24

MAINTENANCE

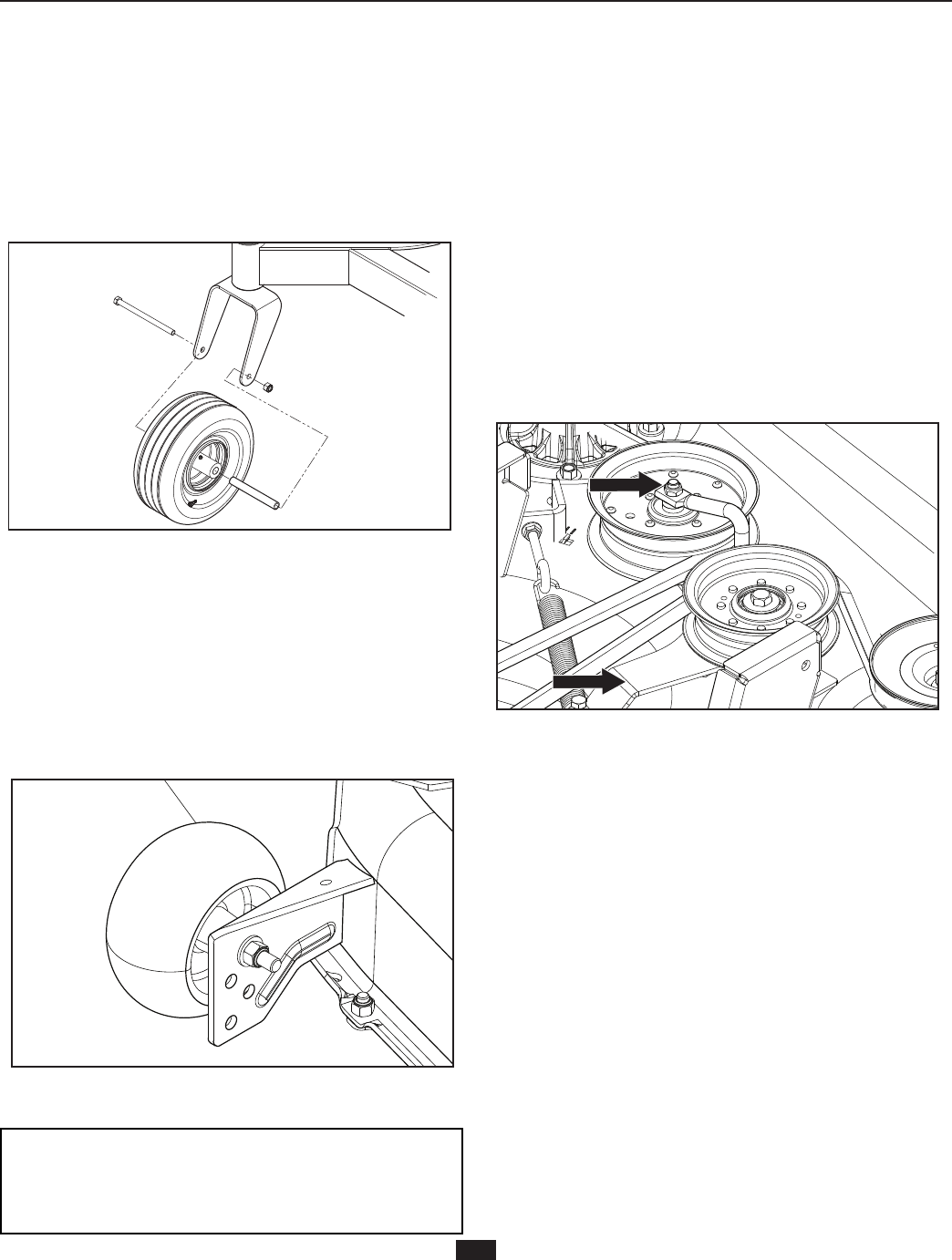

Caster Wheels

Check every 200 hours. Check that wheels rotate freely. If

wheels do not rotate freely take the unit to your dealer for

service.

Foam filled tires or solid tires will void the warranty.

Removal and installation

Remove nut and caster bolt. Pull the wheel out of the yoke and

take care of the spacers. Install in reverse order. Tighten caster

bolt.

IMPORTANT INFORMATION Adjust anti-scalp rollers with

the mower on a flat level surface.

To avoid deck damage, the anti-scalp rollers must not be

adjusted to support the deck.

Anti-scalp Rollers

Anti-scalp rollers are properly adjusted when they are just

slightly off of the ground when the deck is at the desired

cutting height in the operating position. Anti-scalp rollers then

keep the deck in the proper position to help prevent scalping

in most terrain conditions.

Anti-scalp rollers can be set in four positions. The rollers

should be approximately ¼" (6.5 mm) from the ground. Do not

adjust the rollers to support the deck.

V-belts

Check every 100 hours of operation. Check for severe

cracking and large nicks.

NOTE: The belt will show some small cracks in normal

operation.

The belts are not adjustable. Replace belts if they begin to slip

from wear.

Deck Belt Removal

1. Park on a level surface. Apply park brake.

2. Lower the deck into the lowest cutting position.

3. Remove bolts from belt shields and remove shields.

4. Remove any dirt or grass that may have accumulated

around the cutter housings and entire deck surface.

5. Loosen the nut securing the belt guide. Note the position

of the belt guide for reinstallation.

6. Push inward on the idler arm to release the tension on the

belt.

7. Carefully lift the belt over the top of the cutter housing

pulleys and remove belt from the deck.

Deck Belt Installation

NOTE: For ease in installing the deck belt, refer to the

routing decal on the top of the deck.

1. Wrap the deck belt around the electric clutch pulley

located on the engine shaft.

2. Route the belt forward and up onto the deck.

3. Place belt around spring loaded idler pulley.

4. Wrap the belt around the stationary idler pulley and

around the mandrel housings.

5. Push inward on the idler arm and carefully route belt over

stationary idler pulley. Once the belt is properly routed,

slowly release the idler arm to tension belt.

6. Double check belt routing to make sure it matches the

decal affixed to the deck, and the belt does not have any

twist. Correct if needed.

7. Tighten the belt guide and replace belt shields on both

mandrel housings and secure with fasteners.

NOTE: The belt guide should be perpendicular to the belt

when installation is complete.