9 -33

7. Replace the vent caps. It is not necessary to

tighten more than finger tight.

8. Wash off the battery to remove electrolyte which

may have spilled.

Battery Electrolyte First Aid

External contact:

Flush with water.

Eyes:

Flush with water for at least 15 minutes and get

medical attention immediately!

I

nternal contact:

Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or vegetable

oil. Get medical attention immediately!

IMPORTANT:

In case of internal contact, DO NOT

induce vomiting!

Inspection, Cleaning, Drying, and Maintenance

Inspect the top of battery, terminals, cables, terminal

posts, and case for any accumulation of dirt, corrosion

cracks or loose or broken parts. Keep battery and its

terminals clean. Inspect monthly to maintain best

performance. Replace battery if damaged.

Remove hold down and bolt and lift battery out. Clean

or service battery away from unit. Remove corrosion

from battery terminals and cable connections with wire

brush, then wash with a weak baking soda solution.

Scrub the exterior of the battery and cable terminals

with a nonmetallic brush which has been dipped into a

mixture of baking soda and water.

After cleaning, apply a thin coat of grease or petroleum

jelly to terminals and cable ends to retard corrosion.

Reinstall battery.

Check the alternator voltage regulator output (if used)

at every periodic maintenance inspection. Over

charging is a common cause of battery failure.

Electrolyte Level

Every 25 hours of operation, check electrolyte level of

each cell by removing caps one at a time. The

electrolyte level should be at level indicated. Use

distilled water to fill each cell if needed. Install and

tighten each cap after checking.

IMPORTANT:

When distilled water is added to battery

during freezing weather, battery must be charged to

mix water with electrolyte, or water will remain at top

and freeze.

Charging

ALWAYS follow information provided on battery by

battery manufacturer. Contact battery manufacturer for

extensive instructions to charge battery.

Place unit on a level surface, shut off engine and open

battery compartment to gain access to battery.

Disconnect negative (-) cable first, then positive (+)

cable.

To charge battery:

1. Loosen strap and remove battery from unit.

2. Place battery on bench or other well ventilated

place where electrolyte spill will not create

damage.

3. Remove caps and fill each cell to level indicated

with electrolyte at 1.265 specific gravity at 80

o

F

(27

o

C).

4. Let battery stand for one half hour.

5. Check electrolyte level and add more if necessary.

6. Connect positive (+) lead of charger to positive (+)

terminal, and negative (-) lead to negative (-)

terminal.

7. Charge the battery at two and a half amps for ten

hours or until all cells are gassing freely and the

specific gravity is constant over three 30 minute

intervals.

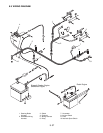

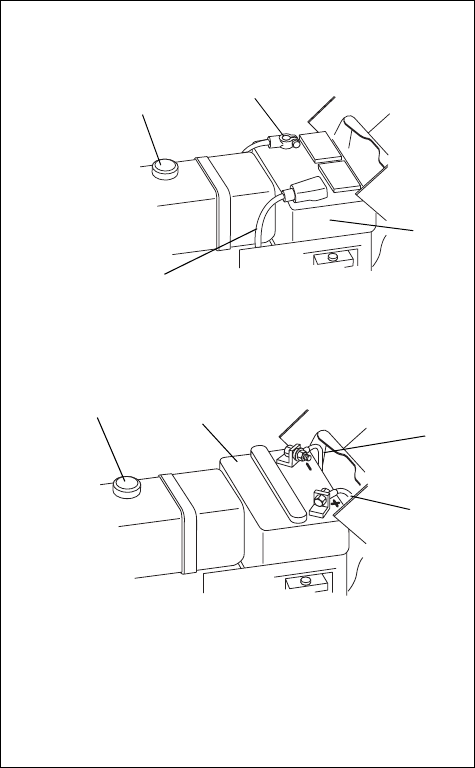

Models with Briggs & Stratton Engines

Models with Robin Engines

1

1

2

2

3

3

4

4

Figure 30

1. Fuel Cap

2. Negative Battery Cable

3. Battery

4. Positive Battery Cable

and Kohler Engines