16 – English

Basic setting

• The carburetor is set to its basic setting when test run at the

factory. The basic setting should be kept during the machineʻs

fi rst working hours. Thereafter the carburetor should be fi nely

adjusted. Fine adjustment should be carried out by a skilled

technician.

NOTE! If the cutting attachment rotates/moves while the engine

is idling the T-screw should be turned anti-clockwise until the

cutting attachment stops.

Rec. idling speed: 2700 rpm.

Recommended max. speed: See ”Technical data”.

MAINTENANCE

Carburetor

Your Husqvarna product has been designed and manufactured

to specifi cations that reduce harmful emissions.

After your unit has been run 8-10 tanks of fuel the engine has

broken in. To ensure that your unit is at peak performance and

producing the least amount of harmful emissions after break

in, have your authorized servicing dealer, who has a revolution

counter at his disposal, to adjust your carburetor for optimum

operating conditions.

WARNING!

The complete clutch cover with shaft must

be fi tted before the machine is started, oth-

erwise the clutch can become loose and

cause personal injury.

!

Operation

• The carburetor governs

the engineʻs speed via the

throttle. Air/fuel is mixed in

the carburetor. The air/fuel

mixture is adjustable. To take

advantage of the engineʻs

optimal output the adjustment

must be correct.

• The setting of the carbure-

tor means that the engine is

adapted to local conditions,

for example, the climate, alti-

tude, gasoline and the type of

2-stroke oil.

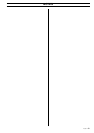

• The carburetor is equipped

with three adjustment pos-

sibilities:

L = Low speed needle

H = High speed needle

T = Idle speed adjuster

screw

• The fuel quantity in relation to

the air fl ow permitted by the

throttle opening is adjusted

using the L and H-needles.

Turning the needles clock-

wise gives a leaner fuel

mixture (less fuel) and turning

them anti-clockwise gives a richer fuel mixture (more fuel). A

leaner mixture gives high revs while a richer mixture give less

revs.

• The T-screw regulates the position of the throttle while the

engine is idling. Turning the screw clockwise gives a higher

idling speed while turning it anti-clockwise gives a lower idling

speed.

WARNING!

If the idling speed cannot be adjusted so

that the cutting attachment stops, contact

your service workshop. Do not use the

machine until it has been correctly adjusted

or repaired.

!

Fine adjustment

• When the machine has been ”run-in” the carburetor should

be fi nely adjusted. The fi ne adjustment should be carried

out by qualifi ed person. First adjust the L-jet, then the idling

screw T and then the H-jet.

Conditions

• Before any adjustments are made the airfi lter should be clean

and the airfi lter cover fi tted. Adjusting the carburetor while a

dirty airfi lter is in use will result in a leaner mixture when the

fi lter is fi nally cleaned. This can give rise to serious engine

damage.

• Carefully turn the L and H needle to the mid point between

fully turned in and fully turned out.

• Do not attempt to adjust the needles beyond the stops as

damage can occur.

• Now start the machine according to the starting instructions

and run it warm for 10 minutes.

NOTE! If the cutting attachment rotates/moves the T screw

should be turned anti-clockwise until the cutting attachment

stops.

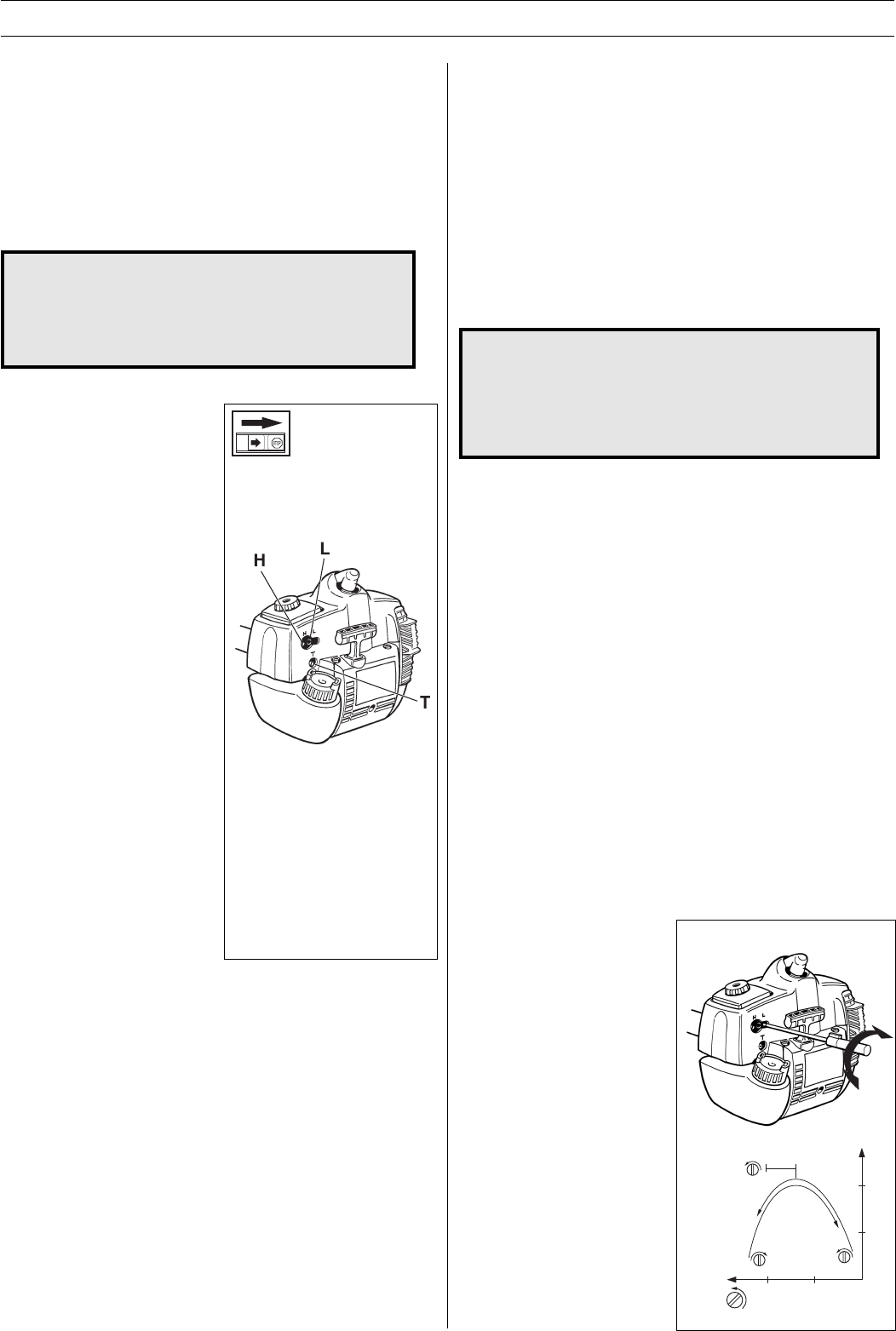

Low speed needle L

Try to fi nd the highest idling

speed, turning the low speed

needle L clockwise respective-

ly counter-clockwise. When the

highest speed has been found,

turn the low speed needle L

1/4 turn counter-clockwise.

NOTE! If the cutting attach-

ment rotates/moves in the

idling position, turn the idling

speed screw T counter-clock-

wise until the cutting attach-

ment stops.