Longer component life (inset photo)

New T-rod chain with 16,000 lbs. of tensile

strength, lasting up to twice as long as a T-bar

chain. (Standard on MS1223, MS1227, MS1231,

MS1237, and MS1243.)

Cast-special, steel-alloy apron idler slides offer

Design protects hydraulic lines

With the optional second hydraulic endgate cylinder, hydraulic lines run through

a 3x3 tube under the floor, eliminating the chance for punctures, tears, and leaks.

(Available on MS1223, MS1227, MS1231)

Hydraulic apron drive

Provides versatile load movement with variable speeds. Standard on the MS1256 and

MS1266, and optional on all other Frontier Heavy-duty Spreaders.

Two-speed apron drive

Includes low speed, high speed, and cleanout mode.

(Standard on MS1223, MS1227, MS1231, MS1237, and MS1243.)

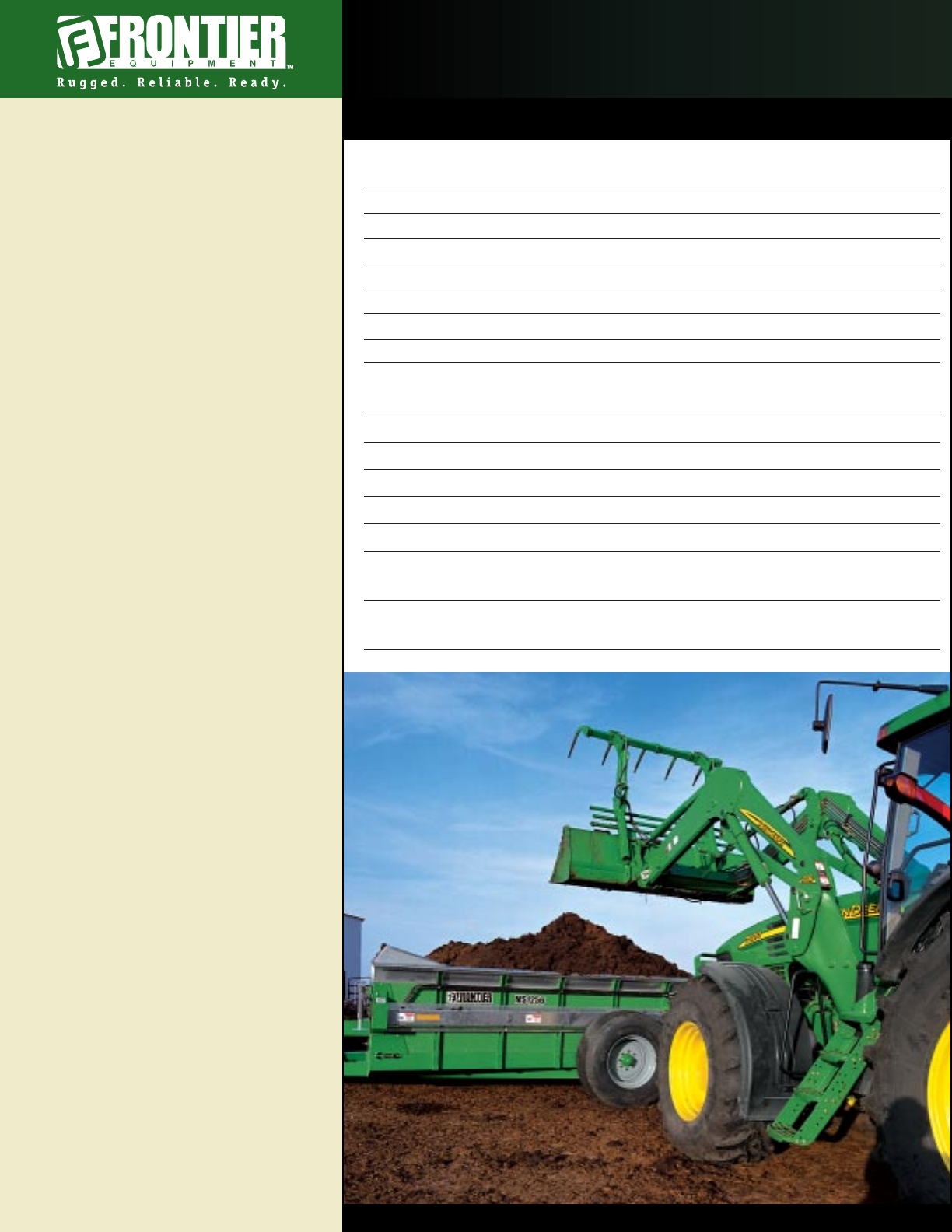

Introducing the all-new line

of Frontier Heavy-duty

Manure Spreaders, available

exclusively through your

John Deere dealer!

