15

ENGLISH

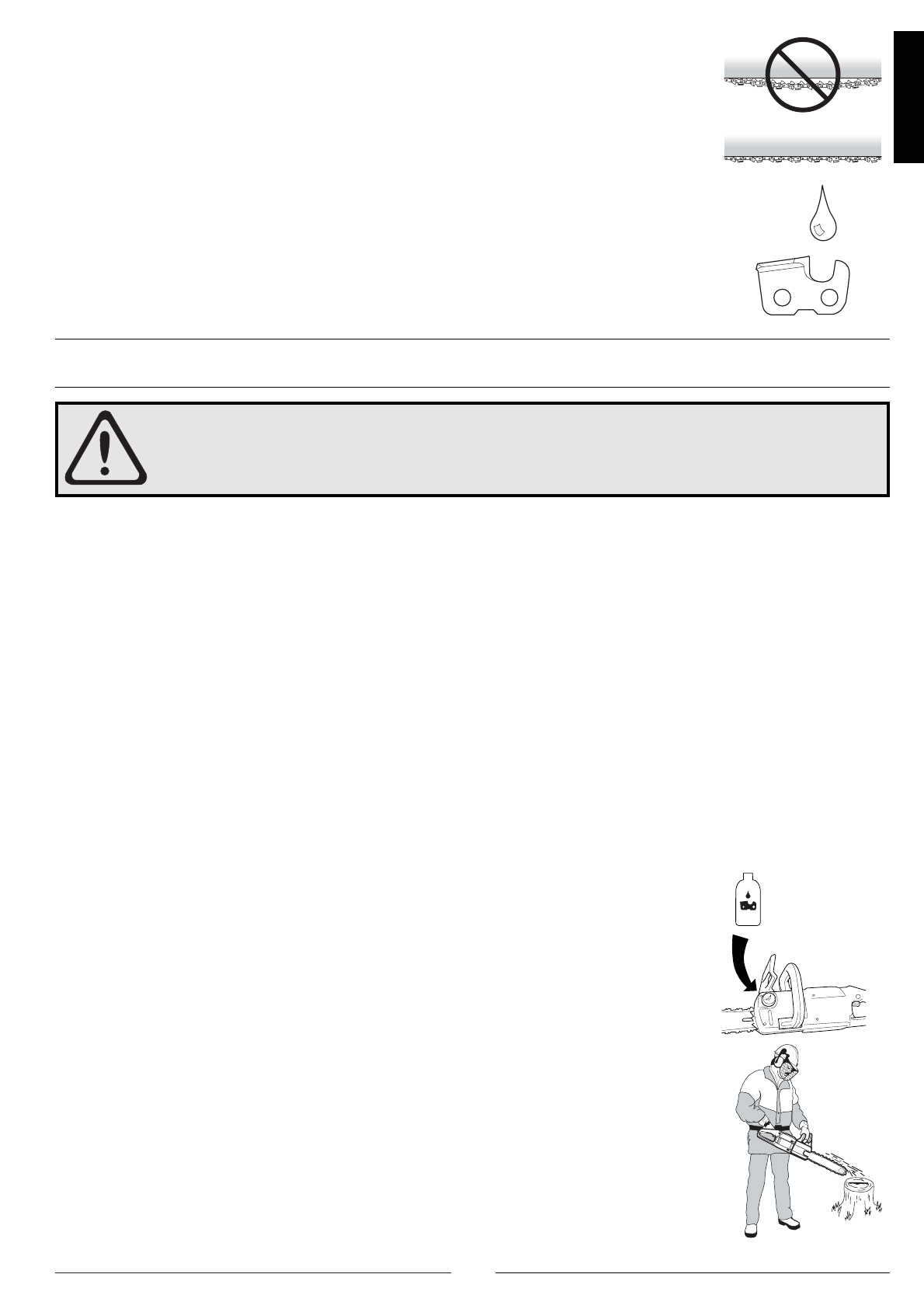

• Keep chain properly tensioned!

A loose chain derails more easily and accelerates wear on guide bar,

chain and drive socket.

• Ensure that the automatic oiling system works and that the cutting

equipment is properly maintained.

CHAIN AND GUIDE BAR LUBRICATION

CAUTION!

Inadequate lubrication can lead to cutting equipment failure and serious or fatal

personal injury.

Chain oil

• The chain and bar are lubricated by an automatic oiling system. We recommend using only chain saw oil,

which is formulated for good adhesion and flow characteristics in hot or cold weather. Nonetheless,

it is important to use the viscosity appropriate to the season. Oil thickens in subfreezing temperatures and

can overload the oil pump and cause parts to fail.

• As a manufacturer of chain saws, we have developed an ideal chain oil which, being based on vegetable

oils, is completely biodegradable. We recommend our oil for the sake of your chain and guidebar and for

the sake of the environment.

•Where chain oil is not available, EP 90 gear oil may be used.

• If you need help choosing chain oil, contact your service dealer.

• Never use old motor oil!

Used motor oil contains impurities which may be harmful to oil pump, guide bar

and chain.

Filling chain oil

• All our chain saw models feature automatic chain lubrication.

Checking automatic chain lubrication system

•Start the chain saw and point the guide bar towards a fixed, light-coloured object

at a distance of approximately 20 cm. After running the saw for a minute, a streak

of oil spatter should be clearly visible on the light surface.

•A full reservoir is sufficient for 20 minutes of steady use.