ENGINE COOLANT

Check coolant level in coolant recovery bottle. See the Specifications

and Service Schedule sections.

Add recommended coolant mixture as necessary.•

Periodically remove radiator pressure cap (only when engine •

has cooled down) to make sure the coolant recovery system

is functioning properly. Coolant should be at bottom of radia-

tor filler neck. If coolant level is low, inspect gasket in radiator

pressure cap. Replace cap, if necessary. To have pressure cap

tested, contact a Service Facility. Inspect cooling system and

coolant recovery system for leaks.

COOLANT CHANGE

Every year, have a service facility drain, flush and refill the cooling

system. See the Specifications and Service Schedule for cooling

system recommendations.

OVERLOAD PROTECTION FOR ENGINE DC ELECTRICAL

SYSTEM

Engine cranking, start up and running are controlled by a solid

state Engine Controller circuit board. Battery voltage is delivered

to that circuit board via the control panel fuse. This overcurrent

protection device will open if the circuit is overloaded.

n

If a circuit breaker opens or a fuse element

melts, find the cause of the overload before

resetting the circuit breaker or replacing the

fuse.

EXERCISE SYSTEM

Starts the Stationary Emergency Generator engine once every

seven days and lets it run for 12 minutes.

PERFORM VISUAL INSPECTION

Complete a thorough visual inspection of the entire engine-genera-

tor monthly. Look for obvious damage, loose, missing or corroded

nuts, bolts and other fasteners. Look for fuel, oil or coolant leaks.

INSPECT EXHAUST SYSTEM

Inspect the exhaust system at least once every year. Check all

exhaust system pipes, mufflers, clamps, etc. for condition, tight-

ness, leaks, security, damage.

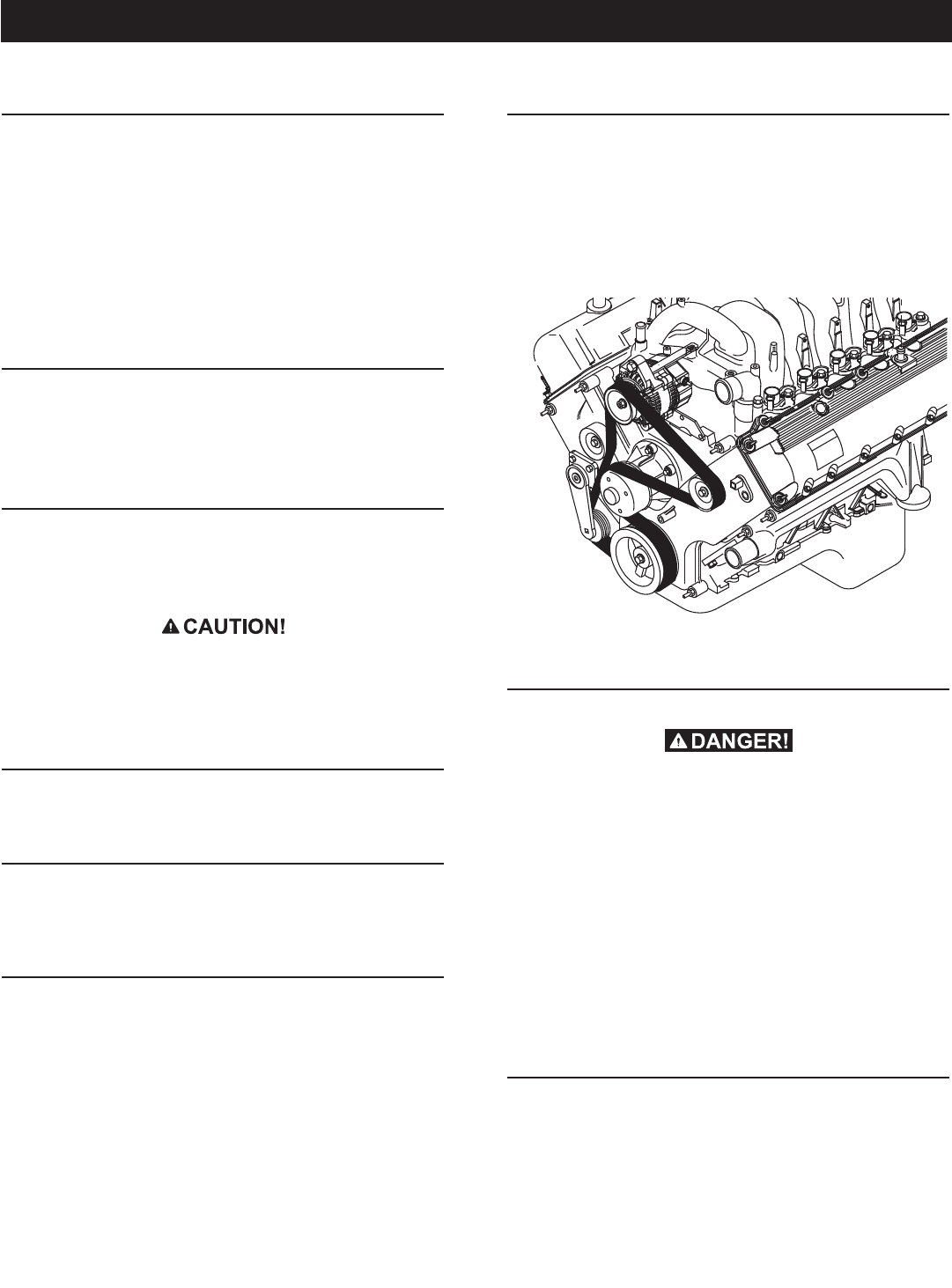

CHECK FAN BELT

Inspect fan belts every year. Replace any damaged, deterio-•

rated, worn or otherwise defective belt.

Check fan belt tension. Thumb pressure, exerted midway •

between pulleys, should deflect about 3/8 to 5/8 of an inch.

Adjust belt tension as required.

Check fan belt alignment (see Figure 10.2).•

Figure 10.2 – Fan Belt

INSPECT ENGINE GOVERNOR

Visually inspect electronic governor.

n

Do not attempt to adjust the governor. Only

qualified service facilities should adjust

the governor. Excessively high operating

speeds are dangerous and increase the

risk of personal injury. Low speeds impose

a heavy load on the engine when adequate

engine power is not available and may

shorten engine life. Correct rated frequency

and voltage are supplied only at the proper

governed speed. Some connected electrical

load devices may be damaged by incorrect

frequency and/or voltage. Only qualified ser-

vice technicians should adjust the governed

speed.

CHANGING THE ENGINE AIR FILTER

To replace the engine air filter, remove the air filter cover and

replace the air filter making sure it is positioned properly before

reattaching the cover (Figure 10.3).

See the Service Schedule for air filter maintenance.

10-2

Maint029 Rev. A 10/10

Maintenance