26 – English

Lubrication

Checking the transmission oil level

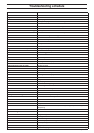

1 Remove the transmission cover. Undo the two screws

(one on each side) and lift off the transmission cover.

2 Rider 213 C, Rider 216 Check that there is oil in the

transmission’s oil tank. Fill if necessary with engine oil

SAE 10W/40 (class SF–CC).

Rider 216 AWD

Check that there is oil in the transmission’s oil tank. Fill if

necessary with oil Synthetic 10W/50

The oil and filter should be changed by an authorised service

representative, as described in the Workshop Manual.

Work on the system entails particular demands on

cleanliness and the system must be vented before the

machine is used.

Lubricating the belt adjuster

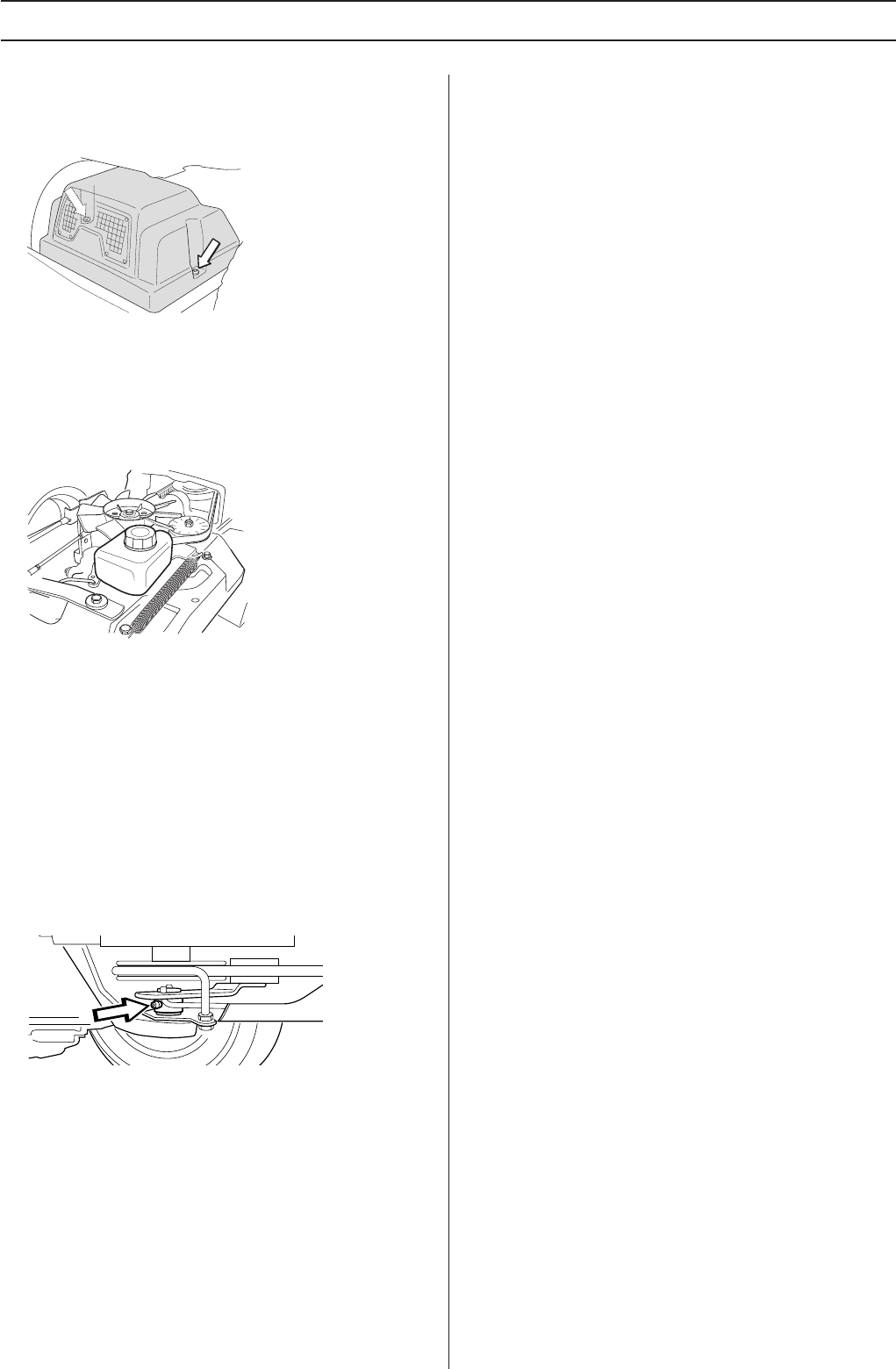

The belt adjuster should be lubricated regularly using good

quality molybdenum disulphide grease*.

Lubricate using a grease gun, 1 nipple from the right-hand

side under the engine’s lower belt pulley, until grease is forced

out.

With daily use, lubrication should be carried out twice weekly.

General lubrication

All joints and bearings are lubricated using molybdenum

disulphide grease during manufacture. Continue to lubricate

using the same type of grease *. Lubricate the steering and

control wires using engine oil.

Carry out this lubrication regularly; with daily use, the

machine should be lubricated twice weekly.

*Grease from well-known brand names (petrochemical

companies, etc.) usually maintains a good quality. The most

important property is that the grease provides good

protection against corrosion.