WORKING TECHNIQUES

English – 23

Working methods

• Before you start clearing, check the clearing area, the

type of terrain, the slope of the ground, whether there

are stones, hollows etc.

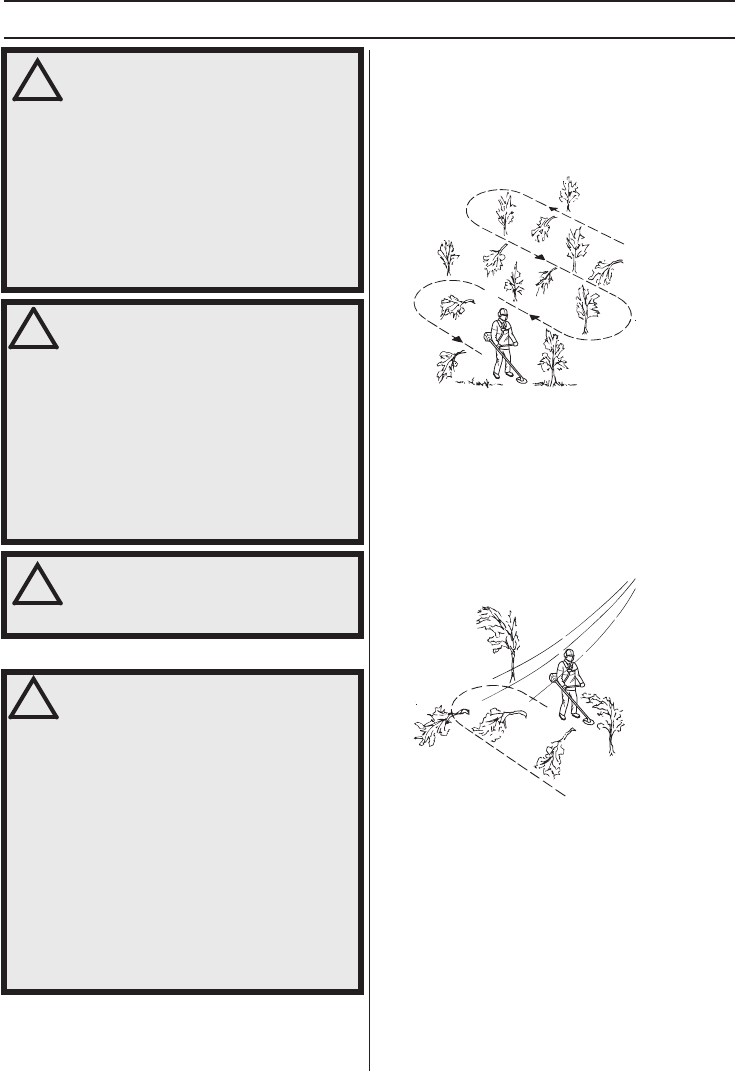

• Start at whichever end of the area is easiest, and clear

an open space from which to work.

• Work systematically to and fro across the area,

clearing a width of around 4-5 m on each pass. This

exploits the full reach of the machine in both directions

and gives the operator a convenient and varied

working area to work in.

• Clear a strip around 75 m long. Move your fuel can as

work progresses.

• On sloping ground you should work along the slope. It

is much easier to work along a slope than it is to work

up and down it.

• You should plan the strip so that you avoid going over

ditches or other obstacles on the ground. You should

also orient the strip to take advantage of wind

conditions, so that cleared stems fall in the cleared

area of the stand.

!

WARNING! Neither the operator of the

machine nor anyone else may attempt to

remove the cut material while the engine

is running or the cutting equipment is

rotating, as this can result in serious

injury.

Stop the engine and cutting equipment

before you remove material that has

wound around the blade shaft as

otherwise there is a risk of injury. The

bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

!

WARNING! Watch out for thrown objects.

Always wear approved eye protection.

Never lean over the cutting attachment

guard. Stones, rubbish, etc. can be thrown

up into the eyes causing blindness or

serious injury.

Keep unauthorised persons at a distance.

Children, animals, onlookers and helpers

should be kept outside the safety zone of

15 m. Stop the machine immediately if

anyone approaches. Never swing the

machine around without first checking

behind you to make sure no-one is within

the safety zone.

!

WARNING! Sometimes branches or

grass get caught between the guard and

cutting attachment. Always stop the

engine before cleaning.

!

WARNING! Machines fitted with saw

blades or grass blades can be thrown

violently to the side when the blade comes

into contact with a fixed object. This is

called blade thrust. A blade thrust can be

violent enough to cause the machine and/

or operator to be propelled in any

direction, and possibly lose control of the

machine. Blade thrust can occur without

warning if the machine snags, stalls or

binds. Blade thrust is more likely to occur

in areas where it is difficult to see the

material being cut.

Avoid cutting with the area of the blade

between the 12 o’clock and 3 o’clock

positions. Because of the speed of

rotation of the blade, blade thrust can

occur if you attempt to cut thick stems

with this area of the blade.