Page 27

INCORRECT

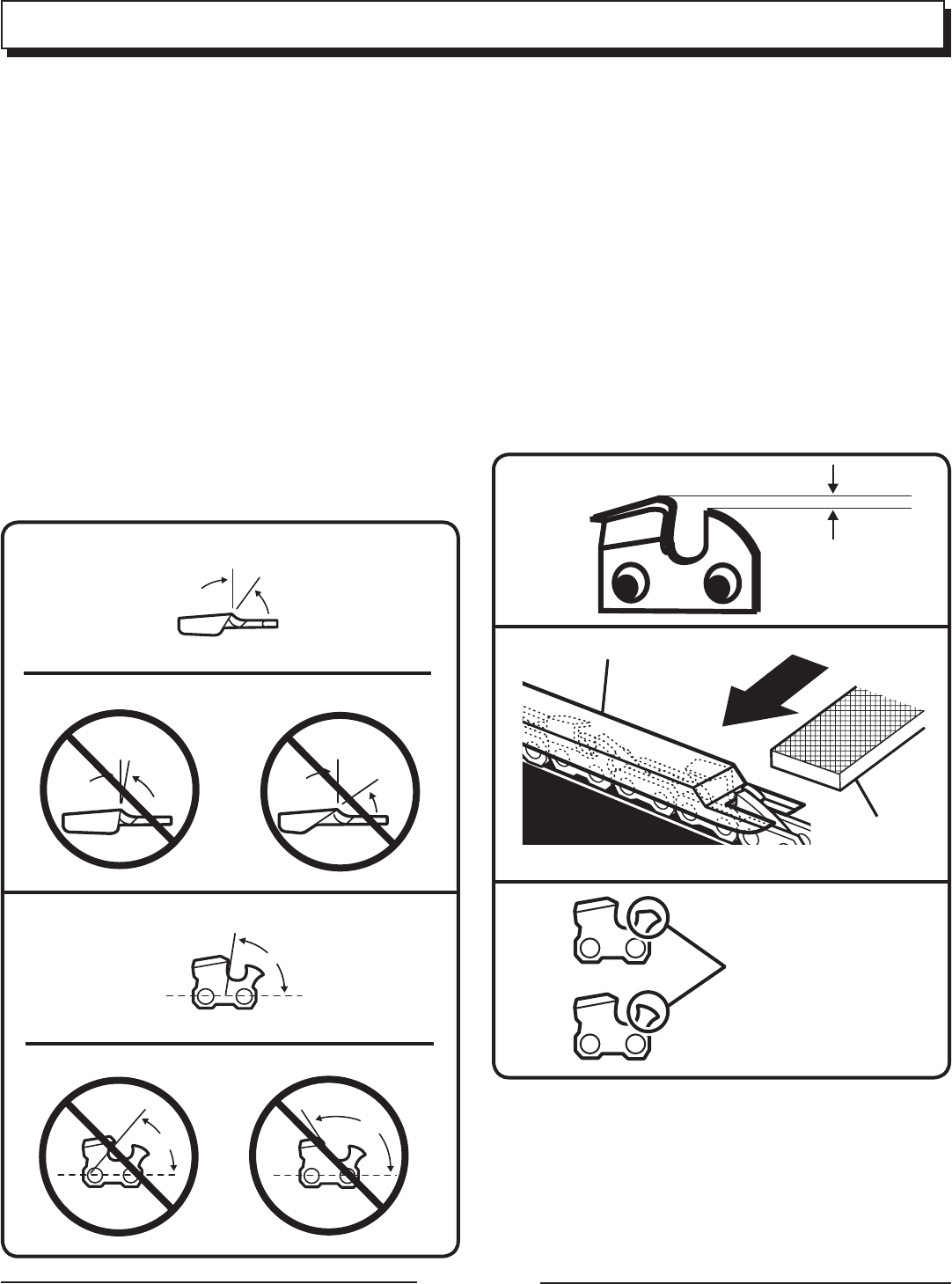

MORE THAN 30°

TOP PLATE FILING ANGLE

LESS THAN 30°

Fig. 53

30°

CORRECT

INCORRECT

BACKWARD SLOPE

SIDE PLATE FILING ANGLE

Fig. 54

80°

CORRECT

HOOK

FLAT FILE

DEPTH GAUGE JOINTER

Fig. 56

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT

Fig. 57

MAINTENANCE

TOP PLATE FILING ANGLE

See Figure 53.

CORRECT 30° – file holders are marked with guide

marks to align file properly to produce correct top plate

angle.

LESS THAN 30° – for cross cutting.

MORE THAN 30° – feathered edge dulls quickly.

SIDE PLATE ANGLE

See Figure 54.

CORRECT 80° – Produced automatically if you use the

correct diameter file in the file holder.

HOOK – “Grabs” and dulls quickly; increases the

potential of KICKBACK. Results from using a file with

a diameter too small or a file held too low.

BACKWARD SLOPE – Needs too much feed pressure;

causes excessive wear to the bar and chain. Results

from using a file with a diameter too large or file held

too high.

Fig. 55

RAKER (DEPTH GAUGE) CLEARANCE

.025 in.

MAINTAINING DEPTH GAUGE CLEARANCE

See Figure 55 - 57.

Maintain the depth gauge at a clearance of .025 in. Use

a depth gauge tool for checking the depth gauge clear-

ances.

Every time the chain is filed, check the depth gauge

clearance.

Use a flat file and a depth gauge jointer to lower all gauges

uniformly. Use a .025 in. depth gauge jointer. After lower-

ing each depth gauge, restore original shape by rounding

the front. Be careful not to damage adjoining drive links

with the edge of the file.

Depth gauges must be adjusted with the flat file in the

same direction the adjoining cutter was filed with the

round file. Use care not to contact cutter face with flat

file when adjusting depth gauges.