Repair

3A0540L 13

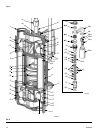

Lower Reassembly

1. Lubricate the new piston seal (25*) and install it on

the piston.

2. Install the piston plate (24) with the beveled edge

facing away from the piston seal. See F

IG

. 7.

3. Install o-ring retainer (20). Lubricate o-ring (22*) and

slide it on over the threads of piston shaft. Apply

high strength (red) Loctite

®

263 or 2760 to entire

length of the piston rod (19) threads. Sealant must

be allowed to cure for a minimum of 12 hours before

use. Screw the piston nut (21) snugly against the

o-ring retainer (20). Apply lubricant to the bottom

face of the piston nut (21). Assemble o-ring (23*)

and install in the groove on the piston nut. Screw

rod (19) into piston (26) until snug. Tighten piston

nut (21) to 270-285 N•m. (200-210 ft-lb).

4. Remove the piston assembly from the vise, but do

not lay it down on its side; doing so may dam-

age the seal.

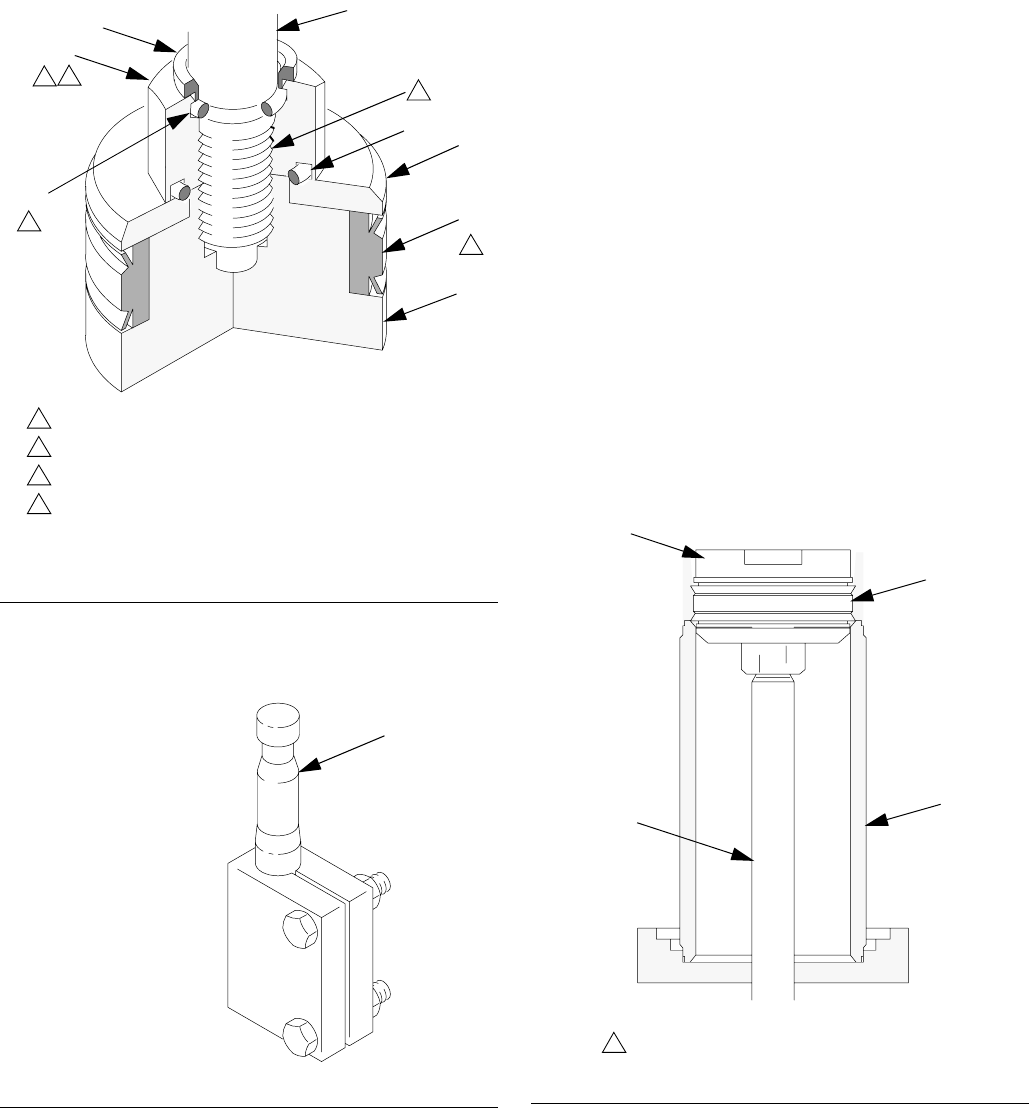

5. Carefully and evenly guide the seal and the piston

into the cylinder. The piston seal and piston may

need to be tipped at an angle and the exposed,

leading lip of the seal tapped into the cylinder with a

plastic mallet. After the seal lip has entered the cyl-

inder use an arbor press or tap the bottom of the

piston assembly lightly with a plastic mallet to slide

the piston assembly into the cylinder. Before press-

ing, ensure the piston seal lips are started into the

cylinder. See F

IG

. 9.

6. Clean the remaining pump parts in a compatible sol-

vent.

F

IG

. 7. Piston Assembly

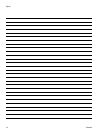

F

IG

. 8. Tool Kit 220385

TI0219

21

20

19

*22

23*

25*

26

24

Apply lubricant.

Torque to 200-210 ft-lb (270-285 N•m).

Apply lubricant to face of piston nut.

Apply high strength (red) Loctite

®

263 or 2760 to entire

length of threads. Sealant must be allowed to cure for a

minimum of 12 hours before use.

1

3

4

8

8

1

3

4

1

01413

19

Tighten the tool on the

widest part of the shaft

(19). Grip the tool with

a wrench and unscrew

the shaft.

F

IG

. 9. Install Piston in Cylinder

25

4

19

26

1

Do not damage edges of seal.

TI0221