English – 19

WARNING!

No service procedures must be conducted on the engine or cutting unit unless:

• The engine is switched off.

• The ignition key is removed.

• The ignition cable is removed from the plug.

• The parking brake is applied.

• The cutting unit is disengaged.

Maintenance

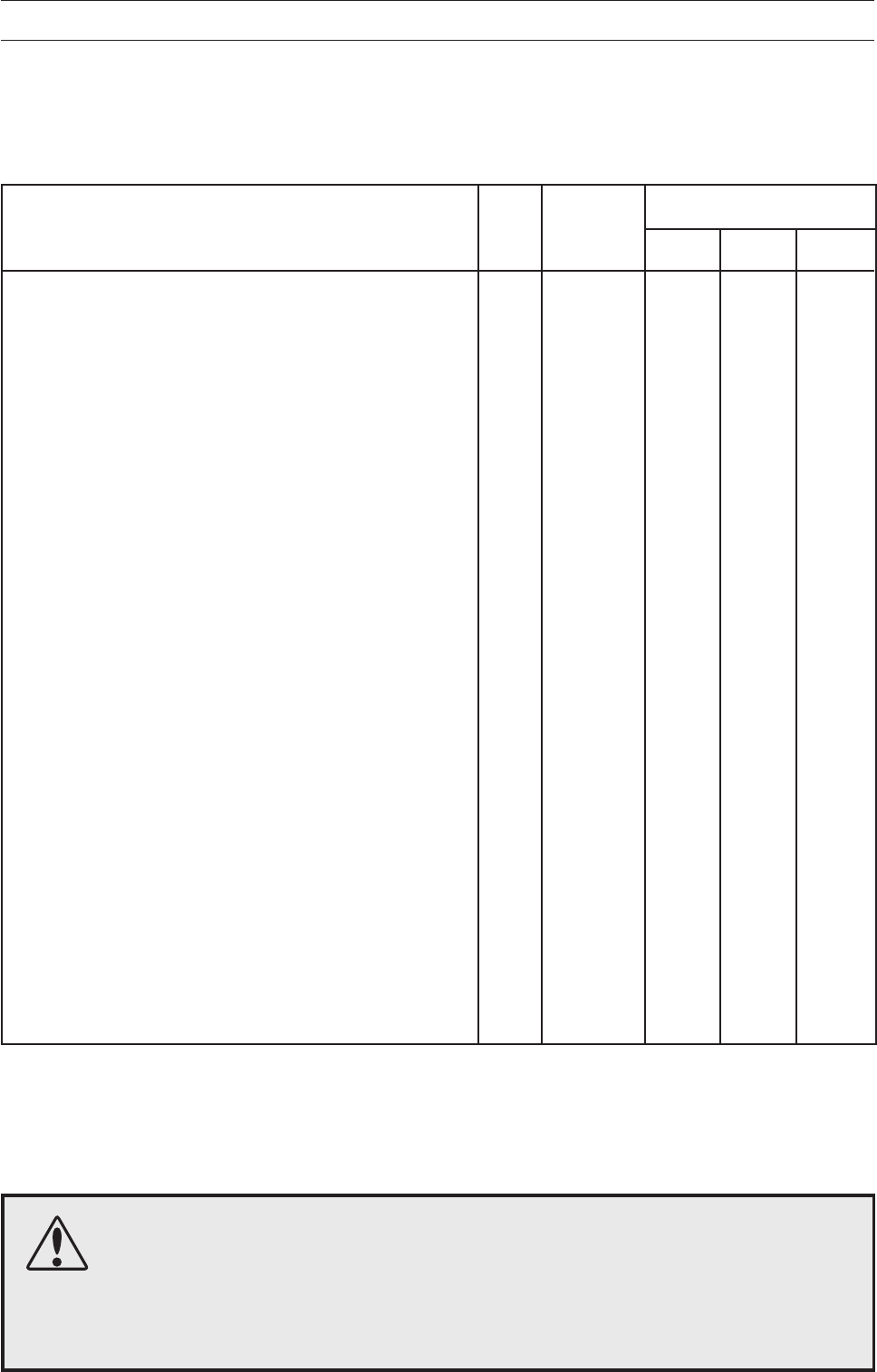

5025

100

MAINTENANCE

Page

Maintenance interval

in hours

Daily

mainte-

nance

before start

Maintenance schedule

The following is a list of the maintenance which should be conducted on the machine. For the items which

are not described in these instructions go to an authorised service workshop.

Check the engine’s oil level 35 ●

Check the engine’s cooling air inlet 28 ●

Check the fuel pump’s air filter 26 ●

Check the steering wires 22 ●

Check the brakes 23 ●

Check the battery 26 ●

Check the safety system 27 ●

Check screws and nuts – ❍

Check for fuel and oil leakage – ❍

Change the engine oil

1)

35 ●

Clean the air filter’s pre-filter (foam plastic)

2)

25 ●

Check the cutting unit 29 ●

Check the tyre pressures (60 kPa) 28 ●

Lubricating the belt adjuster

3)

36 ●

Lubricate joints and shafts

3)

37 ●

Adjust the brakes – Rider 11 and Rider 11 Bio 23 ●

Check the V-belts – ❍

Check the transmission’s cooling flanges –– ❍

Rider 13 and Rider 13 Bio

Check the transmission’s oil level – Rider 13 and 36 ●

Rider 13 Bio

Adjust the brakes – Rider 13 and Rider 13 Bio 23 ●

Check and adjust the throttle wire 24 ●

Clean the cooling flanges on the engine and – ❍

transmission

2,4)

Replace the air filter’s pre-filter and paper filter

2)

25 ●

Replace the fuel filter 24 ●

Replace the plug – ❍

● = Described in these instructions.

❍ = Not described in these instructions.

1)

First change after 5 hours.

2)

During dusty conditions cleaning and replacement should be more frequent.

3)

For daily use of the

machine lubrication should be conducted twice a week.

4)

Conducted by authorised service workshop.