9

SETUP AND ADJUSTMENTS

Mower Deck Leveling

Position machine on a flat surface. Preferably

level concrete.

Check the tire pressure in all four tires. Inflation

should be 15 psi.

Place 2x4’s on edge under the cutting deck from

front to rear and lower the deck down onto

2x4’s.

Adjust the four upper chain bolts to the center

slots in the deck lift arms. NOTE: Make sure the

lift blocks under the frame are tightly bolted to

the frame.

Check the chains for equal tension. If unequal

adjust upper chain bolt in slot.

Place the deck in the 5” cutting height and

measure from the cutting edge of the blade to

the flat level surface to check the deck cutting

height.

Throttle Lever Tension

Stop engine and remove key.

Throttle lever tension may be adjusted by

tightening the pivot bolt. The pivot bolt secures

the throttle arm to the mounting bracket which is

mounted to the console. Access is gained by

removing the console.

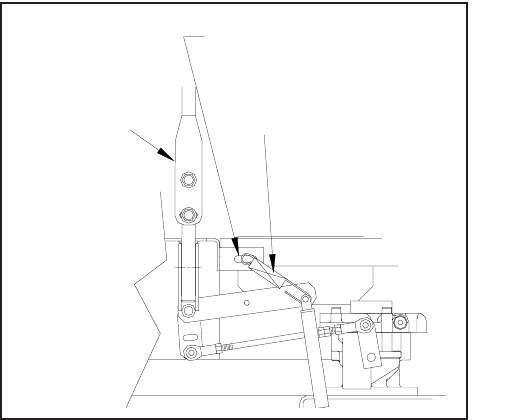

Reverse Spring Detent Adjustment

Stop engine and remove key.

Pull the motion control lever back to the reverse

position and release the lever. When the lever

stops it should be in line with the neutral slot, so

you can move the lever into neutral slot with out

hitting the side of the console frame.

If adjustment is required put the seat in the rear

most position on the slide, tilt the seat forward,

remove the seat rod from seat frame and fold

seat over forward onto the frame.

On the back of the console where the spring is

fastened, loosen the 3/8” nut and bolt enough to

allow the bolt to slide in the slot. FIG - 6

Motion

Control

Lever

Reverse Detent

Adjustment Slot

Reverse Detent

Spring

Rotate the motion control lever out into the

neutral slot. While the lever is swung out into

the neutral slot pull it against the the back edge

of the neutral slot. Holding the lever adjust the

spring by sliding the bolt in the slot to remove

all the slop and retighten the bolt.

Check your adjustment by repeating the sec-

ond step in this process.

If no more adjustment is needed reassemble

the seat rod to the seat frame.

FIG - 6