10

LAWN MOWER

Always observe safety rules when performing main te nance.

TIRES

• Keep tires free of gasoline, oil, or insect control chem-

i cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

BLADE CARE

For best results, mower blade must be kept sharp. Re place

bent or dam aged blades.

CAUTION: Use only a replacement blade

approved by the manufacturer of your

mower. Using a blade not approved

by the manufacturer of your mower is

hazardous, could damage your mower

and void your warranty.

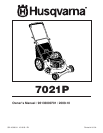

TO REMOVE BLADE (See Fig. 10)

1. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

2. Turn lawn mower on its side. Make sure air fi lter and

carburetor are up.

3. Use a wood block between blade and mower hous ing

to prevent blade from turning when re mov ing blade bolt.

NOTE: Protect your hands with gloves and/or wrap blade

with heavy cloth.

4. Remove blade bolt by turning counter-clockwise.

5. Remove blade and attaching hardware (bolt, lock wash er

and hardened wash er).

NOTE: Remove the blade adapter and check the key inside

hub of blade adapter. The key must be in good condition to

work properly. Replace adapter if dam aged.

TO REPLACE BLADE (See Fig. 10)

1. Position the blade adapter on the engine crank shaft.

Be sure key in adapter and crankshaft key way are

aligned.

2. Position the blade on the blade adapter aligning the

two (2) holes in the blade with the raised lugs on the

adapter.

3. Be sure the trailing edge of blade (opposite sharp edge)

is up toward the engine.

4. Install the blade bolt with the lock washer and hard ened

washer into blade adapter and crank shaft.

5. Use block of wood between blade and lawn mower

housing and tighten the blade bolt, turning clock wise.

• The recommended tightening torque is 35-40 ft. lbs.

IMPORTANT: BLADE BOLT IS HEAT TREATED. IF BOLT NEEDS

REPLACING, REPLACE ONLY WITH APPROVED BOLT SHOWN

IN THE REPAIR PARTS SECTION OF THIS MANUAL.

TO SHARPEN BLADE

NOTE: We do not recommend sharp en ing blade - but if you

do, be sure the blade is balanced. An un bal anced blade

will cause eventual damage to lawn mower or engine.

• The blade can be sharp ened with a fi le or on a grinding

wheel. Do not attempt to sharpen while on the mower.

MAINTENANCE

FIG. 10

BLADE

BOLT

HARDENED

WASHER

LOCK

WASHER

BLADE ADAPTER

KEY

BLADE

TRAILING EDGE

CRANKSHAFT

KEY WAY

CRANKSHAFT

• To check blade balance, drive a nail into a beam or

wall. Leave about one inch of the straight nail ex posed.

Place center hole of blade over the head of the nail.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

