30 – English

Starter device

WARNING!

• When the recoil spring is assembled in the starter

housing, it is in tensioned position and can when

treated carelessly, pop out and cause injuries.

• Always be careful, when changing the recoil spring or

the starter cord. Always wear safety goggles for eye

protection.

MAINTENANCE

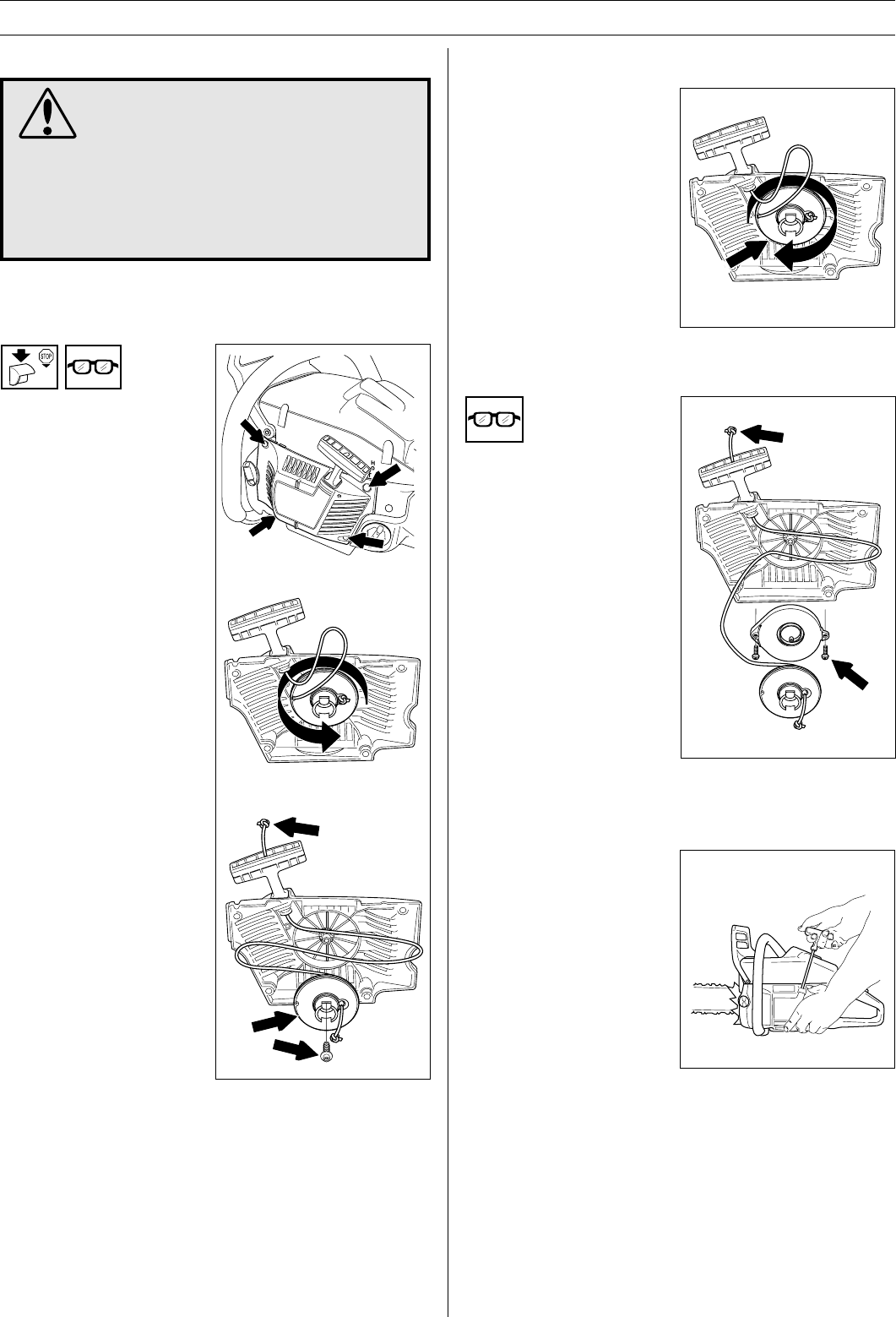

Changing a broken or worn

starter cord

• Loosen the screws, that

hold the starter device

against the crankcase and

remove the starter device.

• Pull out the cord approx. 30

cm and lift it up into the

notch in the pulley. Zero-set

the recoil spring by letting

the pulley rotate slowly

backwards. Undo the screw

in the centre of the pulley

and remove the pulley.

• Insert and fasten a new

starter cord in the pulley.

Wind approx. 3 turns of the

starter cord on to the pulley.

Assemble the starter pulley

against the recoil spring, so

the end of the spring

engages to the pulley. Fit

the screw in the centre of

the pulley. Carry the starter

cord through the hole in the

starter housing and the

starter handle. Make a knot

on the starter cord.

Tensioning the recoil spring

• Lift the starter cord up in the

notch on the starter pulley

and turn the starter pulley 2

turns clockwise.

NOTE! Check that the

starter pulley can be turned

at least half a turn, when the

starter cord is entirely pulled

out.

Starter device assembly

• Assemble the starter

device, by pulling the starter

cord out first, then place the

starter against the

crankcase. Then slowly

release the starter cord so

that the pulley engages with

the pawls.

• Assemble and tighten the

screws, which hold the

starter.

Changing the broken recoil spring

• Lift the starter pulley (see

"Changing a broken or worn

starter cord"

). Bear in mind

that the return spring sits

under tension in a cassette.

• Dismantle the cassette with

the return spring from the

starter.

• Lubricate the recoil spring

with thin oil. Assemble the

cassette with return spring

in the starter. Fit the starter

pulley and tension the return

spring.