GENERAL SAFETY PRECAUTIONS

English – 13

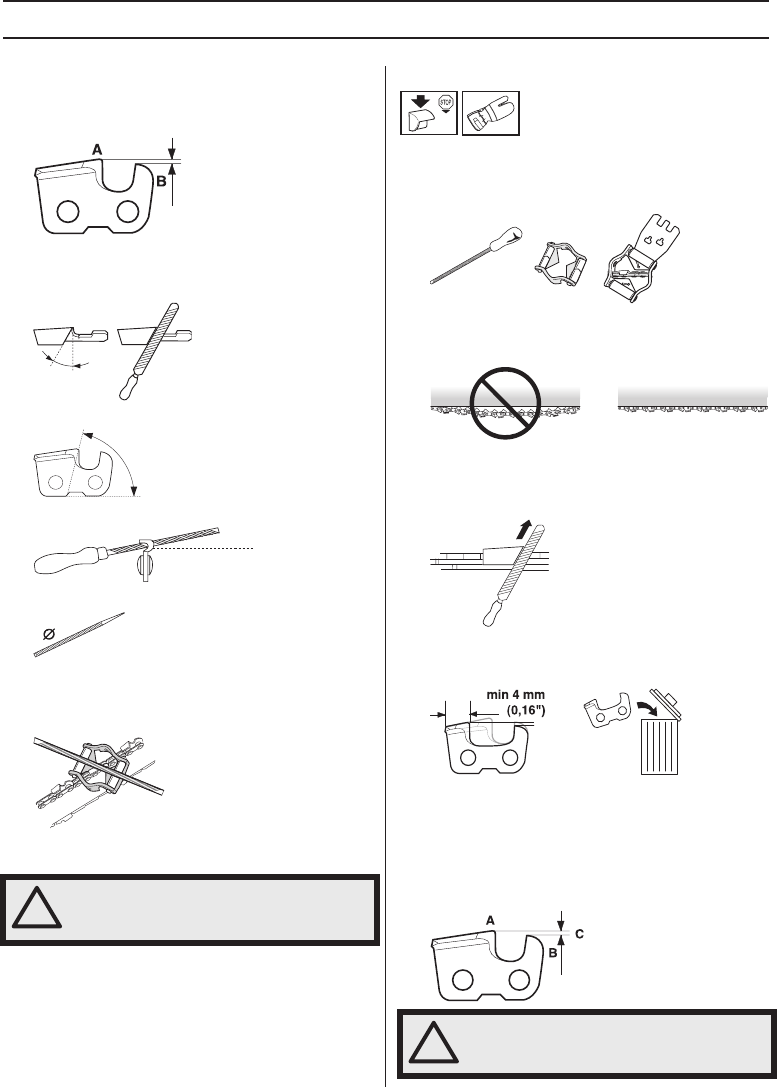

• The cutting part of the chain is called the cutter and

consists of a cutting tooth (A) and the depth gauge (B).

The cutters cutting depth is determined by the difference

in height between the two (depth gauge setting).

When you sharpen a cutting tooth there are four important

f

actors to remember.

1 Filing angle

2 Cutting angle

3 File position

4 Round file diameter

It is very difficult to sharpen a chain correctly without the right

equipment.

We recommend that you use our file gauge. This

will help you obtain the maximum kickback reduction and

cutting performance from your chain.

See instructions under the heading Technical data for

inf

or

mation about sharpening your chain.

Sharpening cutting teeth

To sharpen cutting teeth you will need a round file and a file

gauge. See instructions under the heading Technical data for

information on the size of file and gauge that are

recommended for the chain fitted to your chain saw.

• Check that the chain is correctly tensioned. A slack chain

will mo

v

e sideways, making it more difficult to sharpen

correctly.

• Always file cutting teeth from the inside face. Reduce the

pressure on the retur

n stroke. File all the teeth on one

side first, then turn the chain saw and file the teeth on the

other side.

• File all the teeth to the same length. When the length of

the cutting teeth is reduced to 0.16 inch (4 mm) the chain

is w

or

n out and should be replaced.

General advice on adjusting depth gauge setting

• When you sharpen the cutting tooth (A) the depth gauge

setting (C) will decrease. To maintain optimal cutting

performance the depth gauge (B) has to be filed down to

achieve the recommended depth gauge setting. See

instructions under the heading Technical data to find the

correct depth gauge setting for your particular chain.

!

WARNING! Departure from the sharpening

instructions considerably increases the

risk of kickback.

!

WARNING! The risk of kickback is increased

if the depth gauge setting is too large!