Cleaning Spark Arrestor Screen

24 www.honeywellgenerators.com HW6200/HW6200L Portable Electrical Generator Owner’s Manual

6. Inspect spark plug.

If spark plug is damaged or excessively worn, or if

insulator is cracked or chipped, use a new spark

plug.

If spark plug is in good condition, reuse existing

spark plug.

7. If reusing spark plug, clean spark plug with wire

brush.

8. Measure spark plug gap with spark plug gauge.

Gap should be: (0.028-0.031 in) (0.70-0.80 mm).

9. If necessary, adjust gap by carefully bending side

electrode.

10. Inspect spark plug washer and verify it is in good con-

dition.

11. Reinstall spark plug by hand to prevent cross-thread-

ing.

12. After spark plug is seated, tighten with spark plug

wrench to compress washer.

If installing a new spark plug, tighten l/2 turn after

the spark plug seats to compress the washer.

If reinstalling a used spark plug, tighten l/8 - l/4 turn

after the spark plug seats to compress the washer.

Cleaning Spark Arrestor Screen

Generator muffler is equipped with spark arrestor screen,

which must be cleaned according to maintenance sched-

ule (Table 2).

1. Stop generator if engine is running. Allow to com-

pletely cool.

2. Place the generator on a flat, level surface.

3. Using a socket wrench with 8 mm socket, remove

spark arrestor enclosure panel bolts.

4. Pull off enclosure panel.

5. Using a screwdriver, loosen and remove screw hold-

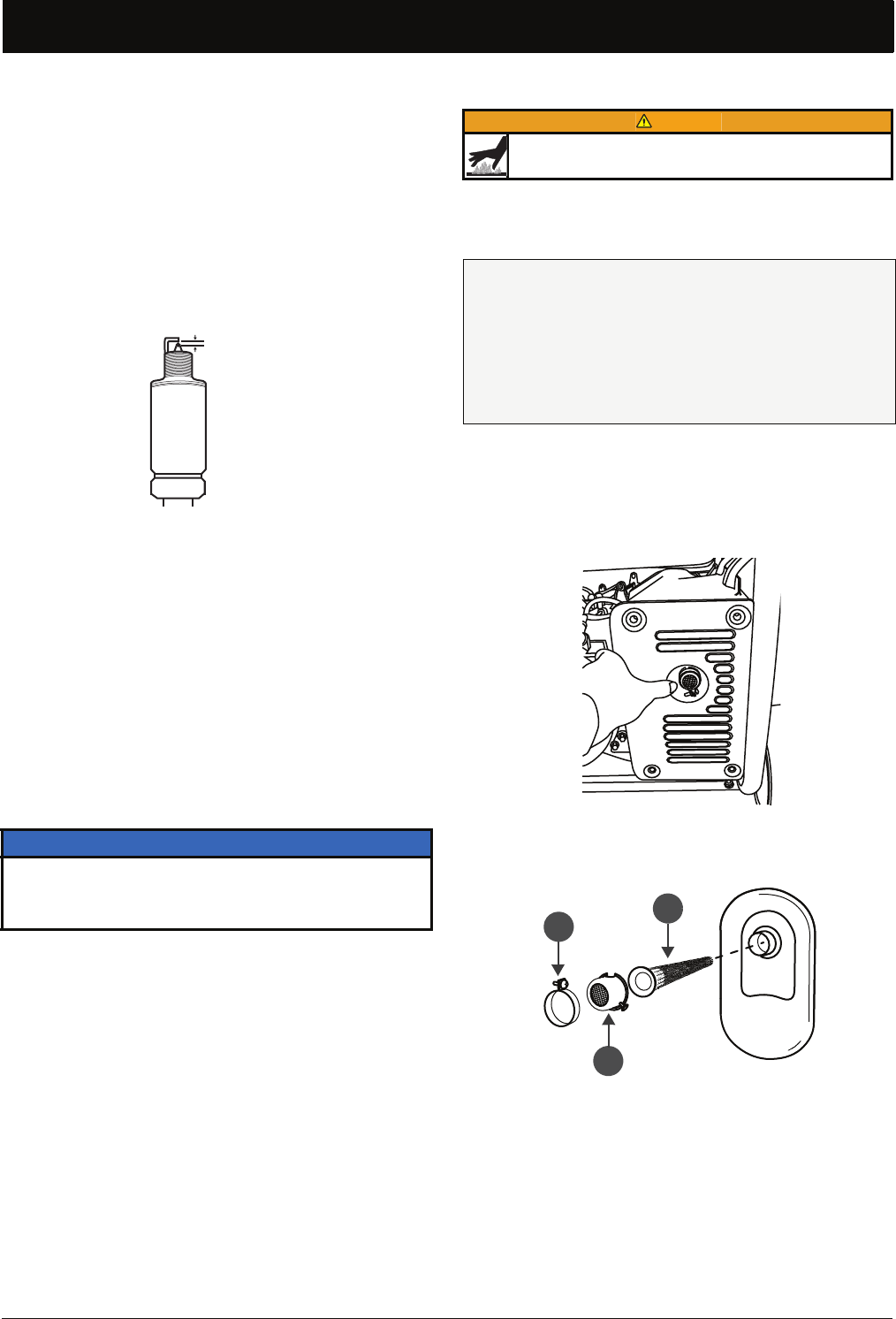

ing spark arrestor clamp (A).

6. Slide off spark arrestor clamp.

7. Using a socket wrench with a 7/32” socket, remove

the retaining screw on spark arrestor screen cap (B);

pull off cap.

8. Pull out spark arrestor screen (C).

FIGURE 48: Correct Spark Plug Gap

NOTICE

Spark plug must be securely tightened. An improperly tight-

ened spark plug can become very hot and could damage

engine. Never use spark plugs that have an improper heat

range. Use only recommended spark plugs or equivalent.

0.028-0.031 in

(0.70-0.80 mm)

Muffler reaches temperatures that can cause serious

burns if touched. NEVER touch hot surfaces.

To clean spark arrestor screen, you will need:

1/4” socket wrench

8 mm socket

7/32” socket

#2 Phillips screwdriver

Wire brush

FIGURE 49: Remove Spark Arrestor Enclosure Panel

FIGURE 50: Spark Arrestor Assembly

WARNING

A

B

C