308–507

4

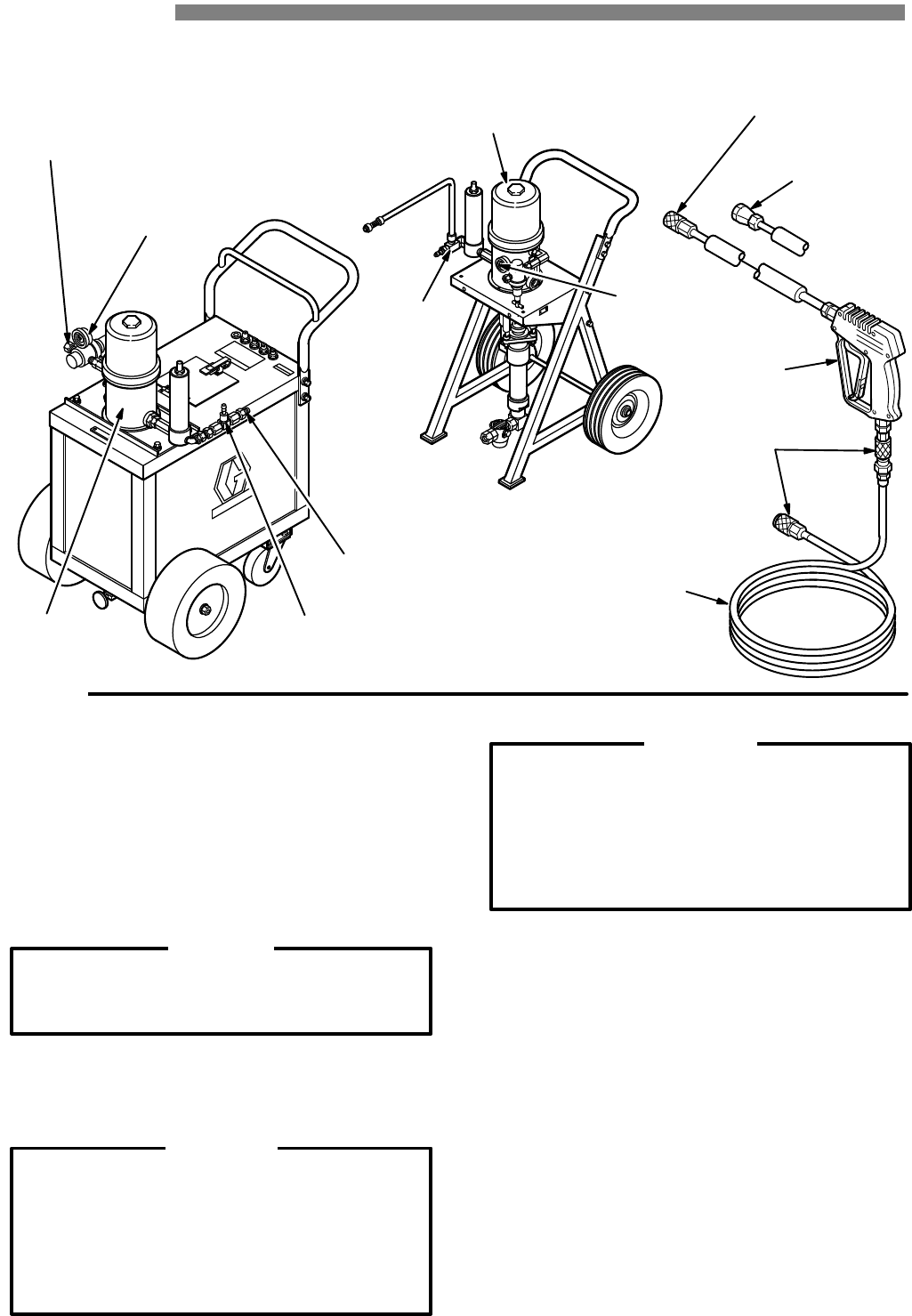

INSTALLATION

Figure

1

SPRAY

GUN

SPRAY

HOSE

QUICK

COUPLERS

QUICK COUPLER

(800–295 ONL

Y)

ADJUST-

ABLE

NOZZLE

(800–412 &

800–413)

AIR INLET

CONNECTION

AIR

MOTOR

CHEMICAL

INJECTOR

QUICK

COUPLER

AIR

MOTOR

AIR

PRESSURE

REGULATOR

CHEMICAL

INJECTOR

AIR

PRESSURE

REGULATOR

Check for Shipping Damage

The unit should be checked for any damage that may

have

occurred in shipping. Any damage should be noted

and

the

carrier notified immediately

.

Set Up

Connect

the high pressure hose between the pump outlet

and the gun inlet. Both of these connections are made

with

quick couplers.

CAUTION

Up to 100 ft (30 m) of high pressure hose may

be used.

Longer hoses may af fect sprayer

performance,

and chemical injector

performance.

Install the appropriate spray tip on the wand (800–295

only).

See Installing and Changing Spray T

ips.

Connect to Water Supply

CAUTION

Before attaching to the water supply, check your

local plumbing code regarding

cross–connection

to the water supply . A backflow preventer P/N

801–133 is available to prevent backflow of

contaminated water into the fresh water supply .

Install it upstream from the pump (800–412 &

800–413

only).

CAUTION

If inlet water pressure is over 60 psi (4.1 bar) a

regulating water valve P/N 800–258 must be

installed

at the garden

hose connection (800–412

&

800–413 only).

Do not exceed 20 0_F (93 _C) inlet water

temperature.

Connect

a hose with at least a 3/4 inch (19 mm) ID from

the water supply to the unit’

s 3/4 inch garden

hose

inlet.

The supply hose should not be more than 50 ft (15 m)

long.

NOTE: The water source at the unit

must

have a

minimum

flow rate equal to

that of the unit (see

Technical

Data, inside back cover).

Connect to Air Supply

Be

sure that

the air supply has a minimum flow rate equal

to

the air consumption of the motor and

that the pressure

is less than the maximum allowed (see Technical Data,

inside

back cover).