English

– 7

SAFETY INSTRUCTIONS

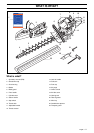

Muffler

• Never use a machine that has a faulty muffler.

• Regularly check that the muffler is securely attached to

the machine.

• If the muffler on your machine is fitted with a spark

arrestor mesh this must be cleaned regularly. A blocked

mesh will cause the engine to overheat and may lead to

serious damage. Never use a muffler with a defective

spark arrestor mesh.

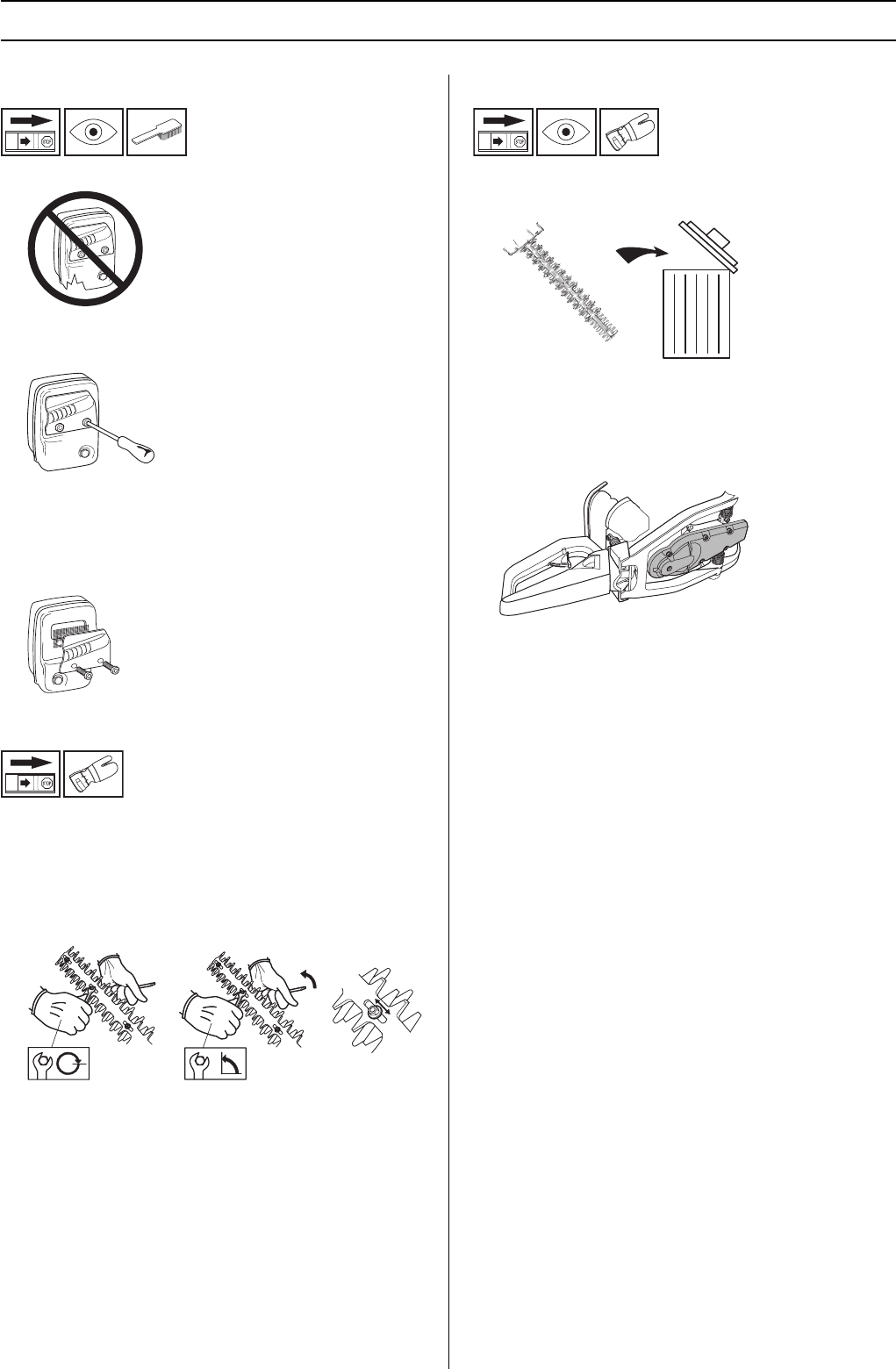

Blades

To ensure good cutting results it is important that the contact

pressure between the blades is correct. The contact pressure

is adjusted by turning the screws on the underside of the bar

clockwise as far as they will go. Then turn the screws

anticlockwise a 1/4 turn. Lock the screws using the locking nut

on the top of the bar. Check that the screws are loose enough

to allow the washers under the screw heads to slide sideways.

When the blades are correctly adjusted the play between the

blades should be 0,2–0,4 mm, measured at the screws.

The edges of the blades are too hard to be filed. Dull blades

should be sharpened using a grinder. Replace the blades if

they are bent or damaged.

Blade guard

• Check that the blade guard is not damaged or distorted.

• Replace the blade guard if it is bent or damaged.

Gear housing

• The gear housing gets hot when the machine has been in

use. To avoid burning yourself do not touch the gear

housing.