MAINTENANCE

English – 37

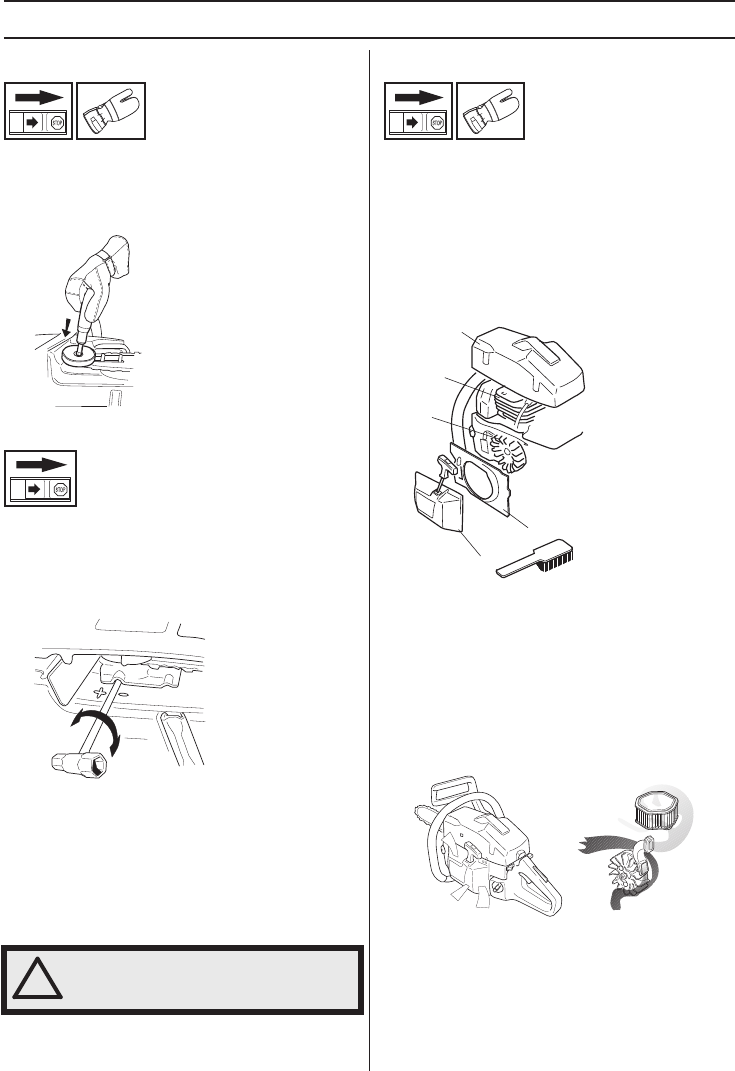

Needle bearing lubrication

The clutch drum has a needle bearing on the output shaft.

This needle bearing must be lubricated regularly (once a

week). NB! Use a high-quality bearing grease or engine

oil. See instructions under the heading Cutting

equipment.

Adjustment of the oil pump

The oil pump is adjustable. Adjustments are made by

turning the screw using a screwdriver or combination

spanner. The machine is supplied from the factory set to

1 turn open. Turning the screw clockwise will reduce the

oil flow and turning the screw anti-clockwise will increase

the oil flow.

Recommended settings:

These recommendations apply to Husqvarna’s chain oil,

for other chain oils increase the oil flow by one step.

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Air intake on the starter.

2 Air guide plate.

3 Fins on the flywheel.

4 Cooling fins on the cylinder.

5 Cylinder cover (directs cold air over the cylinder).

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

”Air Injection” centrifugal

cleaning

Centrifugal cleaning means the following: All air to the

carburettor passes through the starter. Dirt and dust is

centrifuged out by the cooling fan.

IMPORTANT! In order to maintain operation of the

centrifugal cleaning system it must be regularly

maintained. Clean the air intake to the starter, the fins on

the flywheel, the space around the flywheel, inlet pipe and

carburettor compartment.

Bar 18"-20": 0 turns from the closed position.

Bar 20"-24": 3/4 turns from the closed position.

Bar 24"-28": 1 1/2 turns from the closed position.

Bar 28" and longer: 1 3/4 turns from the closed position.

!

WARNING! The engine must not be

running when making adjustments.

1

2

5

4

3