English – 13

SAFETY INSTRUCTIONS

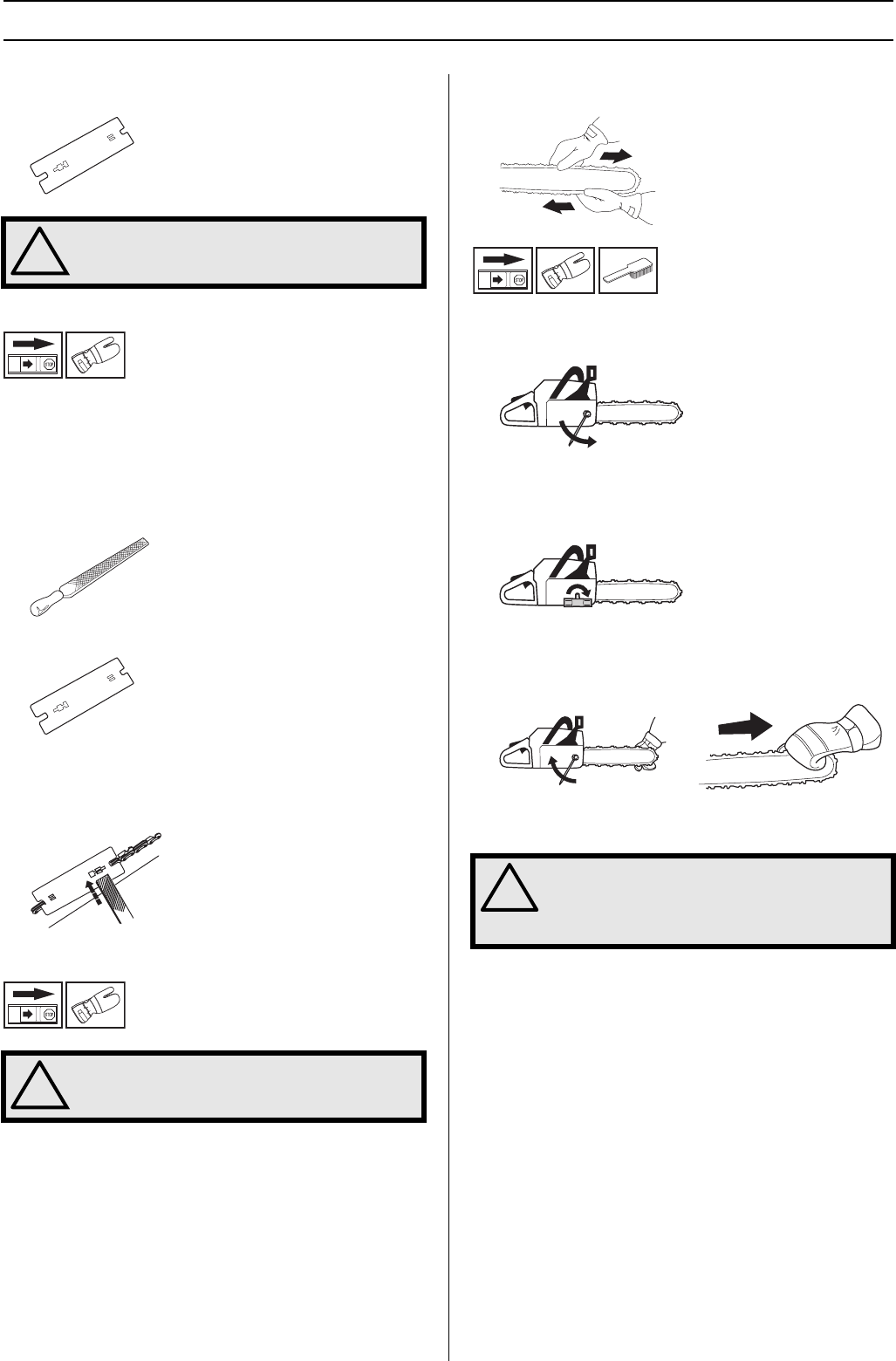

• We recommend that you use our raker gauge to achieve

the correct clearance and bevel on the raker lip.

Setting the raker clearance

• Before setting the raker clearance the cutting teeth should

be newly sharpened. We recommend that you adjust the

raker clearance every third time you sharpen the chain.

NOTE! This recommendation assumes that the length of

the cutting teeth is not reduced excessively.

• To adjust the raker clearance you will need a flat file and a

raker gauge.

• Place the gauge over the raker lip.

• Place the file over the part of the lip that protrudes through

the gauge and file off the excess. The clearance is correct

when you no longer feel any resistance as you draw the

file over the gauge.

Tensioning the chain

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up the

slack.

Check the chain tension every time you refuel. NOTE! A new

chain has a running-in period during which you should check

the tension more frequently.

The position of the chain tensioning screw on our chain saws

varies from model to model. See the What is what? section to

find out where it is on your model.

Tension the chain as tightly as possible, but not so tight that

you cannot pull it round freely by hand.

• Loosen the bar nuts that hold the clutch cover/chain

brake. Use the combination spanner. Then tighten the bar

nuts by hand as tight as you can.

• Raise the tip of the bar and stretch the chain by tightening

the chain tensioning screw using the combination

spanner. Tighten the chain until it does not sag from the

underside of the bar.

• Use the combination spanner to tighten the bar nuts while

lifting the tip of the bar at the same time. Check that you

can pull the chain round freely by hand and that it does not

sag from the underside of the bar.

Lubricating cutting equipment

Chain oil

Chain oil must demonstrate good adhesion to the chain and

also maintain its flow characteristics regardless of whether it

is warm summer or cold winter weather.

As a chain saw manufacturer we have developed an optimal

chain oil which has a vegetable oil base. We recommend the

use of our own oil for both maximum chain life and to minimise

environmental damage. If our own chain oil is not available,

standard chain oil is recommended.

In areas where oil specifically for lubrication of saw chains is

unavailable, ordinary EP 90 transmission oil may be used.

Never use waste oil! This is dangerous for yourself, the

machine and the environment.

!

WARNING! The risk of kickback is increased

if the raker clearance is too large!

!

WARNING! A slack chain may jump off the

bar and cause serious or even fatal injury.

!

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

which could lead to serious, even fatal

injuries.