14

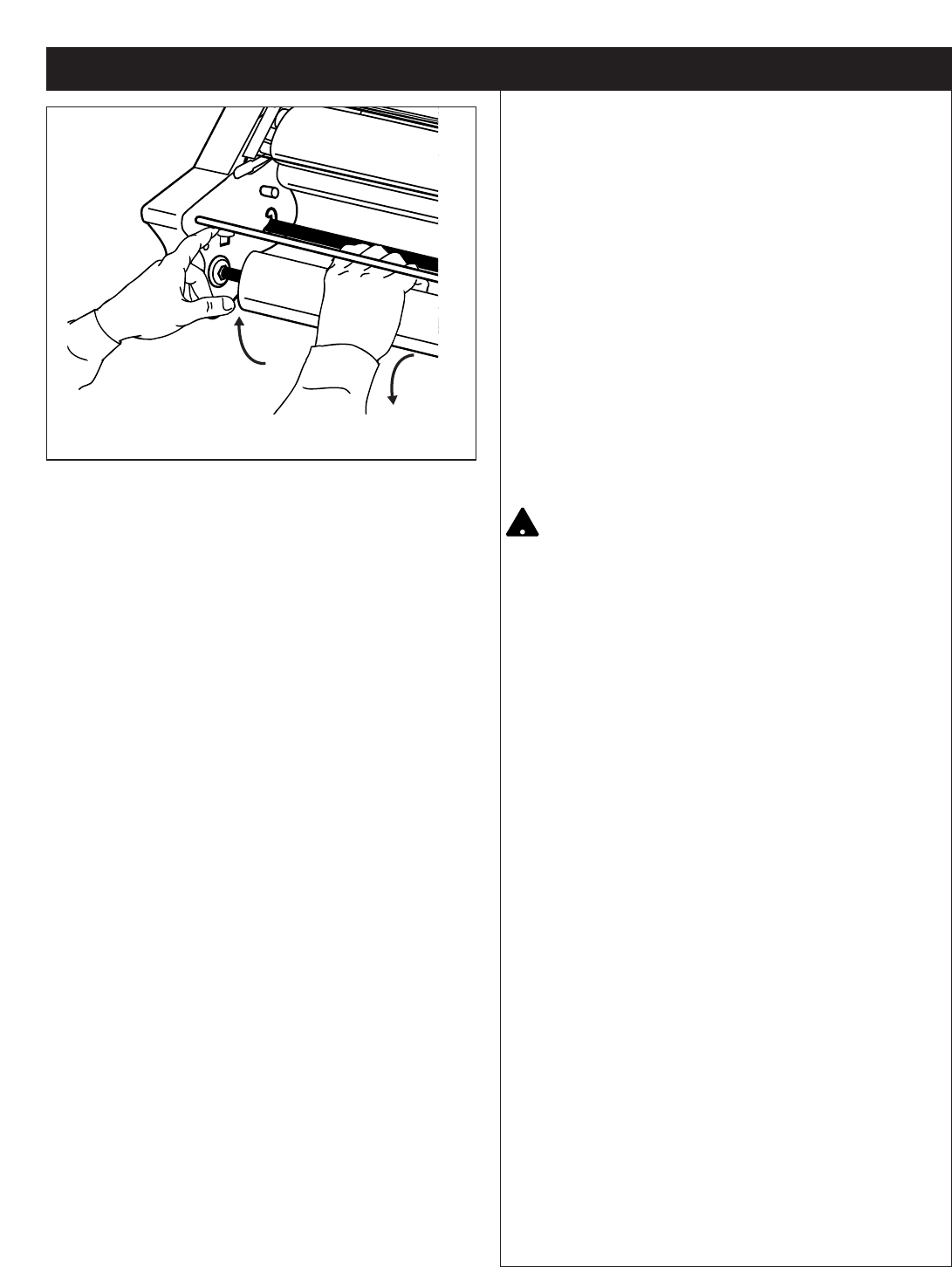

Figure 10

FILM TENSION ADJUSTMENT

The film should be taut. A properly adjusted roll of film should not

require excessive force to turn by hand. Film tension should be

enough to introduce a minor amount of drag as the film unrolls.

Insufficient tension causes wrinkles while too much tension

causes stretching (necking). Uneven tension between the top and

bottom rolls create curl. Too much upper tension creates upward

curl while too much bottom tension causes downward curl.

1. To adjust the bottom brake. Push and hold the brake lever,

(Figure 10), located on the left side frame by the roll of film.

Rotate the roll of film until the lever engages the internal

mechanism.

2. Refer to Figure 10 for the proper rotation of the film to

increase or decrease the tension.

3. Release the brake lever and check the tension by rotating

the roll of film. Resistance should be slight, not forced.

4. To adjust the top brake repeat steps 1 through 3.

5. Laminate some test samples to check for proper tension.

Further adjust if necessary.

CAUTION: Make sure safety shield and feed tray are

in the proper position to operate the unit.

OPERATION

Turn the power switch on. The power switch is located at the rear

of the machine.When the power switch is in the ON position, the

power indicator light on the control panel will be illuminated.

The laminator is now heating.

Use the Lamination Guide to select the correct speed for

your application.

When the laminator reaches operating temperature, the “Ready”

light on the control panel will be illuminated. Wait an additional

five minutes to allow for full heat saturation of the rollers.

This will insure good quality lamination.

Position the item(s) to be laminated on the Feed Table.

Push the “Run” button located on the control panel to run

laminating.

CLEARING A FILM JAM (Wrap-up)

Film jams (wrap-up) may occur if the film is loaded on backwards

or if the area at which film exits the equipment is blocked. The

film, when jammed, wraps around heat or pull rollers.To clear a

jam it is necessary to rotate the rollers in the reverse direction.

When pressed,

REVERSE on the control panel will cause the

rollers to go in reverse.To clear a jam:

1. Immediately stop the laminator by pressing

STOP.

2. Set the speed indicator to “1”.

3. Remove the feed tray and safety shield.

4. Cut the top and bottom film webs.

5. Grasp the loose ends of the web, pull straight out, install the

feed tray so the web is on top of the tray. Turn speed control to

“I”, then press

REVERSE and guide the film out of the

laminator.

6. Once the jam has cleared the heat shoes, press

STOP.

7. Thread the film per section FILM LOADING & THREADING.

INCREASE

AUGMENTER

INCREMENTO

DECREASE

DIMINUER

DISMINUCIÓN

!