English – 29

MAINTENANCE

Conditions

• Before any adjustments are made the air filter should be clean

and the cylinder cowling fitted. Adjusting the carburettor while a

dirty air filter is in use will result in a leaner mixture when the filter

is finally cleaned. This can give rise to serious engine damage.

• Carefully turn the L and H-jets clockwise to the bottom. Now turn

the jets one turn anti-clockwise. The carburettor is now set to H =

1 and L = 1.

• Now start the saw according to the starting instructions and run it

warm for 10 minutes.

NOTE! If the chain rotates the T screw should be turned anti-

clockwise until the chain stops.

• Place the saw on a flat surface so that the bar points away from

you and so that the bar and chain do not come into contact with

the surface or other objects.

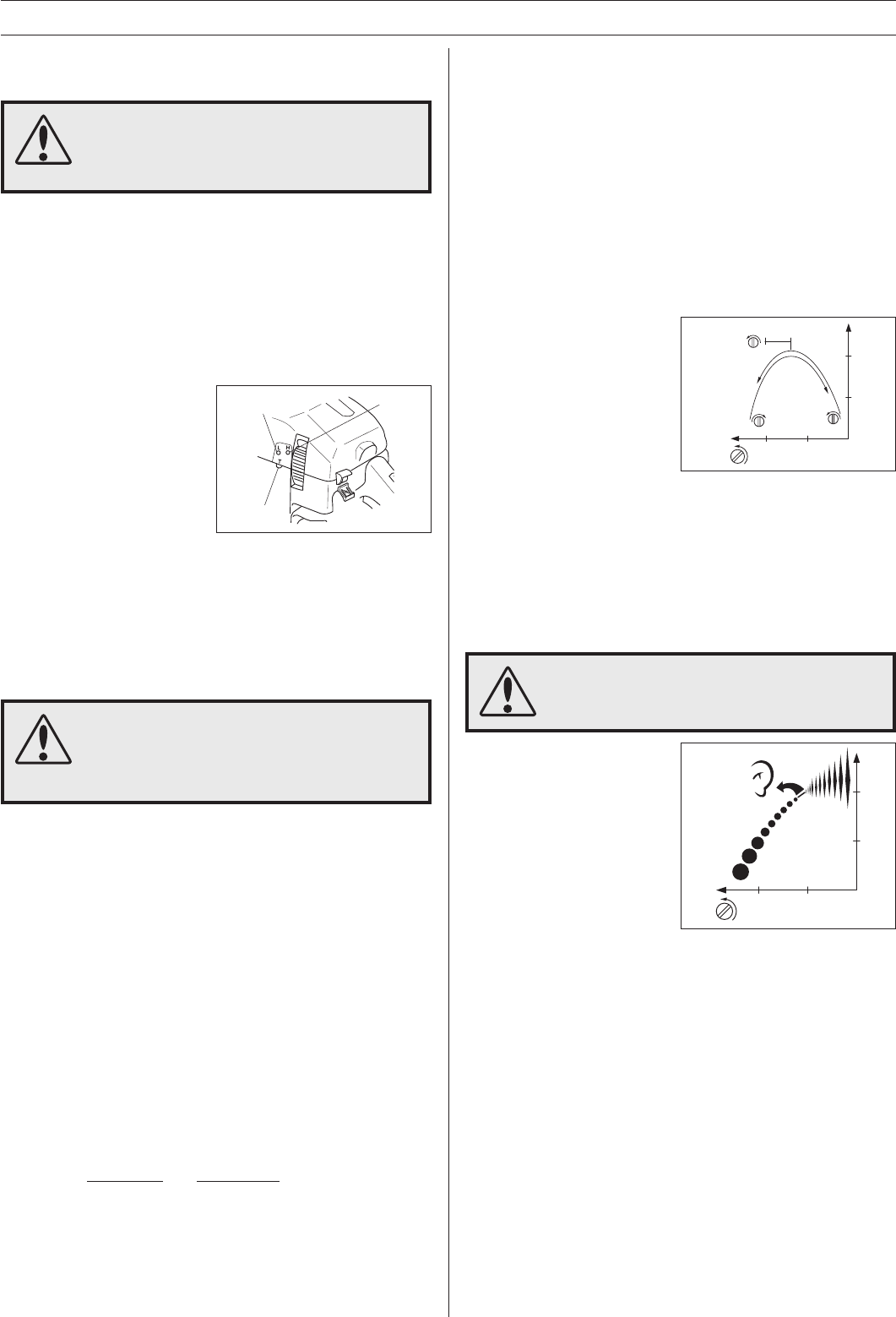

Low speed needle L

Try to find the highest idling

speed, turning the low speed

needle L clockwise respectively

counter-clockwise. When the

highest speed has been found,

turn the low speed needle L 1/4

turn counter-clockwise.

NOTE! If the chain rotates in

the idling position, turn the idling speed screw counter-

clockwise until the chain stops.

