16 Generac

®

Power Systems, Inc.

CHANGING ENGINE OIL

Refer to maintenance performed by authorized service

facilities for engine oil and filter change frequencies.

Drain the oil while the engine is still warm from run-

ning. This means warm up the engine, shut it down and

drain immediately as follows:

1. Remove OIL DRAIN HOSE from its retaining clip.

2. Loosen and remove OIL DRAIN HOSE CAP. Drain

oil completely into suitable container.

3. When all oil has drained, install and tighten OIL

DRAIN HOSE CAP, and re-install into its retaining

clip.

4. Turn OIL FILTER (Figure 4.3) counterclockwise and

remove. Dispose of old filter.

Figure 4.3 - Oil Filter

5. Apply light coating of new engine oil to seal of new

oil filter. Install FILTER and tighten by hand only.

DO NOT OVERTIGHTEN.

6. Remove OIL FILL CAP. Add recommended oil (see

SPECIFICATIONS). DO NOT FILL ABOVE THE DIP-

STICK “FULL” MARK. Crankcase oil capacity is 4.0

U.S. quarts (3.8 liters).

After refilling the crankcase with oil, always check

oil level on dipstick. NEVER OPERATE ENGINE

WITH OIL BELOW THE DIPSTICK “ADD” MARK.

7. Start engine and check for oil leaks.

CHANGING THE ENGINE AIR CLEANER

To replace the engine air cleaner, (part number 59402),

simply remove the air cleaner cover and replace the air

filter making sure it is positioned properly before reat-

taching the cover (Figure 4.4).

Figure 4.4 – Engine Air Cleaner

See the “Service Schedule,” Section 6, for air cleaner

maintenance.

SPARK PLUGS

Reset the spark plug gap or replace the spark plugs as

necessary. See Section 6.

1. Clean the area around the base of the spark plugs to

keep dirt and debris out of the engine. Clean by

scraping or washing using a wire brush and com-

mercial solvent. Do not blast the spark plugs to

clean.

2. Remove the spark plugs and check the condition.

Replace the spark plugs if worn or if reuse is ques-

tionable. See the “Service Schedule,” Section 6, for

recommended inspection.

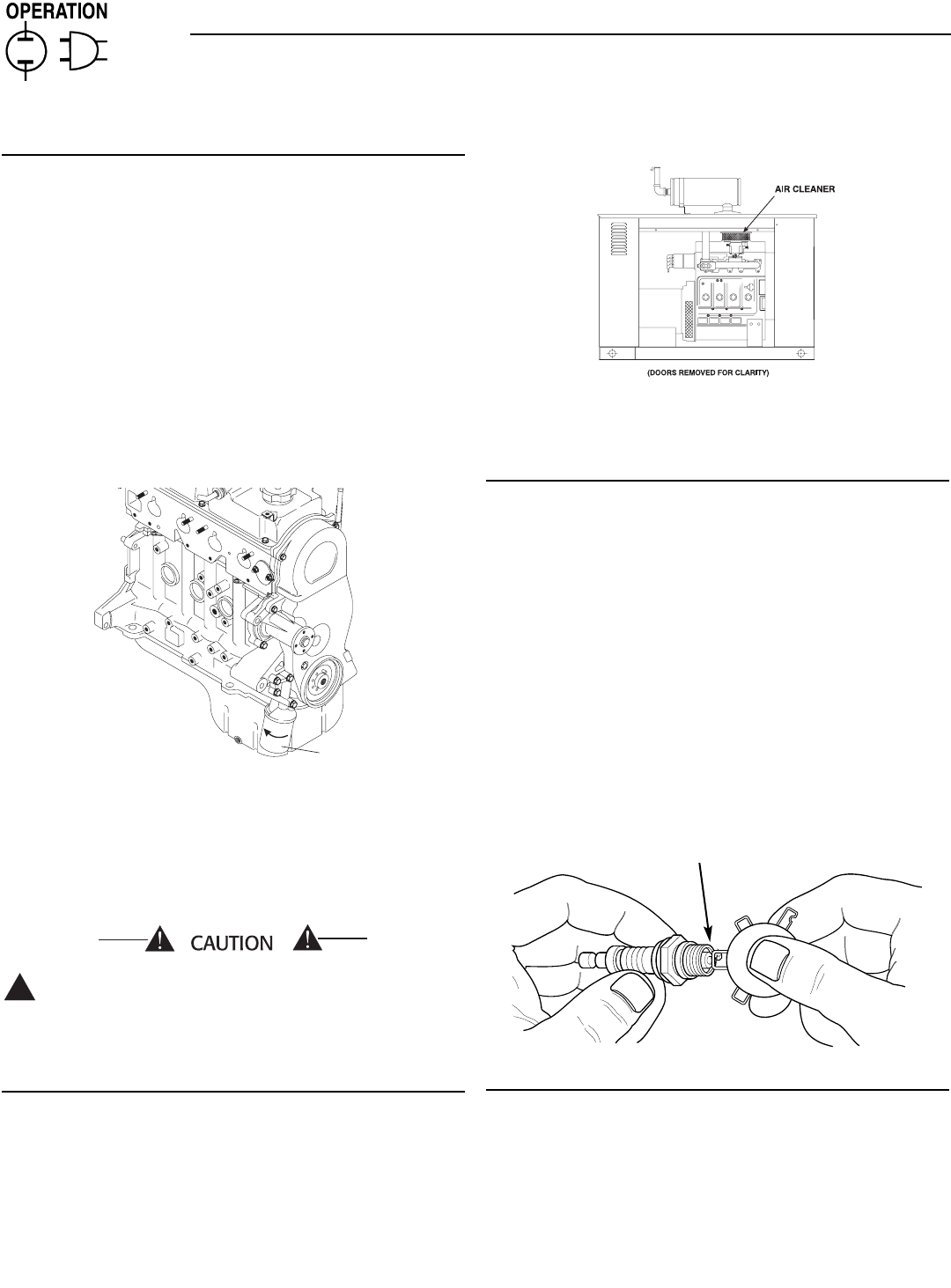

3. Check the spark plug gap using a wire feeler gauge.

Adjust the gap to 0.5-0.6 mm (0.020-0.025 inch) by

carefully bending the ground electrode (Figure 4.5).

Figure 4.5 – Setting the Spark Plug Gap

COOLANT CHANGE

Every year, have Authorized Service Facility drain, flush

and refill the cooling system. See SPECIFICATIONS for

cooling system recommendations.

!

OIL FILTER

Section 4 — Maintenance

Guardian Liquid-cooled 15 kW, 20 kW and 25 kW Generators

SET PLUG GAP AT 0.5-0.6 mm

(0.020-0.025 inch)