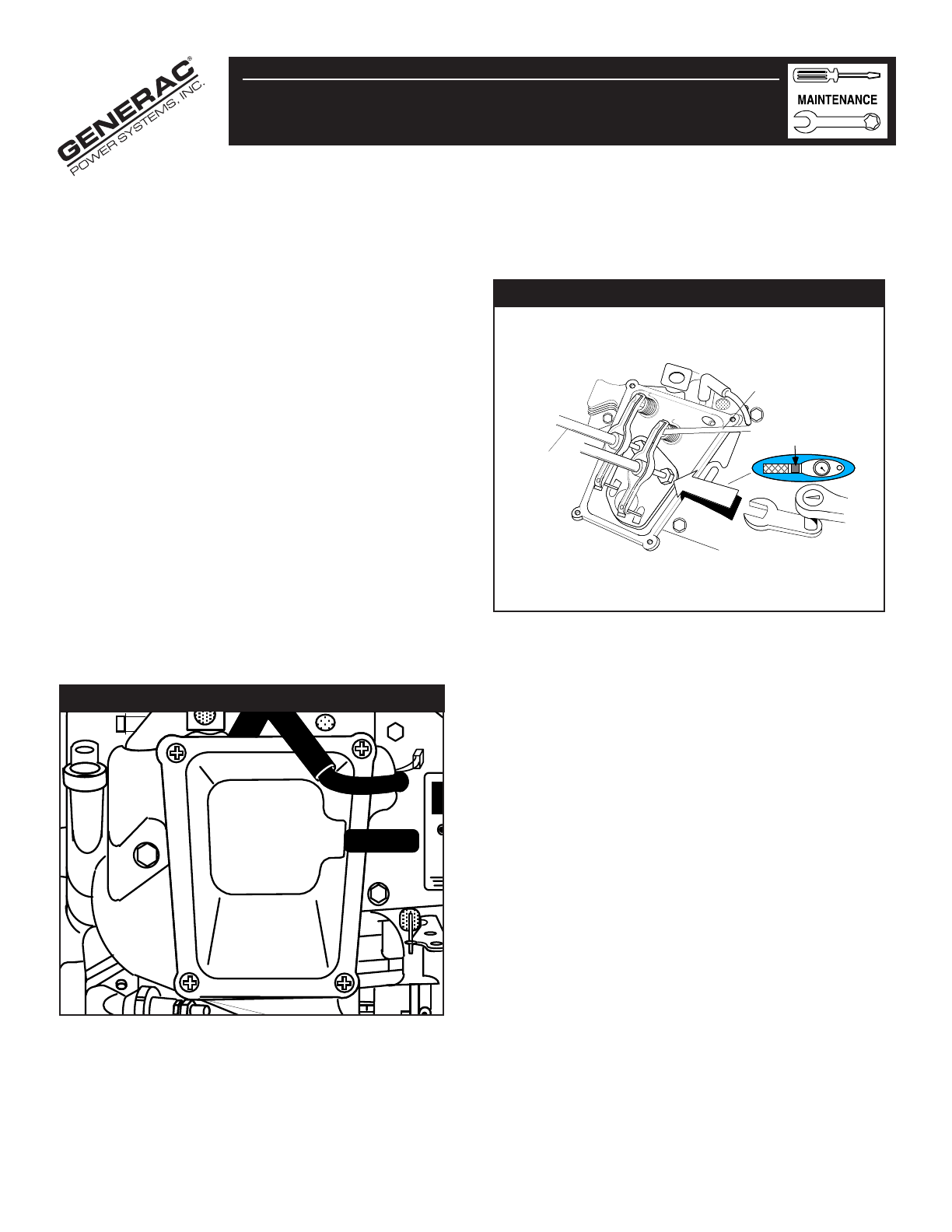

3. Loosen the rocker arm jam nut. Using an allen wrench to turn

the pivot ball stud, check the clearance between the rocker

arm and the valve stem with a flat feeler gauge (Figure 11).

Figure 11 — Adjusting Valve to Rocker Arm Clearance

4. When the valve clearance is correct, hold the pivot ball stud

with the allen wrench and tighten the rocker arm jam nut.

Torque the jam nut to 7.15-9.35 N-m (65-85 in-lb). After

tightening the jam nut, recheck the valve clearance to make

sure it did not change (see Figure 11).

5. Reinstall the rocker cover gasket, rocker cover and

the four (4) screws (see Figure 10).

Tighten Jam Nut to

65-85 inch-pounds

Allen Wrench

Feeler Gauge

Loosen Jam Nut,

GGeenneerraacc GGNN--119900//222200 EEnnggiinnee

— 11 —

CARBURETOR ADJUSTMENTS

The carburetor of your engine is pre-set at the factory. The

carburetor should not be tampered with because this will VOID

THE EMISSION CONTROL SYSTEM WARRANTY. If you

experience problems and your engine is used at an altitude in

excess of 5000 feet, contact the nearest authorized dealer

regarding high altitude setting changes.

CHECKING/ADJUSTING VALVE TO

ROCKER ARM CLEARANCE

Every 50 hours of operation, remove the rocker cover and

check the valve to rocker arm clearance.

When adjusting the clearance, the engine should be at room

temperature, and the piston should be at Top Dead Center

(TDC) of its compression stroke (both valves are closed). The

correct clearance is 0.05-0.1mm (0.002-0.004 in.). Check and

adjust the valve to rocker arm clearance as follows:

1. Remove the four (4) screws from the rocker cover

(Figure 10).

2. Remove the rocker cover and rocker cover gasket.

Figure 10 —Removing the Valve Cover

OHVI

LOW

OI