With

seven models from 235- to

660-bushel capacity, there’s a

rugged Frontier spreader that’s

just right for your operation.

These spreaders boast one of

the largest beaters on the

market – 29 inches in

diameter – for wide, uniform

spread patterns. Various

paddle assemblies deliver

greater spreading control;

blunt for widespread, and

sharp, ripper-type paddles

for more aggressive shredding

action. An optional top beater

makes easy work of high-

heaped loads.

Built-in strength for long

life, guaranteed!

Frontier

spreaders are constructed of

a massive welded frame,

reinforced with heavy floor

supports and side stakes for

tremendous strength and

durability. The entire spreader

box is poly-bonded for easy

cleaning and minimal freeze

up, and comes with a limited

lifetime warranty!* Check out

these tough-built spreaders at

your local John Deere

dealership today or visit us

at

www.BuyFrontier.com.

*Warranty subject to limitations. See operators manual

for warranty details.

All-new Frontier Manure Spreaders: Built tough for the long haul

Rugged, heavy-duty construction

Massive all-welded frame features heavy-duty floor and side stakes, and wrap-

around steel front corners. Rear main-beater side panels are welded to durable

5-inch U-channel side members for extra strength, reliability.

Easy cleaning, smooth unloading

Entire spreader box is poly-bonded to marine-type plywood for easy cleaning and

minimal freeze up, reducing the amount of torque needed to move heavier loads.

Versatile spreading action

Paddle assemblies match your material; blunt for wide spread patterns, and sharp,

ripper-type paddles for more aggressive shredding action.

Tackle high-heaped loads

Top beater makes easy work of high-heaped loads.

(Standard on MS1256 and MS1266, optional on all other heavy-duty models)

Years of dependable service

Spreader boxes are constructed of corrosion-resistant galvanized steel to ensure long

life. Poly-bonded floor and sides come with a limited lifetime warranty!*

*Warranty subject to limitations. See operators manual for warranty details.

BUSHEL CAPACITY AND UNLOAD SPEED

HEAVY-DUTY MANURE SPREADER FEATURES

Capacity Struck Level (cu. ft.) Heaped (bushel, old rating)

MS1223 143 235

MS1227 167 270

MS1231 185 310

MS1237 235 370

MS1243 275 430

MS1256 353 560

MS1266 479 660

Unloading Speed (per minute) High Speed Low Speed

MS1223 2-speed gearbox 8 ft. 9 in. 4 ft. 9 in.

MS1227 2-speed gearbox 8 ft. 9 in. 4 ft. 9 in.

MS1231 2-speed chain drive 8 ft. 8.5 in. 4 ft. 8.5 in.

MS1237 2-speed chain drive 8 ft. 8.5 in. 4 ft. 8.5 in.

MS1243 2-speed chain drive 8 ft. 8.5 in. 4 ft. 8.5 in.

MS1256 Variable-speed

hydraulic drive 0 ft. - 17 ft. 6 in. @16 GPM (no load)

MS1266 Variable-speed

hydraulic drive 0 ft. - 17 ft. 6 in. @16 GPM (no load)

Easy apron adjustment

Adjust the main apron by simply loosening the two side bolts and pulling up

the long bolt. Simple and fast.

Hydraulic endgate

Helps contain high-moisture loads and prevents spillage during transport.

(Optional on MS1223 and MS1227, standard on all other heavy-duty models)

Better cutting coverage

With one of the largest beaters on the market – 29 inches in diameter – these

spreaders cover more area from top to bottom to handle big loads with ease. Faster

tip-speed provides a wide, uniform spread.

Efficient load movement

Strong, double main-apron chain handles heavy loads with ease.

(Standard on MS1256 and MS1266)

Longer component life

Apron idler sprockets are made from rugged cast, steel alloy. They last far longer

than idler sprockets found on other spreaders.