18 – English

ASSEMBLY

IMPORTANT INFORMATION

The machine must be equipped with the correct

handlebars, blade guard and harness if either a

clearing blade or grass blade are to be used.

!

WARNING!

Under no circumstances may the cutting

equipment be used without an approved

guard fitted. See the chapter

“Technical

data”

. If the wrong guard or a defective

guard is fitted this can cause serious

personal injury.

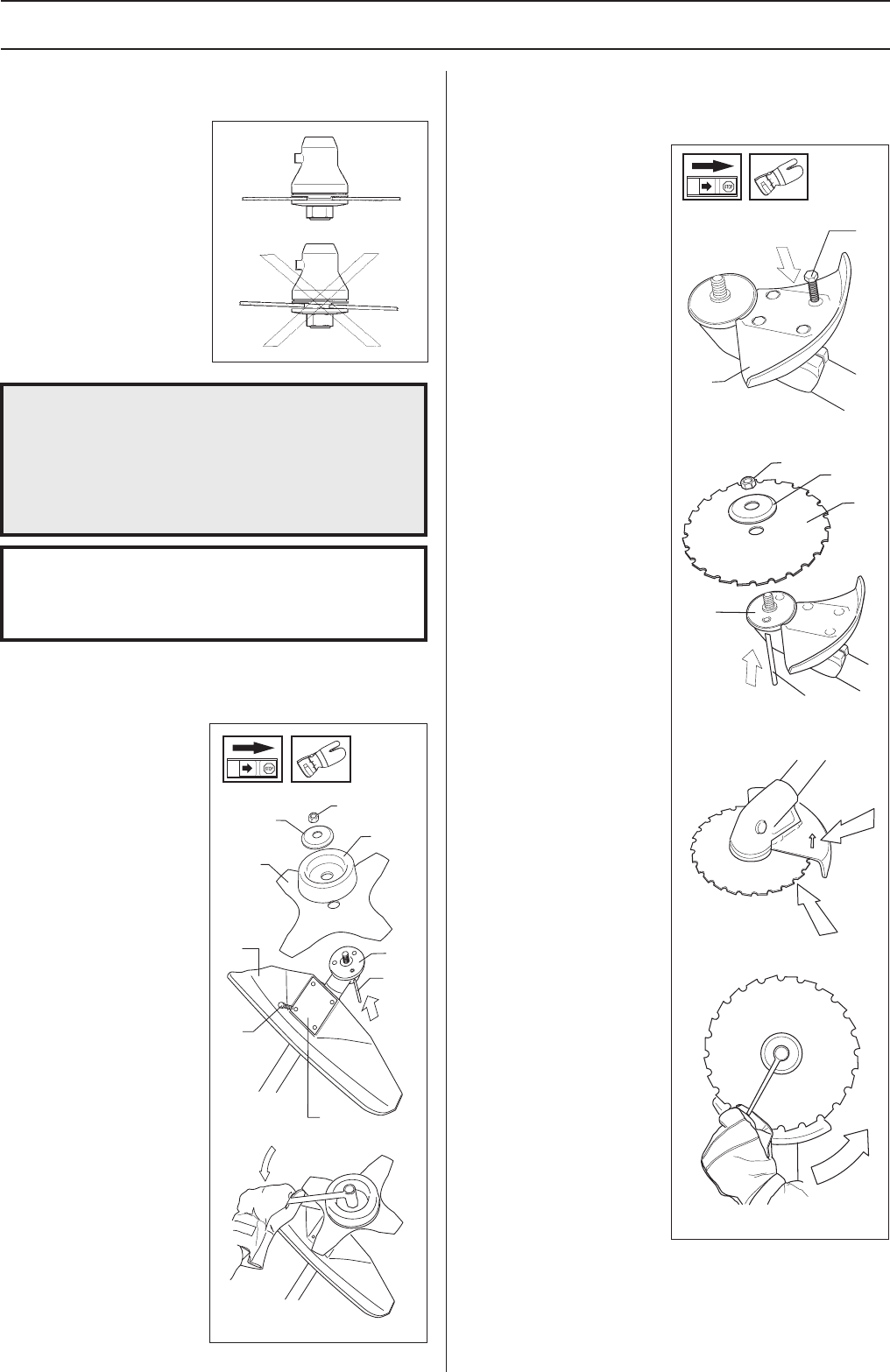

• The guard (A) is fitted

using 4 screws (L) and

the support plate (M) as

set out in the diagram.

NOTE! Use the

recommended blade

guard.

• Fit the drive disc (B) on

the output axle.

• Turn the blade axle until

one of the holes in the

drive disc aligns with the

hole in the gear housing.

• Insert the locking pin (C)

in the hole so that the

axle is locked.

• Place the blade (D),

support cup (E) and

support flange (F) on the

output axle.

• Fit the nut (G). The

tightening torque of the

nut is 35-50 Nm (3,5 - 5

kpm). Use the socket

spanner in the tool kit.

Hold the handle of the

spanner as close to the

blade guard as possible.

The nut is tightened

when the spanner is

G

F

E

D

B

C

A

L

M

turned against the direction of rotation (left-hand thread).

Assembly of the blade and trimmer

head

It is extremely important

that the disc drive’s/support

flange’s guide engages

correctly in the cutting

equipment’s centre hole

when assembling the cutting

equipment. Cutting

equipment assembled

incorrectly can result in

serious and/or fatal personal

injury.

Assembling the blade guard and

grass blade

Assembling the blade guard and

clearing blade

• The guard (A) is fitted

using 4 screws (L) as set

out in the diagram.

NOTE! Use the

recommended blade

guard.

• Fit the drive disc (B) on

the output axle.

• Turn the blade axle until

one of the holes in the

drive disc aligns with the

hole in the gear housing.

• Insert the locking pin (C)

in the hole so that the

axle is locked.

• Place the blade (D) and

support flange (F) on the

output axle.

• Fit the nut (G). The

tightening torque of the

nut is 35-50 Nm (3.5 - 5

kpm). Use the socket

spanner in the tool kit.

Hold the handle of the

spanner as close to the

blade guard as possible.

The nut is tightened

when the spanner is

turned against the

direction of rotation (left-

hand thread).

• When slacking off and

tightening the saw blade

nut, the hands may be

injured by the blade

teeth. Always hold your

hand protected by the

blade guard. This is

facilitated by the use of a

long box spanner. The

illustration shows the area

in which you should keep

the box spanner.

L

A

G

F

D

B

C