English – 29

MAINTENANCE

Carburettor

Your Husqvarna product has been designed and

manufactured to specifications that reduce harmful

emissions. After the engine has used 8-10 tanks of fuel the

engine will be run-in. To ensure that it continues to run at peak

performance and to minimise harmful exhaust emissions

after the running-in period, ask your dealer/service workshop

(who will have a rev counter at their disposal) to adjust your

carburettor.

Function

• The carburettor governs the engine’s speed via the

throttle control. Air and fuel are mixed in the carburettor.

The air/fuel mixture is adjustable. Correct adjustment is

essential to get the best performance from the machine.

• Adjusting the carburettor means that the engine is

adapted to local operating conditions, e.g. climate,

altitude, petrol and the type of 2-stroke oil.

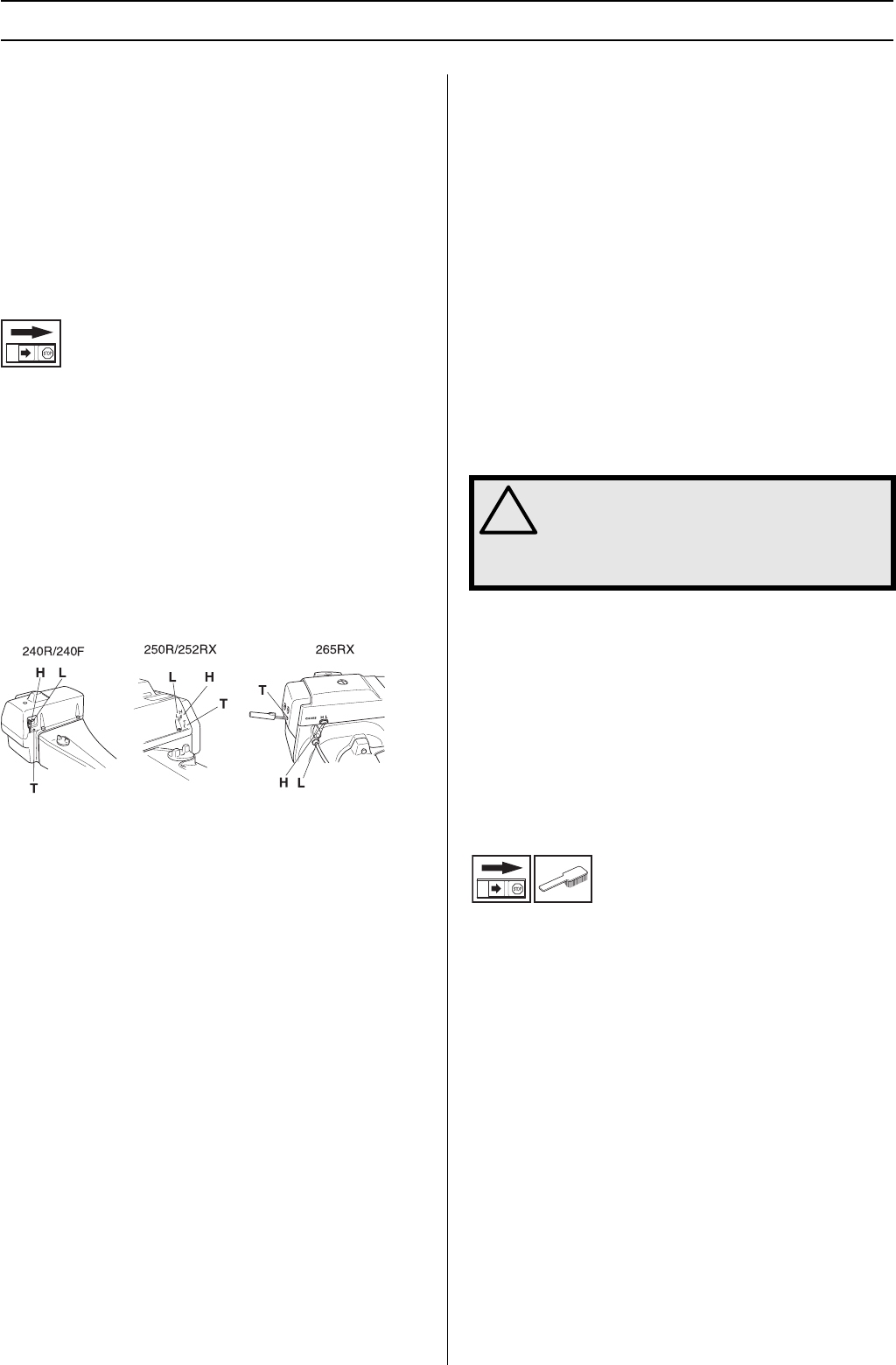

• The carburettor has three adjustment controls:

L = Low speed jet

H = High speed jet

T = Idle adjustment screw

• The L and H-jets are used to adjust the supply of fuel to

match the rate that air is admitted, which is controlled with

the throttle. If they are screwed clockwise the air/fuel ratio

becomes leaner (less fuel) and if they are turned anti-

clockwise the ratio becomes richer (more fuel). A lean

mixture gives a higher engine speed and a rich mixture

gives a lower engine speed.

• The T-screw regulates the throttle setting at idle speed. If

the T-screw is turned clockwise this gives a higher idle

speed; turning it anti-clockwise gives a lower idle speed.

Basic setting

• The basic carburettor settings are adjusted during testing

at the factory. The basic setting is richer than the optimal

setting and should be maintained for the first few hours the

machine is in use. The carburettor should then be finely

adjusted. Fine adjustment should be carried out by a

skilled technician.

The basic setting can vary between: H = 1 - 1 1/4 turns

and L = 1 - 1 1/4 turns.

CAUTION! If the cutting attachment rotates when the engine

is idling the idle adjustment screw T should be turned anti-

clockwise until the cutting attachment stops.

240R, 240F, 250R, 252RX:

Rec. idle speed 2700 rpm

265RX:

Rec. idle speed 2250 rpm

CAUTION! The machine should only be run for short periods

at its highest speed. For optimum adjustment of the

carburettor, contact a qualified dealer/service workshop that

has a revolution counter at their disposal.

Recommended max. speed: See the Technical data section.

During the running-in period (8-10 tanks of fuel) the maximum

speed should be set 600-700 rpm below the recommended

maximum speed (= open the high speed jet H a further 1/8

turn).

Muffler

CAUTION! Some mufflers are fitted with a catalytic converter.

See chapter on Technical data to see whether your machine

is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to direct

the exhaust gases away from the operator. The exhaust

gases are hot and can contain sparks, which may cause fire

if directed against dry and combustible material. Some

mufflers are equipped with a special spark arrestor mesh. If

your machine has this type of muffler, you should clean the

mesh at least once a week. This is best done with a wire

brush. On mufflers without a catalytic converter the mesh

should be cleaned weekly, or replaced if necessary. On

mufflers fitted with a catalytic converter the mesh should be

checked, and if necessary cleaned, monthly. If the mesh is

damaged it should be replaced.

!

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

stops, contact your dealer/service

workshop. Do not use the machine until it

has been correctly adjusted or repaired.