Generac

®

Power Systems, Inc. 25

Section 6 – Installation

QUIETPACT 55, 65, and 75 Recreational Vehicle Generators

6.2.4 ACOUSTICS

For additional noise abatement, the installer may

wish to consider the following:

• Using special sound insulating materials.

• Construction of a special noise abatement com-

partment.

NOTE:

Any method used to reduce noise must not

adversely affect the flow of cooling and ventilating

air into or out of the compartment.

In addition to the effective use of sound insulating

materials, construction of a special noise abatement

compartment might be considered to reduce noise

levels. Such a compartment might be constructed as

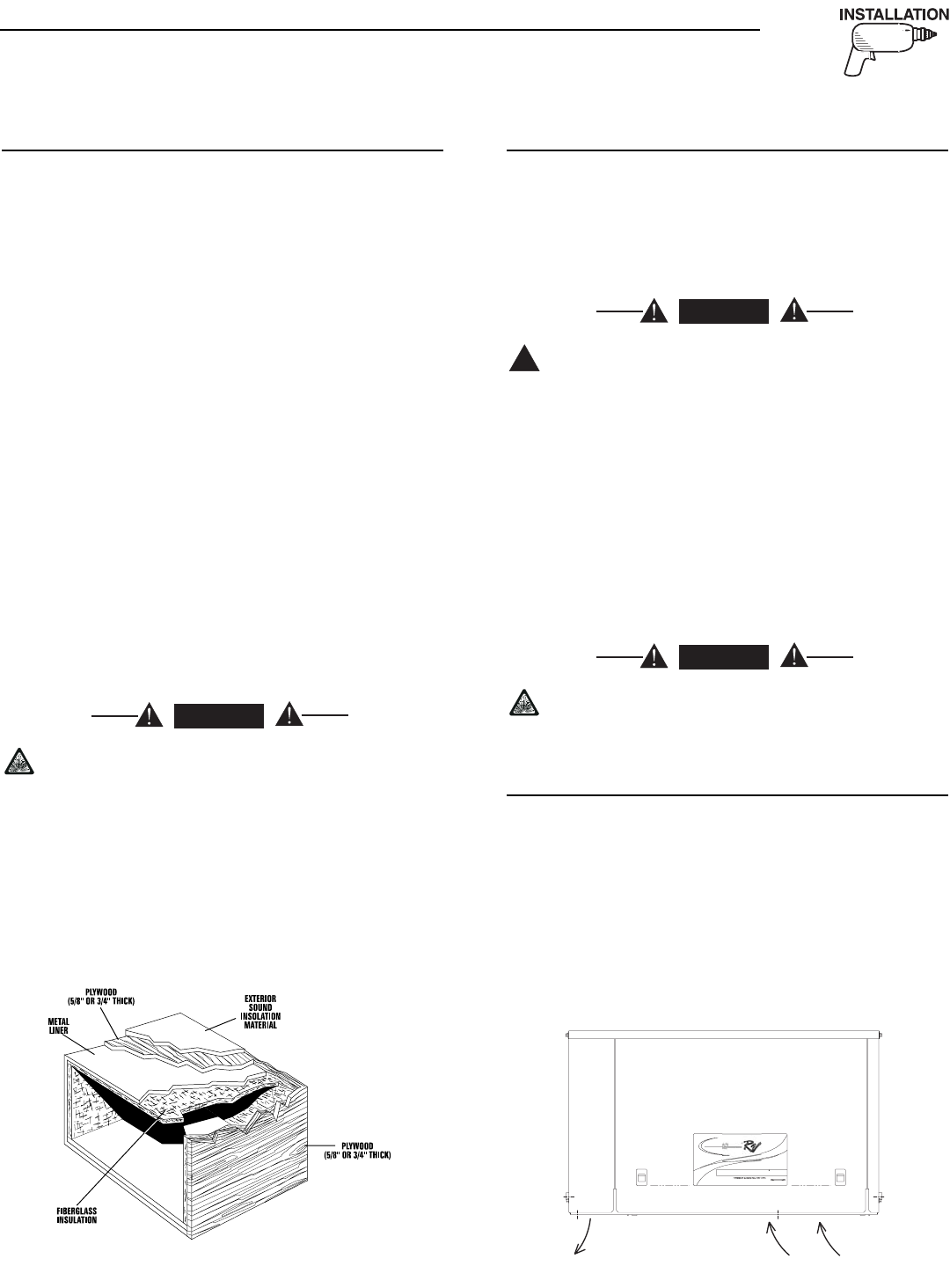

follows (Figure 6.7):

• Use 5/8-inch thick or 3/4-inch thick plywood in the

compartment.

• Construct the compartment floor of a double thick-

ness of 5/8-inch or 3/4-inch plywood.

• Line the compartment interior walls and floor, as

well as the underside of the floor, with 26-gauge

galvanized steel.

• Vapor seal all compartment seams and joints.

• Over the galvanized steel lining, install a combina-

tion of acoustical materials as mentioned in

Section 6.2.3.

To prevent fire or explosion, do not install any

insulation or other absorbent materials on the

interior or underside of the compartment floor.

• Seal all compartment door edges to prevent noise

leakage around the door perimeter.

• Line the compartment door interior (except for air

openings) with suitable, fireproof sound insulation

(such as 1-inch (25 mm) thick fiberglass with a 2-

pound density).

Figure 6.7 – Typical Noise Abatement

6.2.5 COMPARTMENT FLOOR CUTOUTS

You must provide openings in the generator compart-

ment for the following items (Figure 6.8, Page 26):

• Engine exhaust and cooling air outlets

• Generator cooling air inlet

• Four holes for passage of generator mounting

bolts. See Section 6.1.4 (Page 23).

Fuel lines and exhaust piping must not pene-

trate into the vehicle living area.

6.3 COOLING AND VENTILATING AIR

It is absolutely essential that an adequate flow of air

for cooling, ventilating and engine combustion be

supplied to the generator set. Without sufficient air-

flow, the engine/generator quickly overheats. Such

overheating can cause serious operating difficulties

and also may cause fire and personal injury. The

installer must make sure that sufficient air is avail-

able to the generator for cooling, ventilating and com-

bustion. The installer also must provide for a path

for exhausting the cooling air to the exterior of a com-

partment, if so equipped.

Never use discharged cooling air for heating or

permit such air to enter the vehicle interior. This

air contains deadly carbon monoxide gas and

other poisonous, flammable or explosive gases.

6.3.1 GENERATOR AIRFLOW

Engine operation drives cooling fans for the two-stage

cooling air system. A pressure fan draws cooling air

into the top of the generator (Figure 6.9). This airflow

cools the engine/generator and electronic compo-

nents. The second part of the cooling system, a suc-

tion fan, draws air that is heated from a hot engine

into a collector pan at the base of the unit. This heat-

ed air (although cooler than exhaust muffler) is then

deflected out the bottom toward the ground.

Figure 6.9 – Airflow Through Engine/Generator

b

y

Generac Power S

y

st

e

Q

UIETPAC

T

IND

US

TRIA

L

55G

GU

ARDI

A

◆

DANGER

!

DANGER

◆

DANGER

◆