4. Remove the engine air in baffle located on the left-

hand side of the battery compartment. Two M6

screws are located on top of the baffle and two

M6 screws are located on the inside of the baffle

towards the back.

5. Remove the small hose clamp and hose from the

fuel regulator. It may be necessary to pry the hose

off of the brass fitting using a screwdriver to gen-

tly lift up the hose edge.

6. Remove the small brass hose fitting from the reg-

ulator casting.

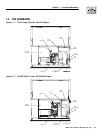

7. Place the small fuel jet, thread side first, into the

threaded hole originally occupied by the brass

hose fitting (Figure 1.4).

Figure 1.4 - Demand Regulator

8. Using a short No. 2 Phillips screw driver, thread

the small fuel jet into the regulator casting. Do

not over tighten.

9. Apply thread sealant to the threads of the hose fit-

ting and replace it into the regulator body.

10. Re-attach the small hose and hose clamp and

tighten as necessary.

11. Replace the engine air in baffle using the four M6

screws.

12. Identify both brass adjustment screws on the reg-

ulator.

NOTE:

One adjustment screw can be accessed from the

front of the unit and the second can be accessed

from the back of the unit enclosure by removing

the plastic hole plug. The screw can be turned

with a long flat blade screwdriver.

13. To adjust the system to run on LP fuel, turn

BOTH adjuster screws 1/2 TURN CLOCKWISE.

The system should now be set for maximum

power and best perfomance. DO NOT, UNDER

ANY CIRCUMSTANCES, REMOVE THE SET

PINS FROM THE REGULATOR HOUSING.

THIS WILL VOID THE WARRANTY.

14. It may be necessary to make minor adjustments

to the preset adjustment screw settings to achieve

maximum power, particularly at higher altitudes.

If experiencing problems with the unit producing

maximum power, follow the procedure in Section

2.6 (Adjusting the Fuel Regulator).

1.9 LOCATION

1.9.1 GENERATOR

Install the generator set, in its protective enclosure,

outdoors, where adequate cooling and ventilating air

is always available. Consider these factors:

• Install the unit where air inlet and outlet openings

will not become obstructed by leaves, grass, snow,

etc. If prevailing winds will cause blowing or drift-

ing, consider using a windbreak to protect the unit.

• Install the generator on high ground where water

levels will not rise and endanger it.

• Allow sufficient room on all sides of the generator

for maintenance and servicing. A good rule is to

allow three feet of space on all sides.

• Where strong prevailing winds blow from one

direction, face the generator air inlet openings to

the prevailing winds.

• Install the generator as close as possible to the fuel

supply, to reduce the length of piping.

• Install the generator as close as possible to the

transfer switch. HOWEVER, REMEMBER THAT

LAWS OR CODES MAY REGULATE THE DIS-

TANCE.

1.9.2 TRANSFER SWITCH

1.9.2.1 7 kW, 12 kW and 15 kW Units

Transfer switches for use with these generators are

sold separately and can be purchased from Generac

Authorized Dealers.

• Install the transfer switch on a firm, sturdy sup-

porting structure.

• To prevent switch distortion, level the switch if nec-

essary. This can be done by placing washers

between the switch enclosure and mounting sur-

face.

• Never install the switch where water or any corro-

sive substance might drip onto the enclosure.

• Protect the switch at all times against excessive

moisture, dust, dirt, lint, construction grit and cor-

rosive vapors.

• Failure to utilize a Generac transfer switch with

this generator may void the warranty.

◆

◆

BRA

SS

H

OS

E

FITTIN

G

IDLE

C

IR

CU

I

T

P

O

R

T

U

1

T

TAP

1

/8

NP

T

BRA

SS

H

OS

E

FITTIN

G

F

U

EL H

OSE

S

MAL

L

F

U

EL

J

E

T

RE

GU

LAT

OR

H

OUS

IN

G

P

O

R

T

AD

JUS

TE

R

SC

REW

S

OU

TLET P

O

RT

S

Section 1 — General Information

Generac Air-cooled 7 kW, 12 kW and 15 kW Generators

8 Generac

®

Power Systems, Inc.