MAINTENANCE

English – 29

General

The user must only carry out the maintenance and

service work described in this Operator’s Manual. More

extensive work must be carried out by an authorized

service workshop.

Carburettor adjustment

Your Husqvarna product has been designed and

manufactured to specifications that reduce harmful

emissions.

AutoTune

If the engine is equipped with AutoTune, manual

adjustment of the carburettor’s H and L needles and the T-

screw no longer applies. Both needles and the T-screw

have been removed. AutoTune is a function that adjusts

the carburettor electronically, always resulting in optimal

adjustment.

Function

• The carburettor controls the speed of the engine via

the throttle. Air/fuel is mixed in the carburettor. This air/

fuel mixture is adjustable.

• The automatic adjustment of the carburettor means

that the engine is adapted to local conditions, e.g. the

climate, altitude, petrol and the type of 2-stroke oil.

This function is controlled by AutoTune.

Engine adjustment

The following steps should be taken when the chain saw

is started for the first time or when outside circumstances

change (fuel, altitude, air filter etc.): Start the engine.

Accelerate the engine to full throttle and saw a number of

cuts in a thick log (3-5 min.).

The chain saw must be run (8,000 - 12,000 rpm) the entire

time so that the carburettor can adjust itself.

Conditions

NOTE! The ignition system includes an in-built speed

limiter. When the speed governor is activated, you will get

the same sound experience as when the chain saw 4-

cycles.

Checking, maintaining and

servicing chain saw safety

equipment

Chain brake and front hand guard

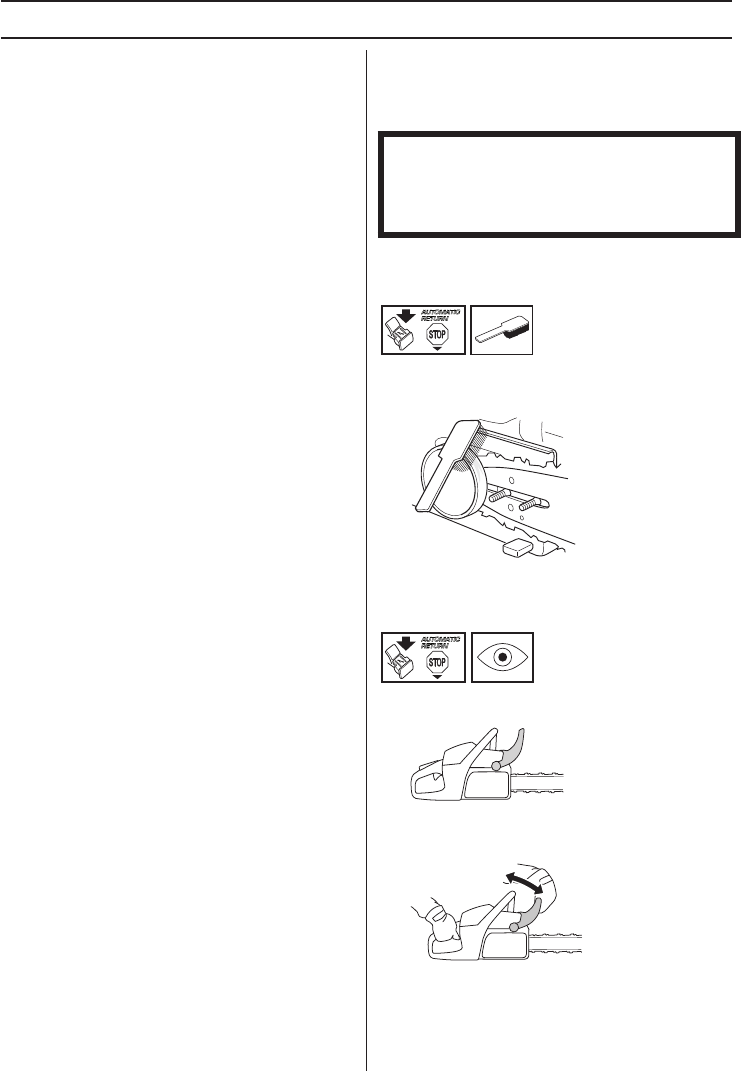

Checking brake band wear

Brush off any wood dust, resin and dirt from the chain

brake and clutch drum. Dirt and wear can impair operation

of the brake.

Regularly check that the brake band is at least 0,6 mm

thick at its thinnest point.

Checking the front hand guard

Make sure the front hand guard is not damaged and that

there are no visible defects such as cracks.

Move the front hand guard forwards and back to make

sure it moves freely and that it is securely anchored to the

clutch cover.

Note! All service and repair work on the machine

demands special training. This is especially true of the

machine’s safety equipment. If your machine fails any of

the checks described below we recommend that you

take it to your service workshop.