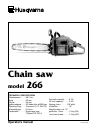

Starting the chain saw

A. Cold engine

.

1. Switch on the ignition (push the switch

is visible).

2. Pull out the choke control.

to the left so that the 1

3. Push down the throttle trigger lockout (A).

4. Open the throttle fully (B).

5. Push the throttle latch backwards (C).

Now all the controls are in starting position and the chain saw is

ready to be started.

6 Put your right foot on the plate beneath the rear handle

7. Grasp the front handle with your left hand and press the saw

against the ground.

8. Grasp the starter handle with your right hand and pull out the

starting cord slowly until the starter pawl engage.

9. Give the starting cord a short sharp tug.

NOTE!

Do not pu// the starting cord entire/y out or release the starter

hand/e in pulled out position, as this can cause damages on the

chain saw.

10. Normally the engine will start after 2-3 starting attempts Push

the choke control as soon the engine starts. Open rapidly the

throttle wide and the latch will disengage

To stop the engine push the ignition switch to the right so that the

O is visible,

B. Warm engine

Use the same starting procedure as for cold engine but without

pulling out the choke control

NOTE!

One of the most common causes of starting difficulties is that too

many starting attempts have been made with a closed choke flap,

If this is the case, remove the spark plug and wipe it dry. Open the

choke flap fully.

Before you reassemble the spark plug, we recommend you to pull

the starter handle several times to “ventilate the cylinder”, the

ignition switch in O-position.

Assemble the spark plug and make a new starting attempt with

open choke flap and full throttle.

CAUTION!

I Guide bar, chain and clutch cover must be assembled before

T

the engine ISstarted, otherwise the clutch may come loose

and cause injuries.

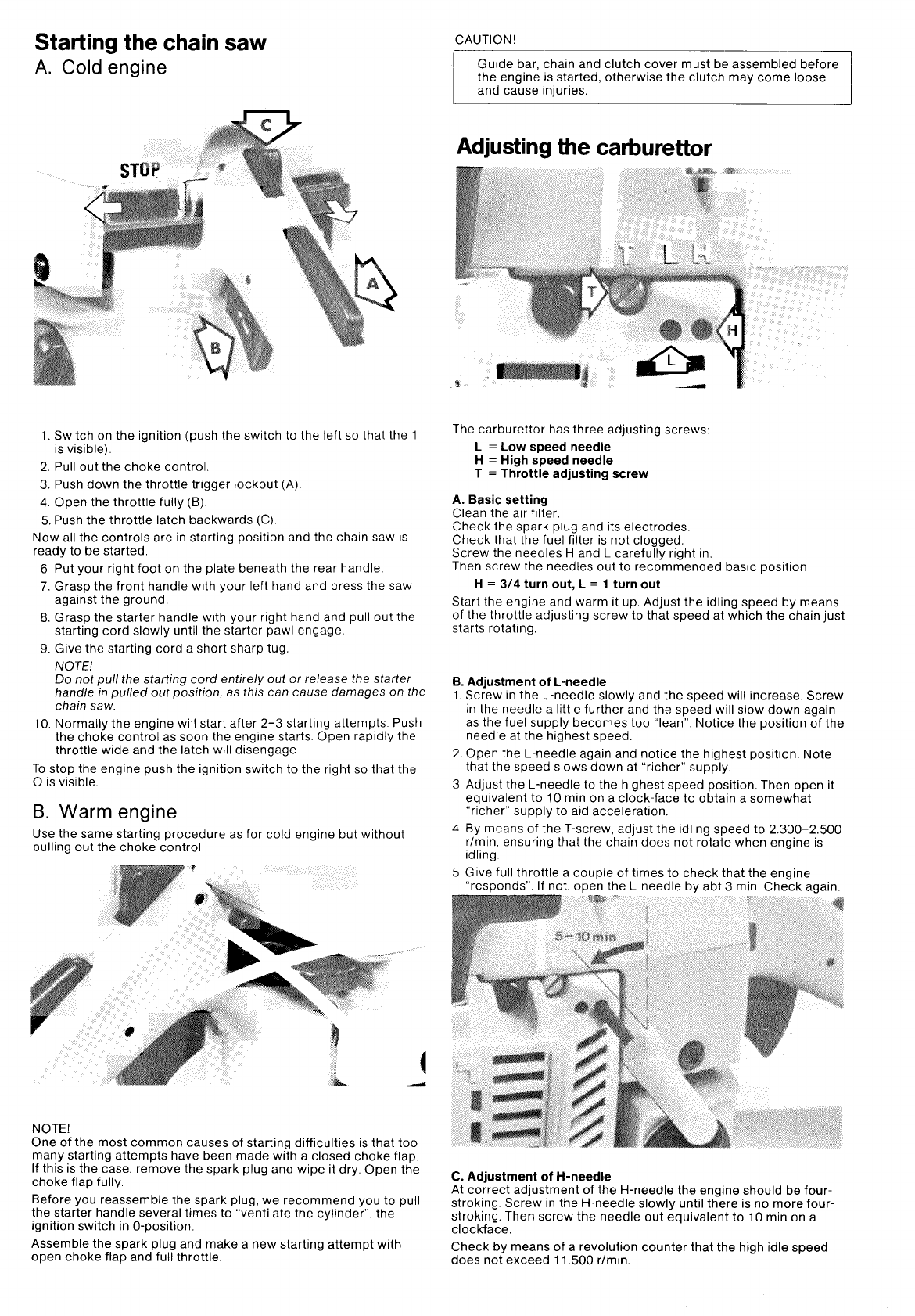

Adjusting the carburetor

The carburetor has three adjusting screws:

L = Low speed needle

H = High speed needle

T = Throttle adjusting screw

A. Basic setting

Clean the alr filter.

Check the spark plug and its electrodes.

Check that the fuel filter is not clogged.

Screw the needles H and L carefully right in.

Then screw the needles out to recommended basic position:

H = 3/4 turn out, L = 1 turn out

Start the engine and warm It up. Adjust the idling speed by means

of the throttle adjusting screw to that speed at which the chain just

starts rotating.

B. Adjustment of L-needle

1.Screw In the L-needle slowly and the speed will increase. Screw

in the needle a little further and the speed will slow down again

as the fuel supply becomes too “lean”. Notice the position of the

needle at the highest speed.

2. Open the L-needle again and notice the highest position. Note

that the speed slows down at “richer” supply.

3. Adjust the L-needle to the highest speed position. Then open it

equwalent to 10 min on a clock-face to obtain a somewhat

“richer” supply to aid acceleration.

4. By means of the T-screw, adjust the idling speed to 2.300-2.500

r/mln, ensuring that the chain does not rotate when engine is

Idling

5. Give full throttle a couple of times to check that the engine

“responds”. If not, open the L-needle by abt 3 min. Check again.

4

!

,

#

I%*LZ(~,

I‘w,,;

C. Adjustment of H-needle

At correct adjustment of the H-needle the engine should be four-

stroking. Screw in the H-needle slowly until there is no more four-

stroking. Then screw the needle out equivalent to 10 min on a

clockface.

Check by means of a revolution counter that the high idle speed

does not exceed 11.500 r/rein.