20 – English

MAINTENANCE

Cooling system

To maintain as low an

operating temperature as

possible the engine is

equipped with a cooling

system.

The cooling system consists

of:

1.An air intake on the

starter unit.

2.Cooling fins on the

flywheel.

3.Cooling fins on the

cylinder

4.Cylinder cover (leads cold

air onto the cylinder).

Clean the cooling system

using a brush at least once a

week, in difficult conditions

more often.

A dirty or blocked cooling

system leads to the engine

overheating resulting in

damage to the cylinder and

piston.

Air filter

The air filter should be

cleaned regularly removing

dust and dirt to avoid:

• carburettor malfunction

• starting problems

• reduced engine power

• unnecessary wear to

engine parts

• abnormal fuel

consumption

Clean the filter after every

25 hours or more regularly

if operating conditions are

exceptionally dusty.

Cleaning the air filter

Dismantle the air filter

cover and remove the air

filter. Wash in clean, warm

soapy water. Ensure that the

filter is dry before refitting.

An air filter used for a long

period of time can never be

cleaned completely. There-

fore it is necessary to replace

the filter from time to time

with a new filter. A dam-

aged air filter must always

be replaced.

1

2

4

3

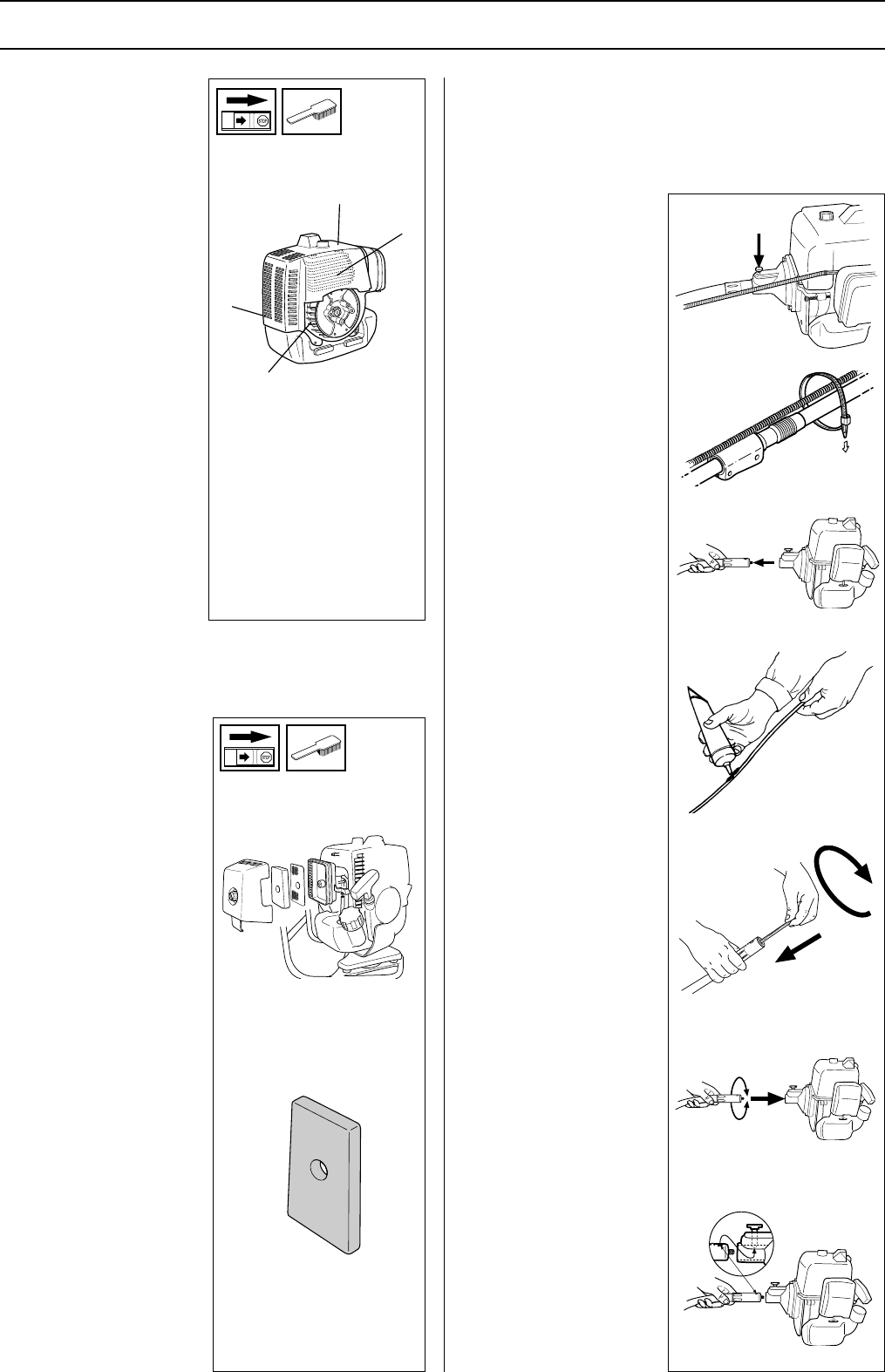

Drive shaft

The flexible drive shaft is lubricated with special grease. The

shaft must be lubricated at least every 25 working hours. A

tube of drive shaft grease is supplied with every machine.

NOTE! Do not use gearbox grease on the drive shaft.

• Lift up the locking button

that holds the drive shaft

sleeve in the clutch cover.

• Remove the clip that

holds the throttle cable on

the drive shaft.

• Pull the drive shaft sleeve

out of the clutch cover.

• Remove the drive shaft

from the sleeve either by

shaking it out or pulling it

out using pliers.

• Coat the surface of the

shaft with grease from the

tube. Spread it out using a

brush or rag.

• Slide the drive shaft back

into the sleeve. Make sure

the shaft engages correctly

by turning it and pushing

at the same time.

• When the shaft is

correctly installed in the

sleeve the end of the shaft

should project about 10

mm beyond the edge of

the sleeve.

• Rotate the shaft and push

it in at the same time.

• Install the drive shaft

sleeve in the clutch cover

so that the hole is

positioned directly

underneath the locking

button on the clutch

cover.