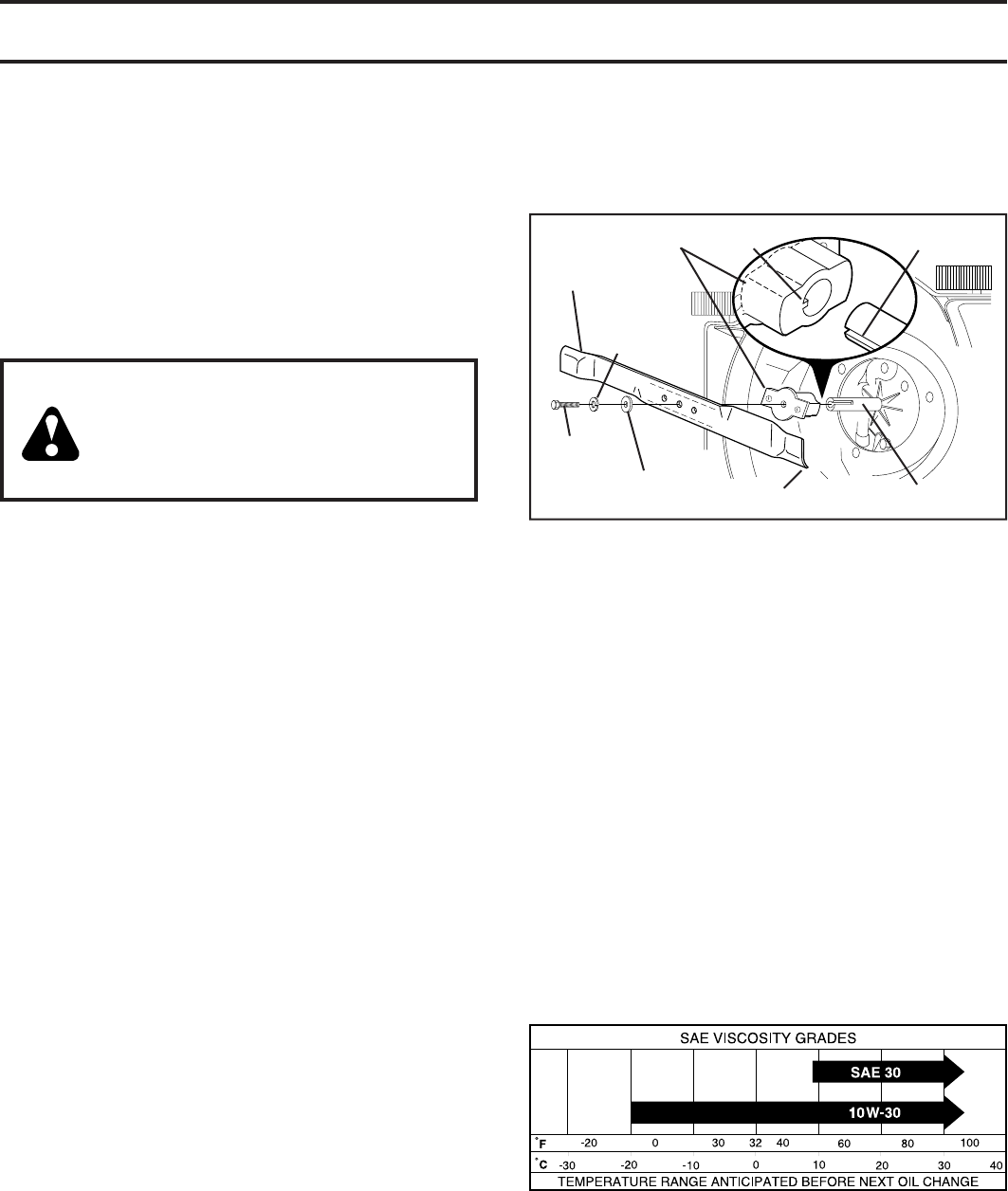

NOTE: Multi-viscosity oils (5W30, 10W30 etc.) improve

starting in cold weather, and you should check your engine

oil level frequently to avoid possible engine damage from

running low on oil.

Change the oil after every 25 hours of operation or at least once

a year if the lawn mower is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each fi ve (5) hours of continuous use. Tighten oil

plug securely each time you check the oil level.

GRASS CATCHER

• The grass catcher may be hosed with water, but must

be dry when used.

• Check your grass catcher often for damage or de te -

ri o ra tion. Through normal use it will wear. If catcher

needs replacing, replace only with ap proved replace-

ment catcher shown in the Repair Parts section of this

manual. Give the mower model number when ordering.

ENGINE

Maintenance, re pair, or re place ment of the emission con-

trol de vic es and sys tems, which are be ing done at the

cus tom ers expense, may be performed by any non-road

engine repair es tab lish ment or individual. Warranty repairs

must be performed by an authorized engine man u fac tur er's

service outlet.

LUBRICATION

Use only high quality detergent oil rated with API service

classifi cation SF-SJ. Select the oil's SAE viscosity grade

according to your expected operating temperature.