Final setting of the idling speed T

Adjust the idling speed with the screw T. If it is necessary to re-

adjust, first turn the idle speed adjusting screw T clockwise, until the

chain starts to rotate. Then turn, counter-clockwise until the chain

stops. A correctly adjusted idle speed setting occurs when the

engine runs smoothly in every position. It should also be good

margin to the rpm when the chain starts to rotate.

Contact your servicing dealer, if the idle speed

setting cannot be adjusted so that the chain

stops. Do not use the saw until it has been

properly adjusted or repaired.

High speed needle H

The high speed needle H

influences the power of the saw.

A too lean adjusted high speed

needle H (high speed needle H

closed too much) gives overrevs

and damages the engine. Let

the saw run at full speed for

about 10 seconds. Thereafter,

turn the high speed needle H 1/

4 turn counter-clockwise.

Let the saw run again at full speed for about 10 seconds and note

the difference of the enginesound. Repeat this procedure with the

high speed needle H turned 1/4 turn more counter-clockwise. The

saw has now been tested with the following settings: H=±0, H=+1/4,

H=+1/2 from basic adjustment. At full speed the engine has

produced a different sound for each setting. The high speed needle

H is correctly set when the saw ”4-cycles” a little. If the saw ”whist-

les” the setting is too lean. If there is too much exhaust gas at the

same time as the saw ”4-cycles” much, the setting is too rich. Turn

the high speed needle H until the setting sounds correct.

NOTE! For optimum setting of the carburettor, contact a qualified

servicing dealer who has a revolution counter at his disposal. The

maximum speed recommended must not be exceeded.

Correctly adjusted carburettor

A correctly adjusted carburettor means that the saw accelerates

without hesitation and the saw 4-cycles a little at max speed.

Furthermore, the chain must not rotate at idling. A too lean adjusted

low speed needle L may cause starting difficulties and bad accelera-

tion. A too lean adjusted high speed needle H gives lower

power=less capacity, bad acceleration and/or damage to the engine.

A too rich adjustment of the two speed needles L and H gives

acceleration problems or too low working speed.

L

+ 1/4

H

H

L

T

Carburettor

Functioning, Basic setting, Final setting

WARNING! Do not start the saw without the bar,

chain and clutch cover (chain brake) assembled.

If you do, the clutch might come loose and cause

severe injuries.

Operation

• The carburettor governs the engine speed via the throttle. Air/fuel are

mixed in the carburettor. The air/fuel mixture is adjustable. To take

advantage of the saw’s maximum output the setting must be correct.

• The satisfactory operation of a catalytic converter depends,

among other factors, on the correct adjustment of the

carburettor. Follow carefully the instructions below, using a

tachometer to check engine speed.

• Adjusting the carburettor means the engine is adapted to local

operating conditions, e.g. climate, altitude, petrol and the type of

2-stroke oil used.

• The carburettor has three

adjustment possibilities:

L = Low speed jet.

H = High speed jet.

T = Adjustment screw for

idling.

• The fuel quantity required in relation to the air flow, provided by

opening the throttle, is adjusted by the L and H-jets. If they are

screwed clockwise the air/fuel ratio becomes leaner (less fuel) and

if they are turned anti-clockwise the ratio becomes richer (more

fuel). A leaner mixture gives a higher engine speed and a richer

mixture give a lower engine speed.

• The T screw regulates the idling speed. If the screw T is turned

clockwise this gives a higher idling speed; anti-clockwise a lower

idling speed.

WARNING! The catalytic converter muffler gets

very hot during and after use. This also applies

during idling. Be aware of the fire hazard,

especially when handling the saw near flammable

substances or vapours.

Basic setting and running in

The carburettor is adjusted to a basic setting when the saw is tested at

the factory. The basic setting is: H = 1 turn respective L = 1 turn.

To provide the engine’s components with a good level of

lubrication (running in) the carburettor should be set for a

richer fuel mixture for the first 3-4 hours of operating. To obtain

this adjust the speed 6-700 rpm under the recommended max.

speed.

If you do not have the possibility to check the speed using a

tachometer the H-jet should not be set for a leaner mixture than that

stated for the basic setting.

The recommended speed should not be exceeded.

NOTE! If the chain rotates while idling the T screw should be

adjusted anti-clockwise until it stops.

Fine adjustment

• When the saw has been ”run-in” the carburettor should be finely

adjusted. The fine adjustment should be carried out by

qualified person. First adjust the L-jet, then the idling screw T

and then the H-jet. The following engine speed applies:

Max. speed Idling speed

345: 12 500 rpm 2 700 rpm

346XP: 14 200 rpm 2 700 rpm

353: 13 000 rpm 2 700 rpm

Changing the type of fuel

Fine tuning may be required if the chain saw, after changing the type

of fuel, performs differently with regard to starting, acceleration, max.

speed, etc.