 and 1” oil.

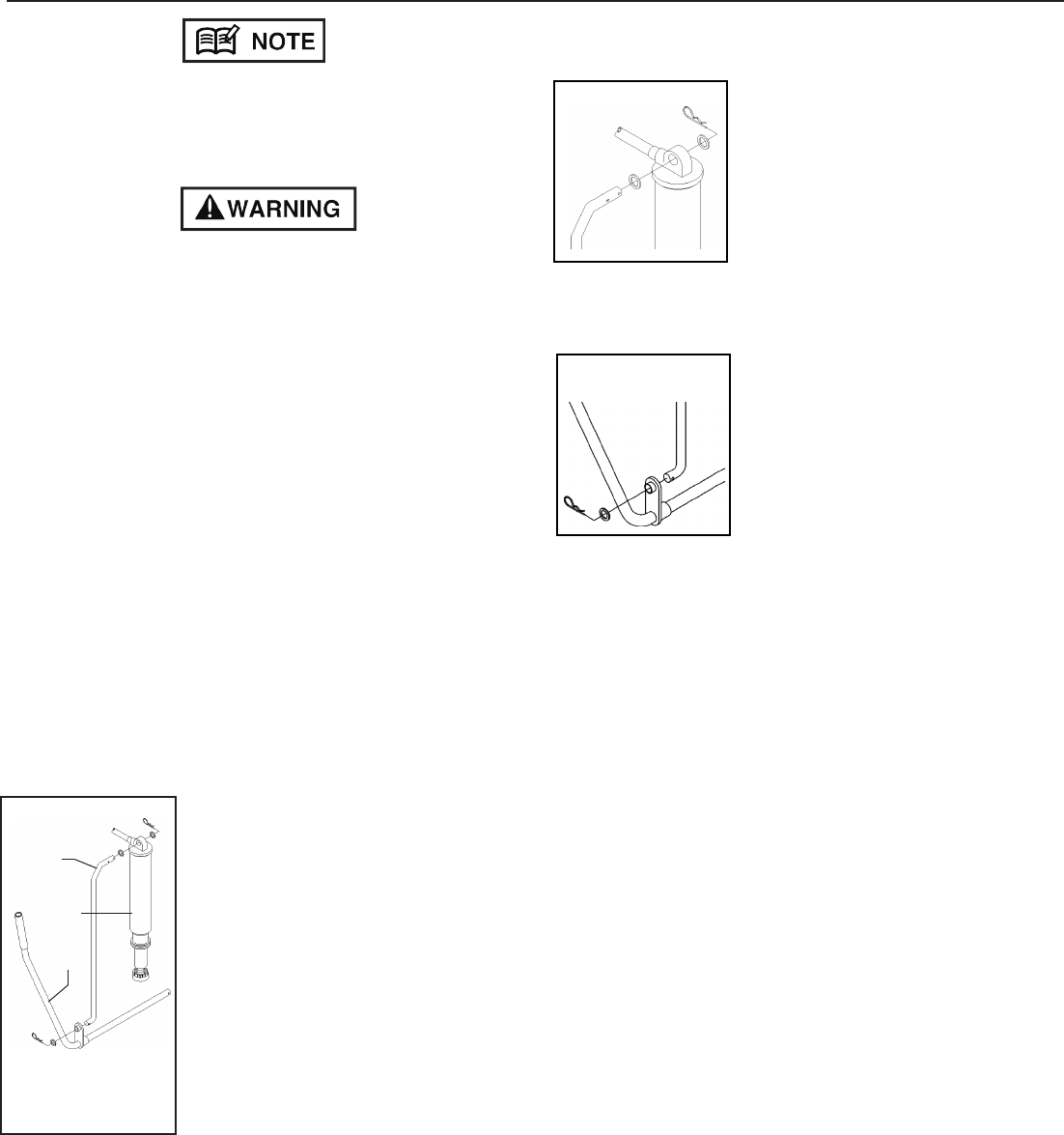

ASSEMBLY OF PUMP HANDLE PUMP

LEVER & PUMP MODULE

Pull sprayer, pump lever, pump handle,

spray wand, plastic bag (with washers

and pins), etc. out of box. Place parts in

front of you. Take the pump lever, there

are bends on either side. (See gure 2).

Place one Washer through the bar, then

push lever through opening on pump,

place washer on pump lever and then

place hairpin lock and push through.

On the same side where the pump is

located, place the round portion of the

pump handle through the hole on the

base of the sprayer. When it is almost

through, place the bent portion of the

pump lever through the hole on the at

portion of the handle. Once through, place

on one washer and, then the locking pin.

(See gure 3). The round tube comes

through the base of the unit and extends

out 6.4mm (1/4”), exposing the hole

drilled through the tube. Place on the

other washer and the other holding pin.

The pump handle assembly is now

complete.

HIP SUPPORT

Take the black plastic hip portion and side

the two end sections into the two

receiving notches on the base, the

rounded side up.

STRAPS

Hook the plastic clip attached to the

shoulder straps into the appropriate

lateral opening on the hip support.

SPRAY WAND AND NOZZLE

Attach spray wand to spray gun and rmly

tighten. To adjust nozzle, tighten (turn

clockwise), cap for a ne atomized spray,

or loosen (turn counter clockwise), for a

coarser spray or solid stream.

THE SPRAYER IS NOW READY TO

USE.

5. Set up

■ HOW TO ASSEMBLE

Included in the box, please nd the

following:

1) PUMP HANDLE & PUMP LEVER.

2) SPRAYER (Pump Module installed).

3) HIP SUPPORT. (Packed in tank)

4) SPARE PARTS (bag with locking pins

& washer).

5) AGITATOR (Packed in tank)

PUMP HANDLE

The pump handle is made of a tubular

steel with a plastic grip on one end, and a

round tube welded to the opposite side at

right angle. The at bar has a hole

12.5mm (1/2”) in diameter. This hole is

located 57mm (2 1/4”) from the round

tube. (See gure 1).

PUMP LEVER

The pump lever is made of a 15.2cm

(1/2’) solid round steel bar with two

bends, one on either side of the bar. (See

gure 1).

PUMP MODULE

Pump module is installed in the sprayer.

Now proceed to install pump handle and

lever.

Fig. 2

Fig. 1

Fig. 3

BP5

US-6

(2)

(3)

(1)

(1) Pump Handle

(2) Pump Lever

(3) Pump Module