12

English

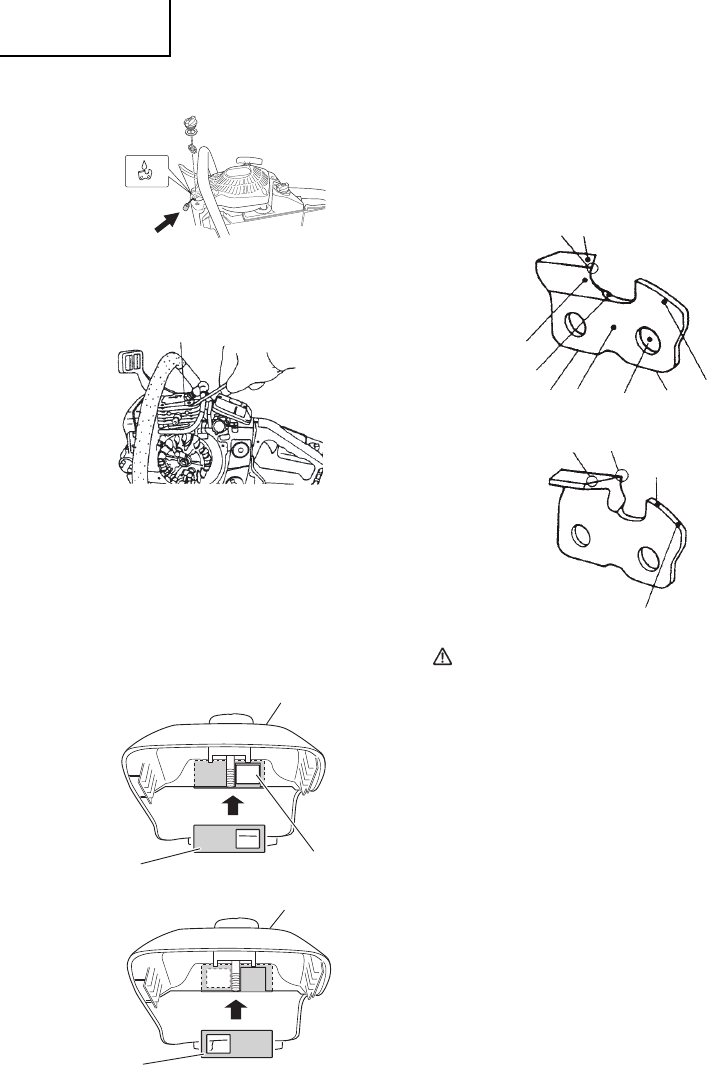

Chain oil fi lter (Fig. 37)

Remove the oil fi lter and thoroughly wash it in solvent.

Fig. 37

Cleaning the cylinder fi ns (Fig. 38)

When wood chips are caught between cylinder fi ns (44), the engine

may overheat, resulting in lower output. To avoid this, always keep

cylinder fi ns and fan case clean.

44

Fig. 38

Icing protection system (Fig. 39, 40)

This system is to protect carburetor from icing when the unit is

operated in winter time.

1. When you need icing system work, remove air fi lter cover (41).

Pull out the shutter (45) from inside the air fi lter cover and

reinstall it in winter

time position by turning half-way. (Fig. 39)

This will allow heated air to fl ow from cylinder side to carburetor

cabin through the opening (46).

NOTE

When winter time has been over and carburetor will not suff er from

icing, make sure that the shutter is reinstalled in ordinary position

(Fig.

40).

45

46

41

Fig. 39

45

41

Fig. 40

For long-term storage

Drain all fuel from the fuel tank. Start and let engine run until it stops.

Repair any damage which has resulted from use. Clean the unit with

a clean rag, or the use of high pressure air hose. Put a few drops of

two-cycle engine oil

into the cylinder through the spark plug hole,

and spin the engine over several times to distribute oil.

Cover the unit and store it in a dry area.

CHAIN SHARPENING

Parts of a cutter (Fig. 41, 42)

48

47

49

50

51

52

53

54

55

Fig. 41

56

57

58

59

Fig. 42

WARNING

○ Gloves should be used when sharpening chain.

○ Be sure to round off the front edge to reduce the chance of

kickback or tie-strap breakage.

47. To p plate

48. Working corner

49. Side plate

50. Gullet

51. Heel

52. Chassis

53 Rivet hole

54. Toe

55. Depth gauge

56. Correct angle on top plate

(degree of angle depends on chain

type)

57. Slightly protruding “hook” or point (curve on non-chisel chain)

58. Top of depth gauge at correct height below top plate

59. Front of depth gauge rounded off

LOWERING DEPTH GAUGES WITH A FILE

1) If you sharpen your cutters with a fi le holder, check

and lower the

depth.

2) Check depth gauges every third sharpening.

3) Place depth gauge tool on cutter. If depth gauge projects, fi le

it level with the top of the tool. Always fi le from the inside of the

chain toward an outside cutter. (Fig. 43)