English – 17

Maintenance

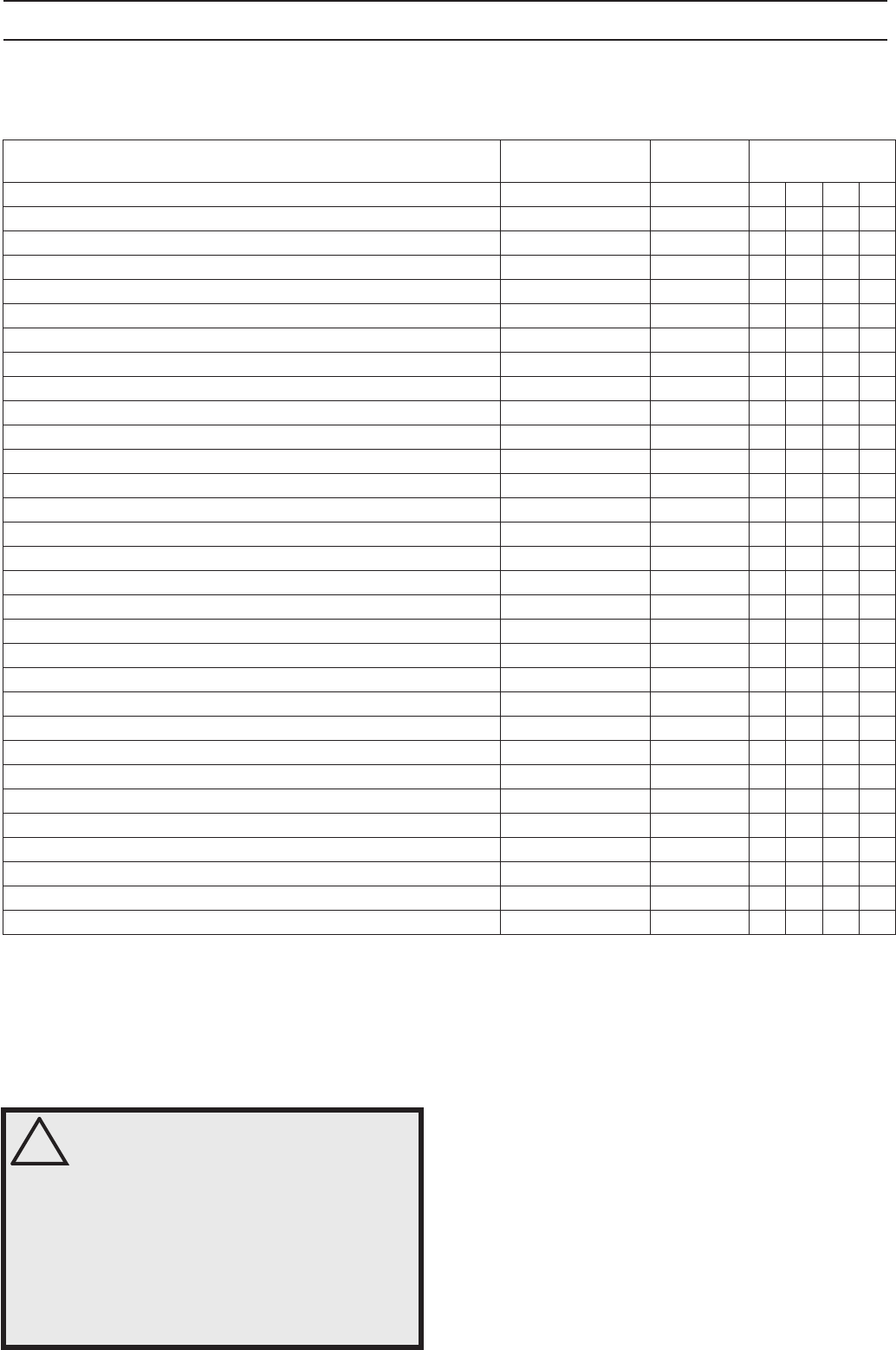

Maintenance schedule

The following is a list of the maintenance which should be conducted on the machine. For those points not described in this manual,

visit an authorised service workshop.

1)

First change after 8 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

2)

Maintenance and replacement are required more often in dusty conditions. First change after 8 hours.

3)

If the machine is used

daily it should be lubricated twice a week.

4)

Replace the oil filter every 200 hours.

5)

Replace the paper filter annually or every 200

hours.

6)

Conducted by authorised service workshop.

7)

Only 320 AWD first change after 8 hours

X = Described in this operator's manual

O = Not described in this operator's manual

Maintenance

Daily maintenance

before starting

At least

once a year

Maintenance

interval in hours

25 50 100 200

Cleaning X

Check the engine’s oil level X

Check the engine’s cooling air intake X

Check the fuel pump air filter X

Check the steering wires X

Check the battery X

Check the safety system X

Check nuts and screws O

Check for fuel and oil leakage. O

Clean around the silencer O

Clean the prefilter in the air filter

2)

X

Change engine oil

1)

X

3

X

3

Check the cutting deck X

Check the air pressure in the tyres, 60 kPa/8.5 PSI. X

Lubricate the belt adjuster

3)

X

Lubricate joints and shafts

3)

X

Adjust the brake X

Check the V-belts O

Check the cooling fins on the hydrostatic transmission O

Checking the transmission oil level X

Checking and adjusting the choke wire X

Tighten the nuts and screws O

Checking and adjusting of throttle wire X

Replace the air filter’s prefilter and paper filter

2, 5)

X X

Replace the fuel filter X

Replace the spark plug. X

Check the need to change the oil

6,7)

in the gearbox/hydraulic system O O

Change the oil filter X

Check the synchronisation between the front and rear wheels. O

Check the fuel hose. Replace if necessary .

6)

O

!

WARNING! No service procedures must be

conducted on the engine or cutting unit

unless:

The engine is switched off.

The parking brake is applied.

The ignition key is removed.

The cutting unit is disengaged.

The ignition cables are removed from the

plugs.