English – 29

MAINTENANCE

Air filter

The air filter must be regularly cleaned to remove dust and dirt

in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts

• Excessive fuel consumption.

Clean the filter every 25 hours, or more regularly if conditions

are exceptionally dusty.

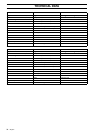

Cleaning the air filter

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water.

An oiled foam plastic filter (available as an accessory) must

be used if the machine is operated in extremely dusty

conditions. See instructions under the heading Oiling the air

filter.

Oiling the air filter

Always use HUSQVARNA filter oil, art. no. 531 00 92-48. The

filter oil contains a solvent to make it spread evenly through

the filter. You should therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour off

the excess before fitting the filter to the machine. Never use

common engine oil. This would drain through the filter quite

quickly and collect in the bottom.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced with

a new one at regular intervals. A damaged air filter must

always be replaced.

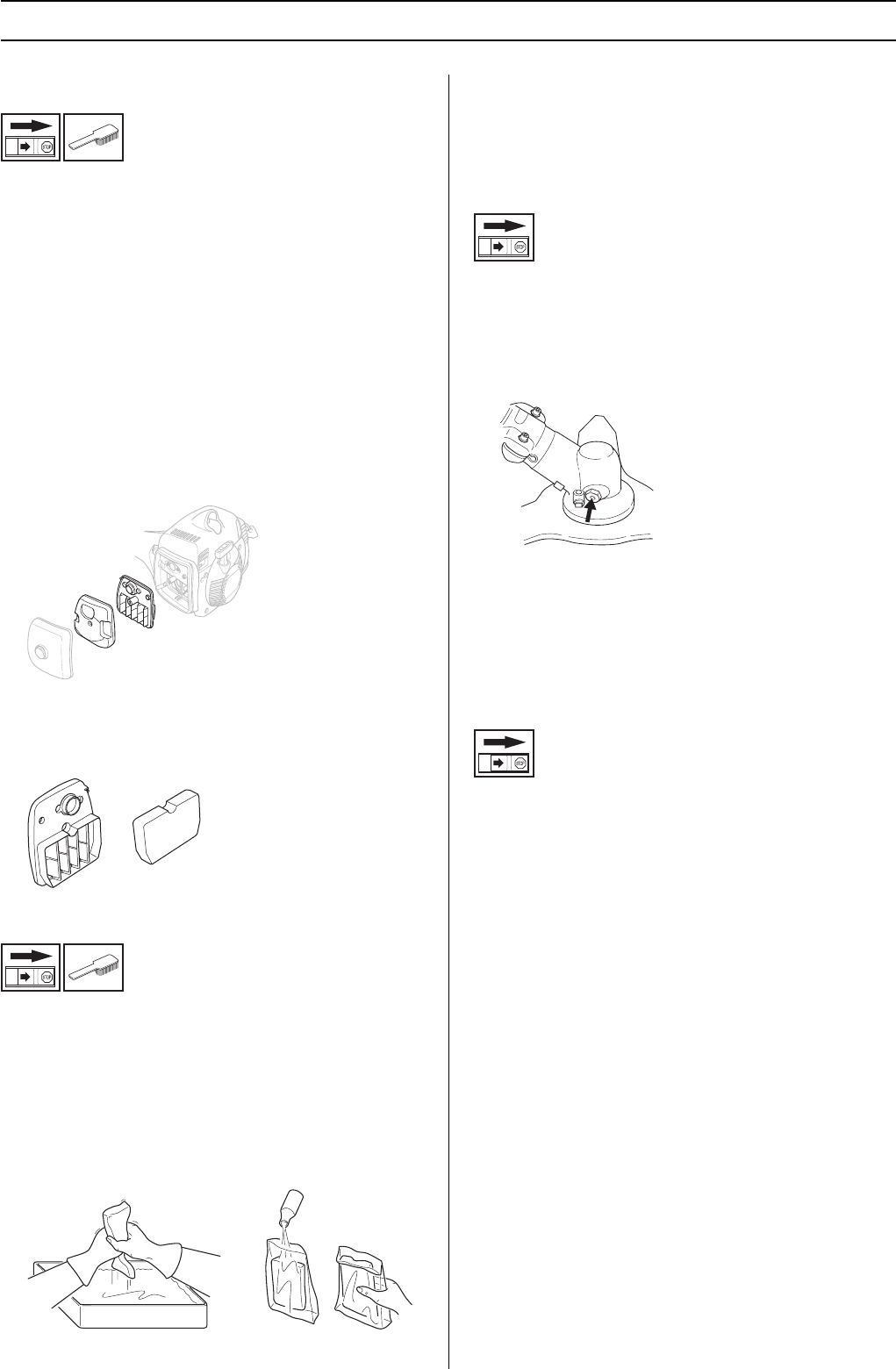

Bevel gear

The bevel gear is filled with the right quantity of grease at the

factory. However, before using the machine you should check

that the bevel gear is filled three-quarters full with grease. Use

HUSQVARNA special grease.

The grease in the bevel gear does not normally need to be

changed except if repairs are carried out.

Drive shaft

The drive shaft must be greased every three months during

full-time use. Contact your dealer if you are uncertain about

the procedure.

Spark plug

The spark plug condition is influenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or incorrect type of

oil).

• A dirty air filter.

These factors cause deposits on the spark plug electrodes,

which may result in operating problems and starting

difficulties.

If the machine is low on power, difficult to start or runs poorly

at idle speed: always check the spark plug first before taking

any further action. If the spark plug is dirty, clean it and check

that the electrode gap is 0.5 mm (0,020"). The spark plug

should be replaced after about a month in operation or earlier

if necessary.

CAUTION! Always use the recommended spark plug type!

Use of the wrong spark plug can damage the piston/cylinder.

Check that the spark plug is fitted with a suppressor.